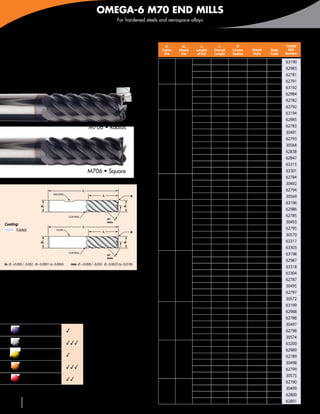

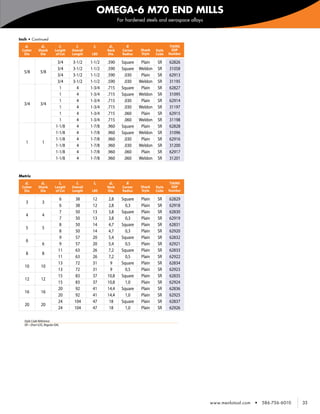

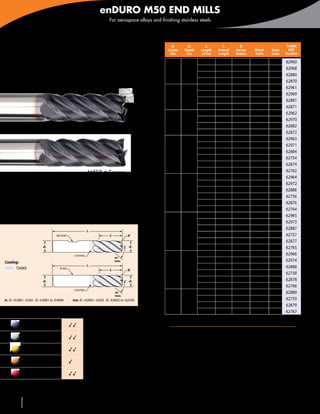

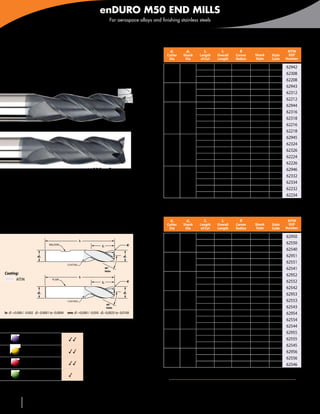

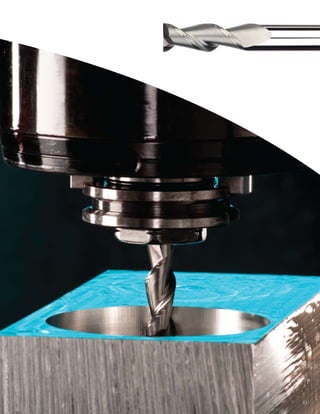

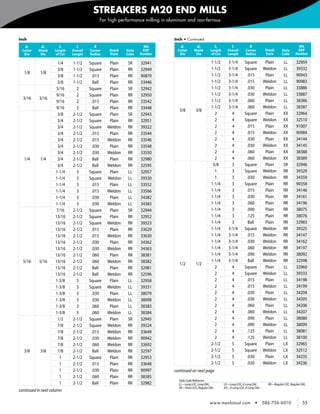

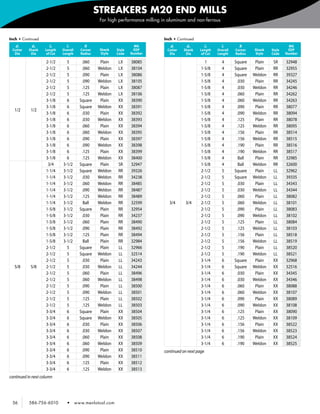

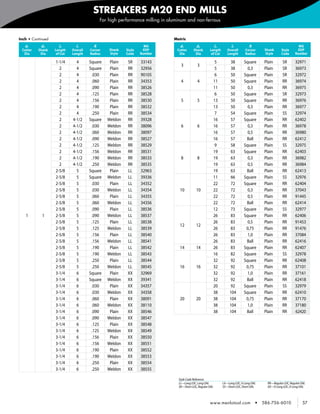

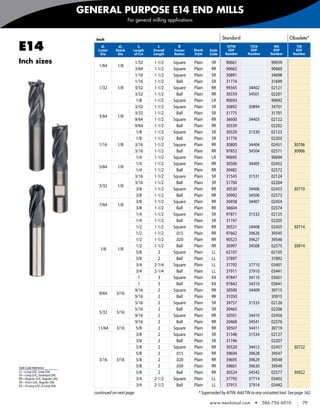

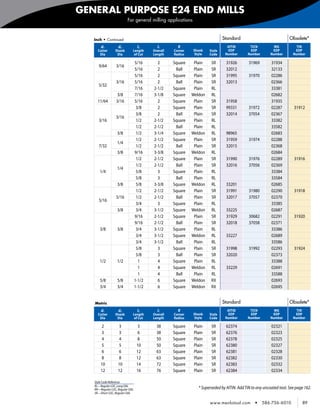

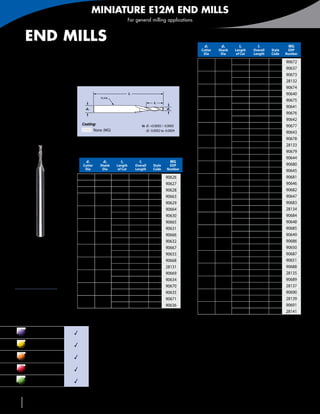

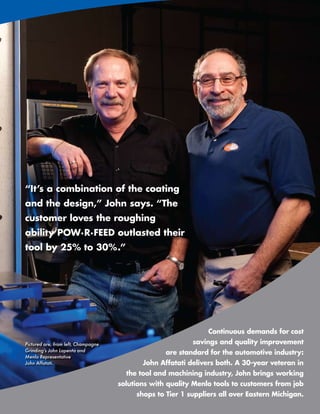

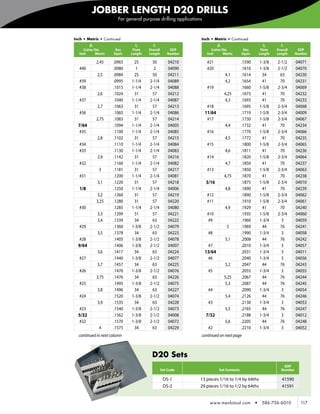

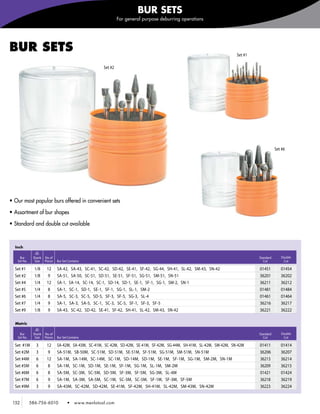

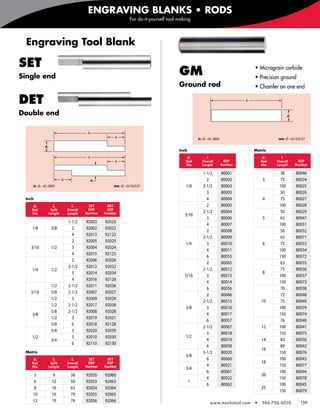

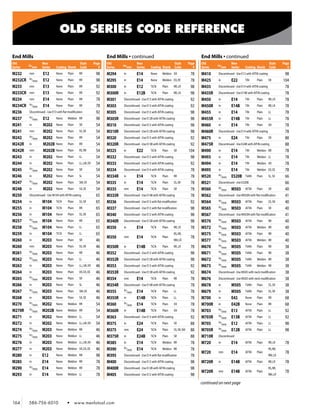

The document is the 2010 product catalog from Menlo Tool. It introduces new features of the catalog including easier to read tool charts, tool tips to save money and time, and case studies of how Menlo tools helped other shops. The catalog then provides an overview and index of the various high performance, specialty, and general purpose end mills, drills, reamers, and other tools offered. It also includes profiles of how Menlo tools helped reduce costs and improve productivity for various machine shops.