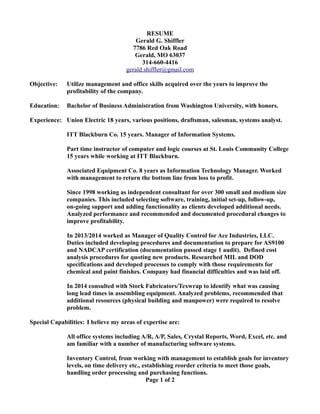

Gerald G. Shiffler has over 40 years of experience in management and information technology roles. He holds a Bachelor's degree in Business Administration from Washington University. Most recently, he worked as an independent consultant for over 300 small and medium sized companies, helping them select and implement software and improve profitability. Prior to that, he held management roles at Union Electric, ITT Blackburn Co., Associated Equipment Co., and Ace Industries. He has expertise in office systems, inventory control, labor and production control, scheduling, and financial analysis. His accomplishments include improving on-time delivery from 80% to 98% while reducing inventory 15% for one client.