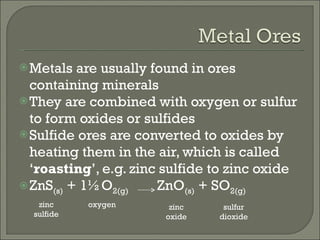

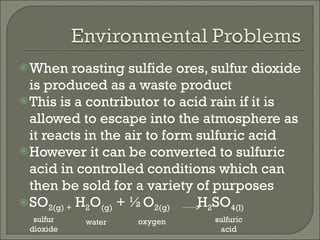

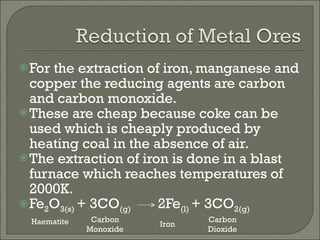

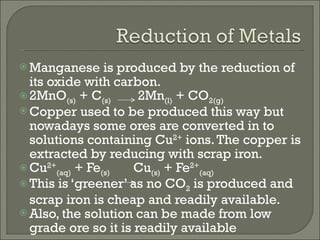

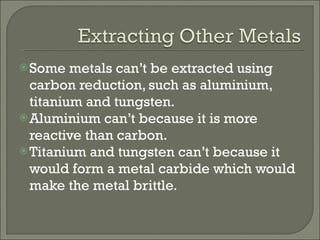

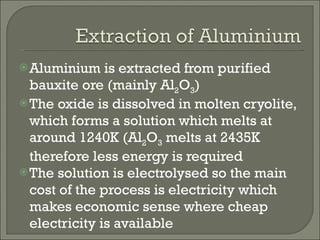

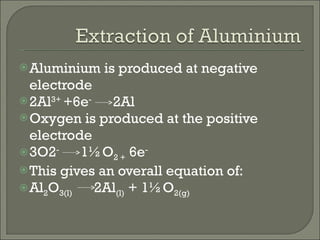

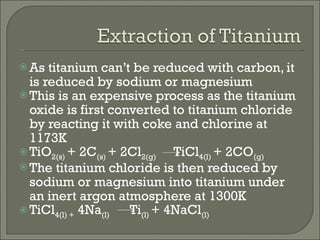

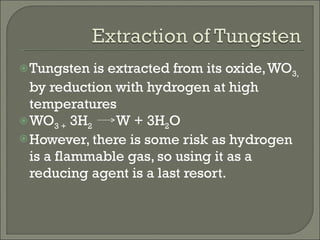

Metals are usually found as metal oxides or sulfides in ores. To extract the metal, the ore undergoes a reduction reaction where a reducing agent removes the oxygen. Common reducing agents include carbon, carbon monoxide, and hydrogen. Extraction of iron uses carbon in a blast furnace, while aluminum requires an electrolysis process due to its high reactivity. Recycling scrap metals provides environmental and economic benefits by reducing waste and saving energy compared to extracting from ores.