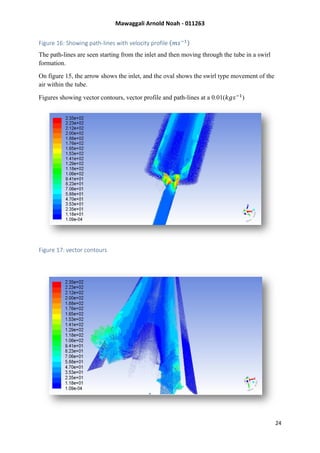

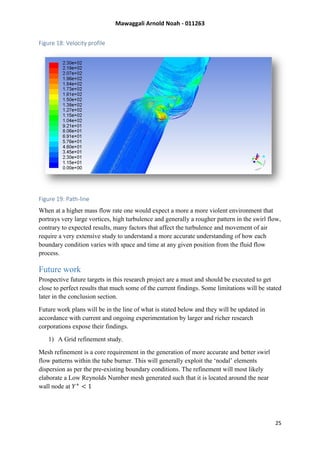

This document provides a progress report on a computational fluid dynamics (CFD) study of swirl flow in an industrial burner. It describes the use of k-ε turbulence models and hexagonal meshing to model airflow and analyze mass flow rates, vorticity, and velocity profiles within the burner geometry. Future work is planned to vary swirl flow parameters and investigate their effects on combustion.

![Mawaggali Arnold Noah - 011263

11

Figure 5: Showing a one-dimensional application of the continuity equation which cannot be

applied in our calculations because the inlet and outlet points does not vary with time. (ref:

https://www.princeton.edu/~asmits/Bicycle_web/continuity.html)

However, the instantaneous equation of motion as shown below, show a representation of the

fluid motions where the continuum approximation is valid or governed by a set of dynamic

equations referred to as the continuity and momentum equations.

Note: It is apparent that the (U)RANS is applied in our assumptions. This is because we are

not assuming a steady state scenario i.e. Since in fluid dynamics, the continuity equation

states that, in any steady state process, the rate at which mass enters a system is equal to the

rate at which mass leaves the system, but we cannot make such assumptions since accuracy is

the reason as to why so much research is carried out and not to mention the space and time

variations with velocity as elucidated in the formulae below;

[

𝜕𝜌̃

𝜕𝑡

+ 𝑢̃𝑗

𝜕𝜌̃

𝜕𝑥 𝑗

] + 𝜌̃

𝜕𝜌̃

𝜕𝑥 𝑗

= 0 (7)

[

𝜕𝑢̃ 𝑖

𝜕𝑡

+ 𝑢̃𝑗

𝜕𝑢̃𝑖

𝜕𝑥 𝑗

] += −

𝜕𝜌̃

𝜕𝑥 𝑗

+

𝜕𝑇̃ 𝑖𝑗

(𝑣)

𝜕𝑥 𝑗

(8)

Where 𝑢̃ 𝑖 = 𝑢̃ 𝑖(𝑥⃗, 𝑡), a function of space 𝑥⃗ and time t. 𝜕𝑇̃𝑖𝑗

(𝑣)

(𝑥⃗, 𝑡) is referred to as the

viscous stress tensor. (Tensor used in continuum mechanics to model the part of the stress at a

point within a material that can be attributed to the strain rate and the rate at which it is

deforming around that point) this enables us to predict the potential weakness points in the

material used against factors like temperature and pressure.

Numerically it’s referred to as a fourth-order viscosity tensor (𝜇) such that 𝜀 = 𝜇𝐸. Where E

– strain rate, 𝜀-viscous stress (nomenclature)

The Newtonian closure for the viscous stress tensor relates it to the fluid motion using a

property of fluid, molecular viscosity (𝜇).

𝑇̃𝑖𝑗

(𝑣)

= 2𝜇(𝑠̃𝑖 𝑗 −

1

3

𝑠̃ 𝑘 𝑘 𝛿̃𝑖𝑗) (9)

Where 𝑠̃ 𝑖 𝑗 is the instantaneous strain rate tensor defined as;

𝑠̃𝑖 𝑗 =

1

2

(

𝜕𝑢̃ 𝑖

𝜕𝑡

+ 𝑢̃𝑗

𝜕𝑢̃ 𝑖

𝜕𝑥 𝑗

) (10)

In the case for incompressible flows, the derivative of density following the fluid material is

zero

𝜕𝑢̃𝑖

𝜕𝑥 𝑗

= 0 (11)](https://image.slidesharecdn.com/37c3fd5d-0646-4a0a-9010-e1fee991357c-161229091748/85/MEng-Progress-Report-M-Arnold-11-320.jpg)

![Mawaggali Arnold Noah - 011263

12

[

𝜕𝑢̃ 𝑖

𝜕𝑡

+ 𝑢̃𝑗

𝜕𝑢̃𝑖

𝜕𝑥 𝑗

] = −

1

𝜌

𝜕𝜌̃

𝜕𝑥 𝑖

+

𝜕2 𝑢̃𝑖

𝜕𝑥 𝑗 𝜕𝑥 𝑗

(12)

We also use the URANS because as opposed to the detailed, very expensive and impractical

in industrial applications DNS (Direct Numerical Simulation), the URANS allows us to

analyse turbulent flow in two main parts.

𝑢̃ 𝑖 = 𝑈̅𝑖 + 𝑢𝑖

′

(13)

𝑝̃ = 𝑃̅ + 𝑝′

(14)

This approach is referred to as Reynolds Decomposition. These equations are inserted into

the instantaneous equations and hence averaging the results in the RANS equations.

𝜕𝑈̅ 𝑗

𝜕𝑥 𝑗

= 0 (15)

[

𝜕𝑢̃ 𝑖

𝜕𝑡

+ 𝑈̅𝑗

𝜕𝑈̅𝑖

𝜕𝑥 𝑗

] = −

1

𝜌

𝜕𝑃̅

𝜕𝑥 𝑖

+

𝜕2 𝑈̅ 𝑖

𝜕𝑥 𝑗 𝜕𝑥 𝑗

−

𝜕

𝜕𝑥 𝑗

{𝑢𝑖 𝑢𝑗̅̅̅̅̅} (16)

Importantly noted: the averages are referred to as ensemble at times, and this basically states

that they are time-dependent. i.e. the time dependent variables in equation (16) are both a

function of space and time.

𝑈 = 𝑈𝑖(𝑥𝑖, 𝑡), 𝑃 = 𝑃(𝑥𝑖, 𝑡), 𝑢𝑖 𝑢𝑗 = 𝑢𝑖 𝑢𝑗(𝑥𝑖, 𝑡) (17)

The term “𝑢𝑖 𝑢𝑗” defines the correlation between fluctuating velocities and is referred to as the

Reynolds stress tensor. When investigating the mean flow, all the turbulent fluid motion is

clustered into this single term by the (U)RANS process.

Further justification of using the (U)RANS model is that it provides us with ten unknowns in

total; 3-velocities, 1-pressure, 6-stresses and only and only four equations to tackle the whole

problem. 1=continuity, 3 components of Navier Stocks equation. This known as the

turbulence closure problem.

It is evident that the (Unsteady)RANS, gives us unsteady results, since we retain the transient

time response,

𝜕𝑈̅𝑖

𝜕𝑡

during the computation. The calculations are so time dependant that the

(U) is decomposed further into time dependant variables as shown below;

Time averaged part 〈𝑈̅〉, resolved fluctuation 𝑢′′

, and the modelled turbulent fluctuation 𝑢′

Hence 𝑢̃ = 𝑈̅ + 𝑢′

= 〈𝑈̅〉 + 𝑢′′

+ 𝑢′ (18)

The Eddy Viscosity model (EVM)

This model is use in the turbulence closure problem.](https://image.slidesharecdn.com/37c3fd5d-0646-4a0a-9010-e1fee991357c-161229091748/85/MEng-Progress-Report-M-Arnold-12-320.jpg)

![Mawaggali Arnold Noah - 011263

13

There are a various number of EVMs, and this depends on the application at hand. As in the

Newtonian closure for the viscous stress tensor, we use a similar idea to apply for turbulence

closure problem.

So, to close the RANS equation, an analogy that tries to relate the Reynolds stresses to the

fluid motion through what is referred to as “turbulent” or “eddy” viscosity is introduced and

referred to as the “Boussinesq assumption”.

It’s represented in the equation as bellow;

𝜌𝑢𝑖 𝑢𝑗̅̅̅̅̅ = −𝜇 𝑡 (

𝜕𝑈𝑖

𝜕𝑥 𝑗

+

𝜕𝑈 𝑗

𝜕𝑥 𝑖

) +

2

3

𝜌𝛿𝑖𝑗 𝑘 (19)

Basically, what this means is that the fluctuations are represented with a quantity that is kind

of averaged and then try to find out how the quantity is connected/coupled to the mean flow.

The EVM is a scalar quantity which is calculated using a turbulent velocity scale 𝒱, length

scale 𝑙, based on the dimensional analysis.

In the case of this projected length is one of the factors that would be varied in the future,

hence making it an appropriate fit for the numerical study.

𝑣𝑡 = 𝒱𝑙 (20)

In one EVM equation a solution for the turbulence quantity is probable and a second

turbulent quantity is derived from algebraic expression. These two quantities are what’s use

to describe “eddy” viscosity.

Two 𝑘 − 𝜀 models.

The k-epsilon model is one of the most used in CFD (Computational Fluid Dynamics). There

are a various number of these models used, though two are going to be talked about here. In

line with the above name formulae, the corresponding K-e model used was the Abe-Kondoh-

Nagano 𝒌 − 𝜺 model. 𝜀 appears naturally due to the dissipation rate of turbulent kinetic

energy and two equations for an EVM are most appropriate for the formation of 𝑣𝑡. Not to

mention the model is also a Low Reynolds Number (LRN) 𝒌 − 𝜺 model.

Equations are as follows;

𝜕𝑘

𝜕𝑡

+ 𝑈̅𝑗

𝜕𝑘

𝜕𝑥 𝑗

=

𝜕

𝜕𝑥 𝑗

[(𝑣 +

𝑣 𝑡

𝜎 𝑘

)

𝜕𝑘

𝜕𝑥 𝑗

] + 𝑃𝑘 − 𝜀 (21)

𝜕𝜀

𝜕𝑡

+ 𝑈̅𝑗

𝜕𝜀

𝜕𝑥 𝑗

=

𝜕

𝜕𝑥 𝑗

[(𝑣 +

𝑣 𝑡

𝜎 𝜀

)

𝜕𝜀

𝜕𝑥 𝑗

] + 𝐶𝜀1

𝜀

𝑘

𝑃𝑘 − 𝐶𝜀2𝑓2

𝜀2

𝑘

(22)

Where,

𝑃𝑘 = [𝑣𝑡 (

𝜕𝑈

𝜕𝑥 𝑗

+

𝜕𝑈̅ 𝑗

𝜕𝑥 𝑗

)]

𝜕𝑈̅ 𝑗

𝜕𝑥 𝑗

(23)](https://image.slidesharecdn.com/37c3fd5d-0646-4a0a-9010-e1fee991357c-161229091748/85/MEng-Progress-Report-M-Arnold-13-320.jpg)

![Mawaggali Arnold Noah - 011263

14

𝑣𝑡 = 𝐶𝜇 𝑓𝜇

𝑘2

𝜀

(24)

Plus

𝑓𝜇 = [1 − exp (−

𝑛∗

14

)]

2

[1 +

5

𝑅 𝑡

3

4

exp {− (

𝑅 𝑡

200

)

2

}] (25)

𝑓2 = [1 − exp (−

𝑛∗

3.1

)]

2

[1 + 0.3 exp {− (

𝑅 𝑡

6.5

)

2

}] (26)

𝑛∗

=

𝜀

1

4 𝑛

𝑣

3

4

(27)

Where ‘𝑛’ is the wall-normal distance between the node and the wall.

The constants in this model are as follows;

𝐶𝜇 = 0.09 𝐶𝜀1 = 1.5 𝐶𝜀2 = 1.9 𝜎𝑘 = 1.4 𝜎𝜀 = 1.4

Table 1: showing constants for the Abe-Kondoh-Nagano 𝐤 − 𝛆 model

Length scale for turbulence would be expressed as,

𝑙 =

𝑘

3

2

𝜖

(28)

We have the time scale as well, which is obtained using velocity scale and the length scale as

expressed bellow;

𝒯 =

𝑙

𝒱

=

𝑙

𝐾

1

2

=

𝐾

3

2

𝜀𝐾

1

2

=

𝑘

𝜀

(29)

The wall boundary conditions on this model

𝑈̅ = 𝑉̅ = 𝑘 = 0 (30)

And

𝜀 𝑤𝑎𝑙𝑙 = 2𝑣 𝑘1/𝑛1

2

(31)

Where ‘𝑛1’ is the normal distance between the wall and the closest wall node.

Other recommended 𝑘 − 𝜀 turbulence model

This can be applied is as bellow; (ref: Numerical Simulation of Swirling Flows -Heat Transfer

Enhancement)

The 𝑘 − 𝜀 RNG model is dominated by swirl and since this report is mainly focused on swirl,

it is quite safe to say that it is recommended for the turbulent numerical calculations.](https://image.slidesharecdn.com/37c3fd5d-0646-4a0a-9010-e1fee991357c-161229091748/85/MEng-Progress-Report-M-Arnold-14-320.jpg)