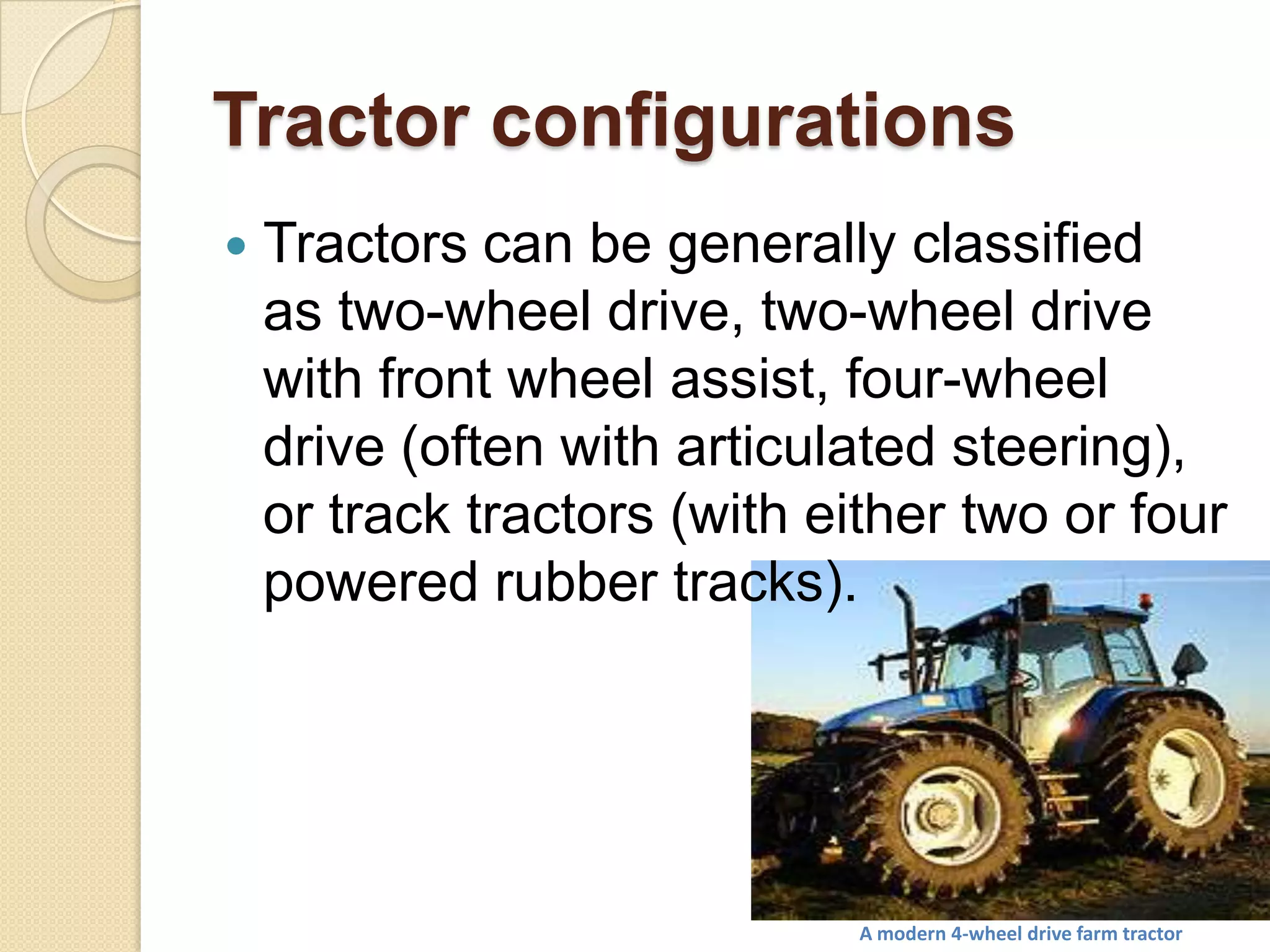

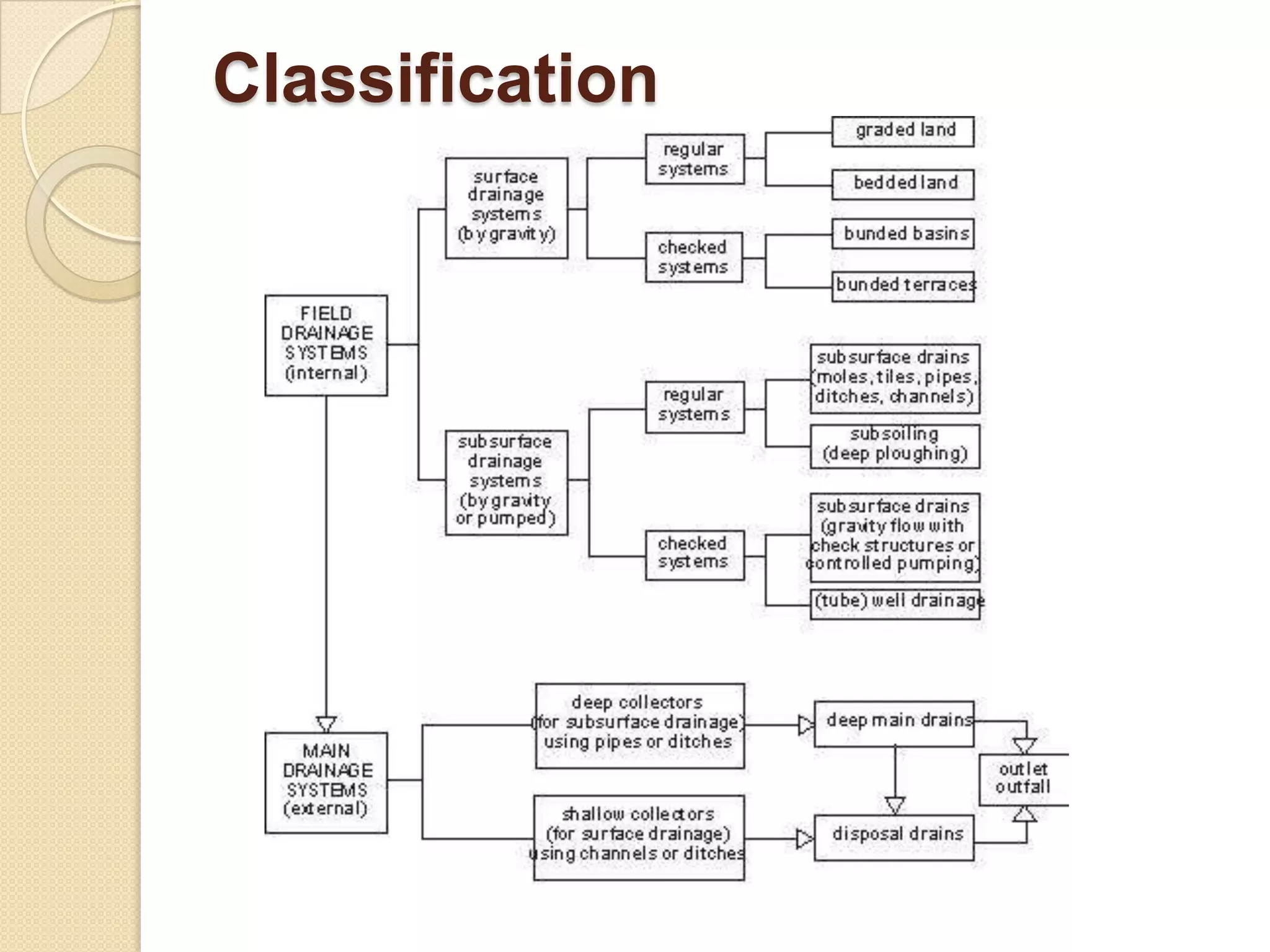

Mechanization in agriculture refers to the use of machinery to assist with farming tasks and operations. Over the past 300 years, there have been substantial advancements from manual labor and animal power to steam and gas-powered implements. This mechanization revolution dramatically reduced the percentage of the US workforce engaged in agriculture from 38% in 1900 to just 3% by the end of the 20th century. Common farm machinery includes tractors for plowing and tilling fields, tillage implements for soil preparation, planters for seeding crops, sprayers for applying fertilizers and pesticides, and combines for harvesting grains. Additional mechanized systems support irrigation to provide water and drainage to control field water levels for optimal crop production.