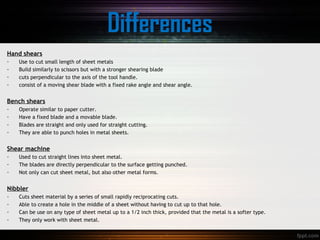

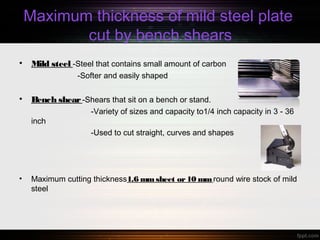

Mechanical cutting uses power-driven machines like lathes, milling machines, and drill presses to shape and form materials according to a predetermined design. Some common tools for cutting sheet metal include hand shears, bench shears, shear machines, and nibblers. Bench shears can be used to cut straight lines, curves, and shapes in mild steel plates up to around 1.6 mm thick. Different tools are suited for cutting different materials and thicknesses.