MC-SC-HSE-HIRA-000 Installation of Sanitary waste and venting piping system.docx

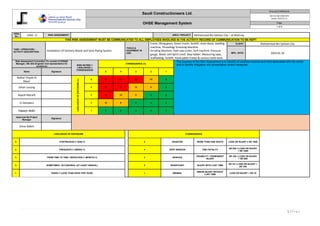

- 1. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 1 of 9 1 | P a g e HIRA No.: HIRA - 0 RISK ASSESSMENT: AREA / PROJECT: Mohammed Bin Salman City – Al Mishraq THIS RISK ASSESSMENT MUST BE COMMUNICATED TO ALL EMPLOYEES INVOLVED IN THE ACTIVITY RECORD OF COMMUNICATION TO BE KEPT TASK / OPERATION / ACTIVITY DESCRIPTION: Installation Of Sanitary Waste and Vent Piping System TOOLS & EQUIPMENT IN USE: Crane, lifting gears, boom trucks, forklift, chain block, welding machine, Threading/ Grooving Machine Grinding Machine, Hole saw cutter, Drill machine, Pressure gauge, Water and Spirit Level, Step ladder, Measuring tape, Scaffolding, Forklift, Hand pallet trolley & various hand tools. CLIENT: Mohammed Bin Salman City IMPL. DATE: 2024.01.16 Risk Assessment Committee (To consist of OHS&E Manager, CM, Site Engineer and representative for workforce) RISK RATING = LIKELIHOOD x CONSEQUENCE CONSEQUENCE (C) The purpose of this Risk Assessment is to identify all possible hazards and risks associated with the works and to identify mitigation and preventative control measures. Name Signature 5 4 3 2 1 Nidhal Thiyab Al Masri LIKELIHOOD OF EXPOSURE (L) 5 25 20 15 10 5 Johan Lessing 4 20 16 12 8 4 Rajesh Marath 3 15 12 9 6 3 CJ Dempers 2 10 8 6 4 2 Hazem Aldiri 1 5 4 3 2 1 Approved By Project Manager Signature Omar Balkhi LIKELIHOOD OF EXPOSURE CONSEQUENCE 5 CONTINUOUSLY (DAILY) 5 DISASTER MORE THAN ONE DEATH LOSS OR INJURY ≥ SR 100K 4 FREQUENTLY (WEEKLY) 4 VERY SERIOUS ONE FATALITY SR 50K ≤ LOSS OR INJURY < SR 100K 3 FROM TIME TO TIME / REPEATEDLY (MONTHLY) 3 SERIOUS DISABILITY / PERMANENT INJURY SR 10K ≤ LOSS OR INJURY < SR 50K 2 SOMETIMES / OCCASIONAL (AT LEAST ANNUAL) 2 SIGNIFICANT INJURY WITH LOST TIME SR 1K ≤ LOSS OR INJURY < SR 10K 1 RARELY (LESS THAN ONCE PER YEAR) 1 MINIMAL MINOR INJURY WITHOUT LOST TIME LOSS OR INJURY < SR 1K

- 2. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 2 of 9 2 | P a g e Ser No. TASK (What one does in logical steps) HAZARDS ASSOCIATED WITH EACH TASK (What can cause harm?) WHO CAN BE AFFECTED BY THE RISKS (per hazard and risks identified) WITHOUT CONTROLS WITH CONTROLS RESIDUAL RISK HARM / CONSEQUENCE (What can happen / go wrong?) A B C RISK RATING A B C RISK RATING LIKELIHOOD CONSEQUENCE RISK SCORE LIKELIHOOD CONSEQUENCE RISK SCORE 1. Planning Inadequate training, consultation and improvisation. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, re-work, minor to serious injuries. 4 5 20 High Method of work to be communicated. Planning of work to include input from the foreman and site engineer responsible for the operations. Works to be supervised by a competent foreman / supervisor. Planning of works to include equipment to be used. Documented procedures to be handed to the responsible foreman. Method of operation to be communicated to all employees involved in the task. The responsible foreman is to complete the daily STARRT card prior to start of task and communicate any additional hazards and controlled mentioned in STARRT card. Arrange training for threading/grooving machine, power tools or any additional equipment from manufacturer. Internal training to be arranged for work at height, manual handling, LOTO awareness, pallet trolley operation and fire prevention. 1 5 5 Low 2. Delivery of pipes and fittings and offloading. Arrangement for materials loading and offloading not in place. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, re-work, minor to serious injuries. 4 5 20 High Store keeper must coordinate with site team for storage area and stacking must be done properly with secured stillage to keep the pipes intact. Arrange suitable plants & equipment such tele handler, boom trucks or cranes for offloading materials. Truck driver must be inducted at gate and signed on driver’s instruction document. Allocate banks man for controlling delivery trucks and other equipment operation. Offloading area to be barricaded and control trespassing. 1 5 5 Low Poor management of plant and traffic movement leading to Run over by vehicle and plant; Hit by reversing equipment; Overhead obstruction Vehicle break down Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Property damage, minor to serious injuries. 5 5 25 High Delivery vehicle drivers shall be subjected to induction regarding traffic plan Ensure vehicle complete documentation is available with the driver. Pedestrian should use pedestrian accesses provided Appoint full time flagman provided with lighted batons at night No vehicle should reverse on site without the reverse light on and flagman on board. Never allow anyone to stay next to the moving plant and keep distance from materials being offloaded. Barricade 3 meter around equipment operation area. Allocate effective supervision to monitor the offloading. Stack pipes on rigid stillages to avoid slip and rolling down. Barricade location and ensure dunnage provided. Follow the supervisor’s instruction. 1 5 5 Low

- 3. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 3 of 9 3 | P a g e 3. Materials shifting by means of cranes, boom truck, telehandler. Uncontrolled operation. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, minor to serious injuries 5 5 25 High Ensure the riggers are trained and certified, and all the lifting gears intact (after inspection by the rigger) before operations commences. Proper hitches must be employed during lifting of pipes and use slings appropriate to the lifting operation. Lifting supervisor must advise. When moving, the load should not be raised more than necessary to maintain reasonable clearance from the ground. Comply lifting procedures and use of cranes/boom truck. MC-SC-HSE-HIRA-007 Boom Truck- HIAB Lifting operations/ MC-SC-HSE-HIRA-008 Mobile Crane Operations/ MC-SC-HSE-HIRA-076- Tower Crane Operations to be implemented and maintained at site. 1 5 5 Low Failure to secure the load; hit by the falling load or object Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, minor to serious injuries 5 4 20 High Secure the load with strap and use boxes to shift loose items. All webbing slings and lifting boxes must be inspected and certified by approved 3rd party service provider. 1 5 5 Low Open pits/excavation in the work area, fall from height. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, minor to serious injuries 5 4 20 High All open pits/excavations must be demarcated, sign posted and barricaded. Excavations to be illuminated during night. LED string line shall be fitted on the barrier for night shift operation. Safe access and egress must be provided to excavations and pits. 1 5 5 Low 4. Materials shifting by means of hand pallet trolleys. Uncontrolled movement of hand pallet trolley. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, Severe crush injuries 5 4 20 High Hand pallet trolley must be inspected prior to use and ensure fit for use. Trolley operators must be trained on safe use. Never use on inclined areas. Load should be secured on trolley and allocate sufficient number of employees to support the load. Avoid pinch points whilst moving. Defectives trolleys must be transferee in to quarantine area. 2 3 6 Low Horse play Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, Severe crush injuries 5 4 20 High Never horseplay on pallet trolley, responsible supervisor to retrain all operators to avoid horse play on it. 2 3 6 Low 5. Materials shifting by means of vertical stillage trolleys. Uncontrolled movement of stillage trolleys. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, Severe crush injuries 5 4 20 High Only use vertical stillage trolleys where pallet trolley not possible to shift materials. Load calculation to be acknowledged for scaffold tube stillage trolleys and ensure its not exceeding the safe working load. Check the wheel and ensure in good condition. Allocate sufficient number of employees to support the stillage. Mechanical support to be made at inclined area. 2 3 6 Low

- 4. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 4 of 9 4 | P a g e 6. Materials shifting manually. Pinch point and manual handling, Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, musculoskeletal disorder, hand injury cut and bruises 5 4 20 High All people should be trained for correct manual handling. Allocate sufficient number of employees to assist the load. Heavy duty hand gloves to be provided. Follow manual handling technique and limit load to be 20kg per person. Use the correct PPE for the task. Ensure full-sleeved coverall is worn by the workers manually handling of Piping materials to avoid injuries to the arms. Ensure excess amount or weights of Piping materials is not handled by individual workers during manual transport within the site or stores. Ensure vision is not blocked by Piping materials placed on shoulders during manual transport within the site or stores. Ensure manual transportation of materials on the staircase is well managed. Where required, use lifting equipment (slings, pulleys, material baskets etc) to lift pipes unto building floors. 2 3 6 Low 7. Material storage Poor house keeping causing slips trips and fall. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, musculoskeletal disorder, hand injury cut and bruises Ensure accesses are kept clear Housekeeping is regular Supervisor ensuring operatives are stacking material correctly Adequate lighting provided Appropriate space is allowed around storage areas.

- 5. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 5 of 9 5 | P a g e 8. Installation of sanitary waste and venting piping system. Work at height, falling from height, falling objects, overloading, protruding objects Access and egress Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, Traumatic brain and spine injuries, Paralysis, Broken bones, Organ damage, Loss of limbs etc. 4 4 16 High STARRT card briefing must be done before work commences Ensure PTW is in place Ensure proper working platform with fall protection in place Ensure full body harness with tie off Ensure scaffold platform are properly erected with ok to use tag Ensure castor wheels are locked Hand tools secured and tethered properly Avoid overreaching No unauthorised persons to modify scaffold Ensure 100% tie off above 1.8 meters. Persons not to lean over handrails. Maximum of two persons on the scaffold at any time. Workers to descend before any movement of the mobile scaffold. All materials on the scaffold to be secured – toolbox/containers etc. Materials on the ground to be placed away from general workers access/egress routes. Do not throw anything from or unto the scaffold- use material bags. Ensure free-standing, suspended materials that has not been coupled to larger suspended materials are secured to the support rods with thick nylon ropes before insulation commence. Never place any material on the top- or mid-rails of scaffolds. Keep pipes on the floor until you are set to install it at once. Correct PPE to be worn at all times. Secure step ladder whilst working on it. Never over reach on ladder rungs. Always ensure 3-point contact. Do not carry any materials in hand while climbing and descending. Ladder training to be conducted. 1 4 4 Low No or lack of competent people to operate power tools and poor selection of power tools. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Minor to Serious injuries Amputations 5 4 20 High Visually inspect tools before start of each working day. Tools to be inspected and colour coded as per procedure. Ensure good cable management, avoid tripping hazards. Use tools as per manufacturer’s instructions. Ensure drill bits are correct for the task. Ensure the RPM rating of the drills exceed the RPMs of the drill machine. Wear correct PPE for the task e.g. double eye protection when drilling. Keep appropriate distance from equipment’s working end when using – use the proper manual handling techniques. Select suitable bit for drill machine. All power tool users must be trained from manufacturer. Ensure handle and guard is in place whilst using. Select suitable disk for grinder. Provide power tools appropriate to the task at hand. Ensure housekeeping at all times. 1 4 4 Low

- 6. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 6 of 9 6 | P a g e Failure to obtain permit to work in shaft and confined spaces. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, minor to serious injuries 5 4 20 High Obtain permit for working inside the shaft. Lone working not allowed in shaft. In & out log should be maintained. Ensure overhead is protected. Provide adequate ventilation and lighting. Ensure safe working platform and access in place. Job rotation to be adopted and allocate watcher outside the shaft. Obtain permit to work inside the confined space. Gas monitoring to be conducted prior to enter. Allocate effective supervisor and trained watcher. Maintain in and out register. Ensure adequate ventilation and lighting in place. Perform hot work outside the confined space. Provide safe access. 1 4 4 Low Machine operating by un authorized employee, Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, minor to serious injuries (amputation/crush injuries) 5 4 20 High Only trained person operates the machine. The training will be delivered by manufacturer or supplier. Display the operator detail and training certificate at workplace. No training for unauthorised persons. 1 5 5 Low 8. Use of lubricant, solvent and paint No or lack of spill control leading to spillages on site. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, asphyxiation, Minor to serious injury. 4 4 16 High Ensure groups working with hazardous chemical are given internal training before engaging them on the job task. Ensure strict adherence to the lubricants, paint and solvents SDS and ensure workers are sufficiently familiarized with its content through daily TBT. Provide correct fire extinguisher nearby at all times at the work area. Ensure correct PPE is used for the task e.g. clear goggle, chemical masks, rubber gloves etc. Make sure sufficient signage is in place. A spill disposal kit shall be kept nearby at the paint workshop/ area/spot. Clear plastic sheets shall be placed underneath materials on which paint is being applied to collect scattered chemicals. Never carry out chemical applications simultaneously, or in close proximity to hot works. COSHH materials shall not be stored in excess of the quantity required for finishing tasks, on the site. Ensure correct storage of chemicals/paints at the work area. Provide adequate drip-trays for paint buckets. Ensure hazardous wastes are promptly and correctly disposed of. Ensure proper ventilation (forced or natural) is maintained at critical pipe painting locations. 1 4 4 Low 9. Cutting and joining pipes, cutting of steels to install pipes Hot work, use of defective hand tools and poor selection of hand tools that can cause fire. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, fire, ergonomics and repetitive Strain injury and maiming. 4 4 16 High Hot work permit to be obtained Proper access to be provided No work without edge protection or fall protection in place Supervision mandatory Inspection of area before permit to be issued. 1 4 4 Low

- 7. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 7 of 9 7 | P a g e Using chain block without inspection and certification. Being hit by falling object Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, Minor to serious injury. 5 4 20 High All chain blocks and lifting gears must be inspected and certified by approved 3rd party. SWL must be clearly marked. Lifting gears to be stored on hanging position. Ensure internal inspection and colour coding completed prior to use on site. Any defects on lifting device and gears must be discarded. Barricade pipe hoisting area until secure the installation. 1 5 5 Low Cutting and g r i n d i n gin elevated positions. Falling sparksand offcuts. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, fire, explosion, Minor to serious injury. 4 4 16 High When working in elevated positions with cutting equipment the use of fire blankets is compulsory, fire spotters must also be placed at lower levels as to warn others of the activity above and to extinguish any fires which s t a r tup as a result of falling sparks. No flammable or combustible materials in vicinity. Demarcation shall be erected to prevent persons entering the drop zone. A fire watcher shall remain in thework area up to ½ an hour after the task has been completed. 1 4 4 Low Fire / Explosion during electrical Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, fire, explosion, Minor to serious injury. 4 4 16 High Hot work permit must be taken and all precautions mentioned in the permit to be followed. Keep combustible materials away (11 meter / 35 feet) from hot work area, if not possible properly covered with fire resistant clothes / fire blankets. Do not carry out any hot work operation on a closed container. (E.g. Paint or chemical container). Battery power shall be disconnected prior to start any welding job on Plants, equipment’s and vehicles. Fire Protection systems / equipment’s to be made available prior to start any hot work. Protect the affected area with Fire Resistant Cloths to Contain Sparks / Hot Slag. A continues fire watch as recommended in the permit must be carried out after hot work. Connect the welding ground cable clamp to the work piece as close as possible to the area being welded. Keep all electrical cables are in good condition, and ensure all terminals are fastened properly. Do not carry out any hot work operations in confined space before taking adequate safety measures. All hot works to be closely monitored by a competent supervisor. Area HSE officer to check randomly. The electrode to be removed when it was being not used to avoid unintentional contact. A fire-resistant container will be provided for spent electrode stubs. Ensure equipment is calibrated as per the required duration. 1 4 4 Low

- 8. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 8 of 9 8 | P a g e Failure to inspect electrical equipment leading to electrocution. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Time delays, financial loss, property damage, re-work, fire, burns, cardiac arrest, seizures etc. Minor to serious injury. 5 4 20 High Electric in charge to check welding machine, electric cables to ensure they are fit to use. Do not put the cables through wet surface. All electrical equipment’s to be connected through ELCB and body to be grounded or double insulated. Standard industrial type plug & sockets to be used for connection. Terminal connection box to be well insulated / covered. Do not touch the electrode / metal parts of the electrode holder with skin or wet cloth. Do not touch your body on the electrode and work piece / welding ground clamp at a time. Do not operate the machine with covers removed / opened. Connect the welding ground clamp to the work piece as close as possible to the area being welded. PPE (Hand gloves) to be used and ensure it is not wet. Ensure equipment inspected by competent person and colour coded. Defective equipment will be removed from use and arrangement for repair will be made. Electric welding cables are to be kept as short as possible and routed away from pedestrian walkway areas. Electric welding operations will only be undertaken with earth return electrodes connected to the work piece. All connections between welding equipment and welding cables will be securely bolted. Pipelines containing electrical cables will not be used as a ground. Welding machines will be turned off when being moved or when the equipment is not in use. 1 4 4 Low No work permit Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Property damage, time delays, financial loss, minor injuries, possibility of fatality. 4 4 16 High The responsible foreman is to ensure that the required work permit has been obtained and signed prior to start of the work. HSE Officer to verify that the required inspections as indicated on the work permit has been done. Work cannot proceed until the PTW has been signed off by a competent person. MC-SC-HSE-HIRA-046 Hot Work Operation Day and Night shift works to be implemented and maintained at site. 1 4 4 Low Work at Heights Mobile elevating work platform Collision. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Lacerations, cuts, fracture, disability and fatality. Property damage. 5 4 20 High All MEWP movement and lifts to be controlled by certified Banks man / Rigger. Only Trained WAH personal shall perform the task. QC team to ensure any WAH is carried out with site specific safety requirements. Area to be demarcated. Conduct risk awareness through TBT. Conduct TBT training to include the use of MEWP. MEWP / platform areas and braces be protected from vehicular movement. Restrict the movement of mobile equipment. 1 5 5 Low Shaves, sharp objects/edges, etc. protruding from pipes. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Laceration, Cuts and bruises. 4 4 16 High Ensure good housekeeping workplace to clean shaves and dust. Always use hand gloves while handling pipes. Grinding to be done to prevent sharp edges before taking to installation. 1 4 4 Low

- 9. Saudi Constructioneers Ltd. Document Reference MC-SC-HSE-HIRA-079 Dated: 2023.02.12 OHSE Management System Page 9 of 9 9 | P a g e 10. Hydro-testing Release of uncontrolled energy. Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Property damage, time delays, financial loss, minor injuries, possibility of fatality. 5 5 25 High Ensure Hydro-Test-specific caution tapes and sufficient signages are placed around the perimeter of the area being tested. Ensure the correct exclusion zone is implemented as per the Hydro-Test calculations. Worker/inspection parties shall keep a safe distance away from all joints during pre-inspection, and inspection checks for leaks. Ensure gauges have a current calibration certificate and is correct for the task. Mechanical pump shall be manned at all times for the duration of the test. Both ground level and elevated level tasks involving electric-powered tools/ machineries etc. shall be moved away from the test area. Any temporary DB at location to be covered with plastic sheets during test. All works at height (in close proximity to lines being tested) are to be temporarily stopped once pressure gauge is in the 1bar range, until test is complete and the water is released, to prevent contact with pressured pipes Note – Hydro-testing: as a minimum should include the following precautions: A safe working distance to be established with regards to volume of the line (s) to be filled and the testing pressure. A stored energy (SE) calculation for the system should be prepared including piping-instrumentation and equipment included in the test. All persons involved in the Hydro testing will be fully conversant with all the requirements of the Method Statement. During the test, the exclusion zone will be barricaded off, and warning signs erected. Authorized personnel (wearing correct PPE) only to enter the test areas/exclusion zone. Warning alarm to be given before the test commences. Test schedules to be advertised on site notice boards. No other work allowed in the test areas. List of equipment and certifications to be produced. Emergency response arrangements must be in place. SC-OHSE-FOR-GEN-097 Hydro Pressure testing PTW to be implemented. 1 5 5 Low 11. De-watering Un controlled Release of water Saudico / Client / Supplier / Supervision / Skilled & Unskilled Labour Property damage, time delays, financial loss, minor injuries, possibility of fatality. 4 4 16 High Ensure pumping (pressuring machine) is turned off prior to de-watering. Do not release water directly from the mains valve. Insert a channeling hose to direct pressured water flow into the appropriate collecting tank/ditch etc. Hose shall be firmly secured to prevent it from flailing. Valve shall be cracked open gradually to release water. If ditch is been used to collect and dispose water, ensure they are dug laterally away from any existing underground cables/utilities. Test shall not be considered as completed nor the area cleared for other works until all pressured lines has been de-pressurized and de-watered. 1 4 4 Low Std PPE: Hard Hat, Safety Glasses, High Vis Vest, Coverall, Steel- cap Safety Shoes. Additional PPE: Apron, welding shield, face shield, ear defenders, ear plug.