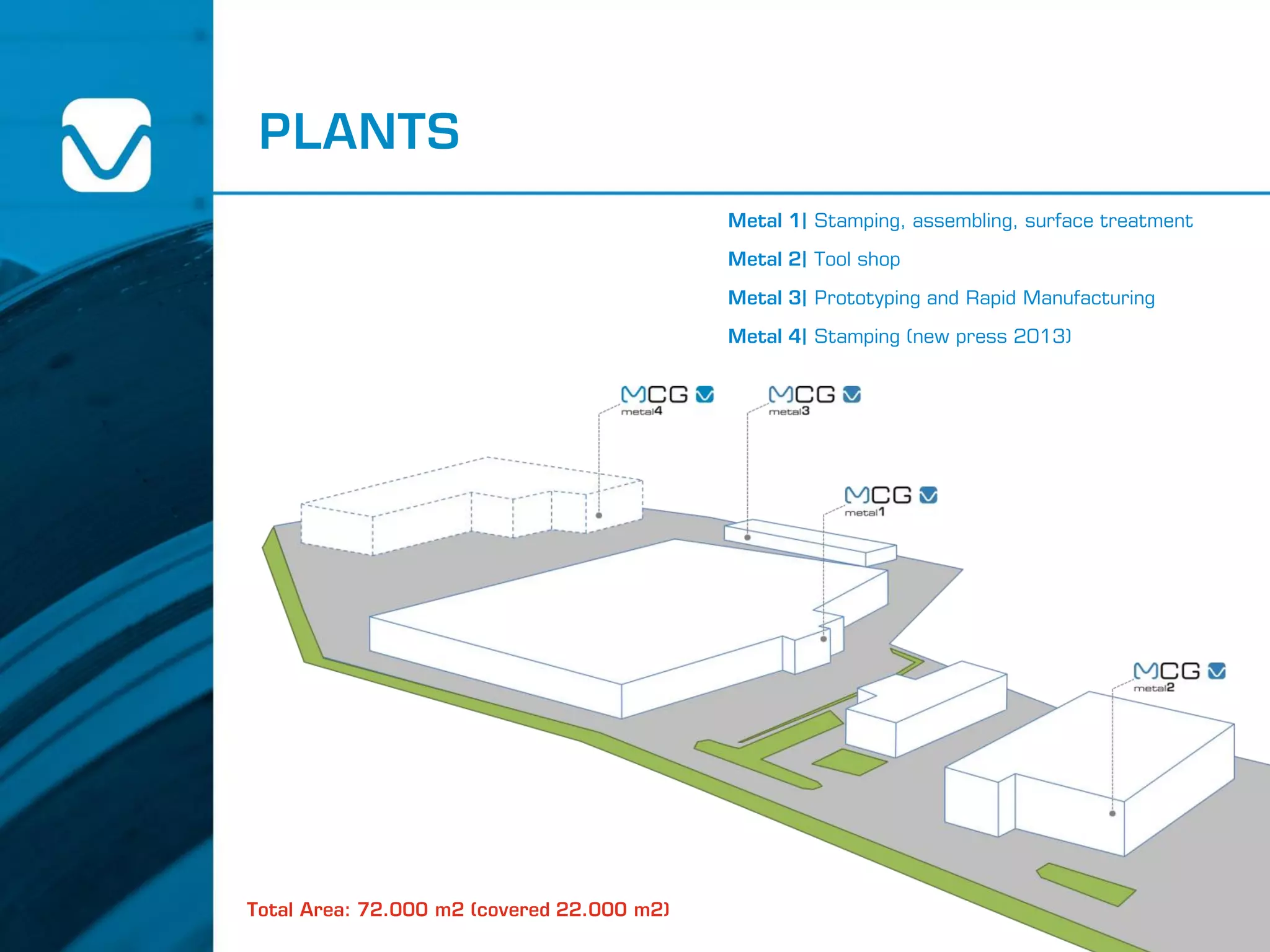

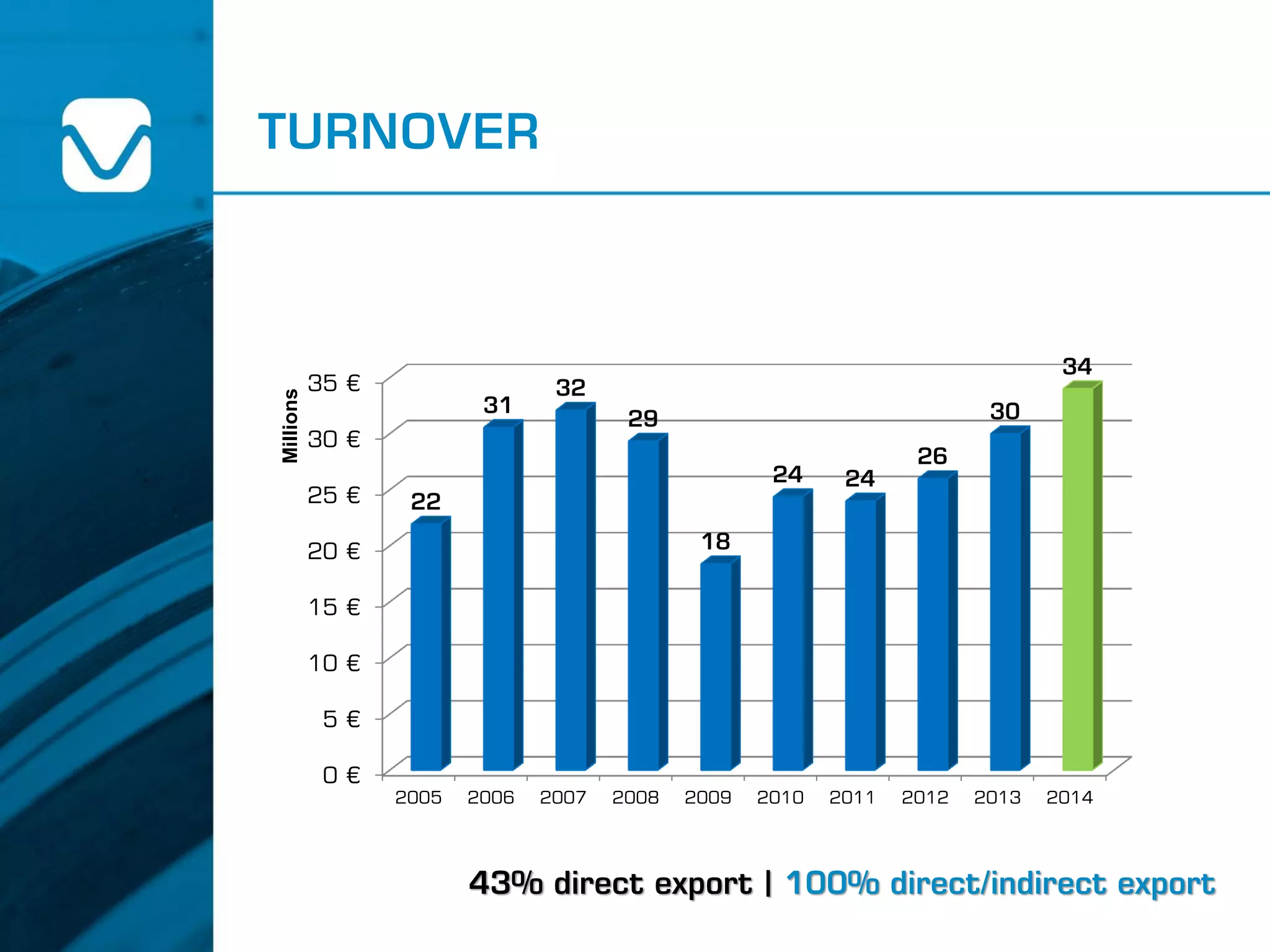

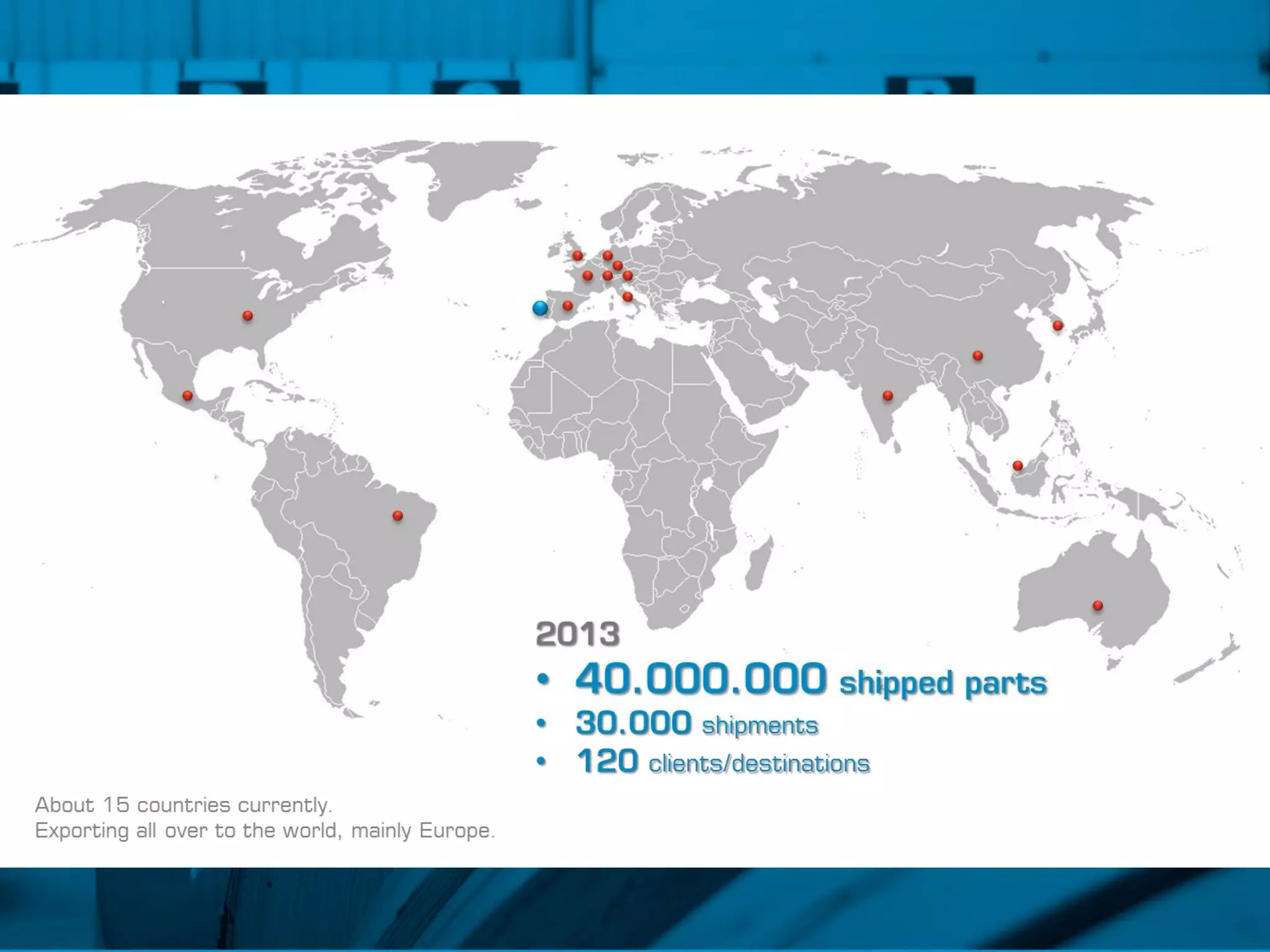

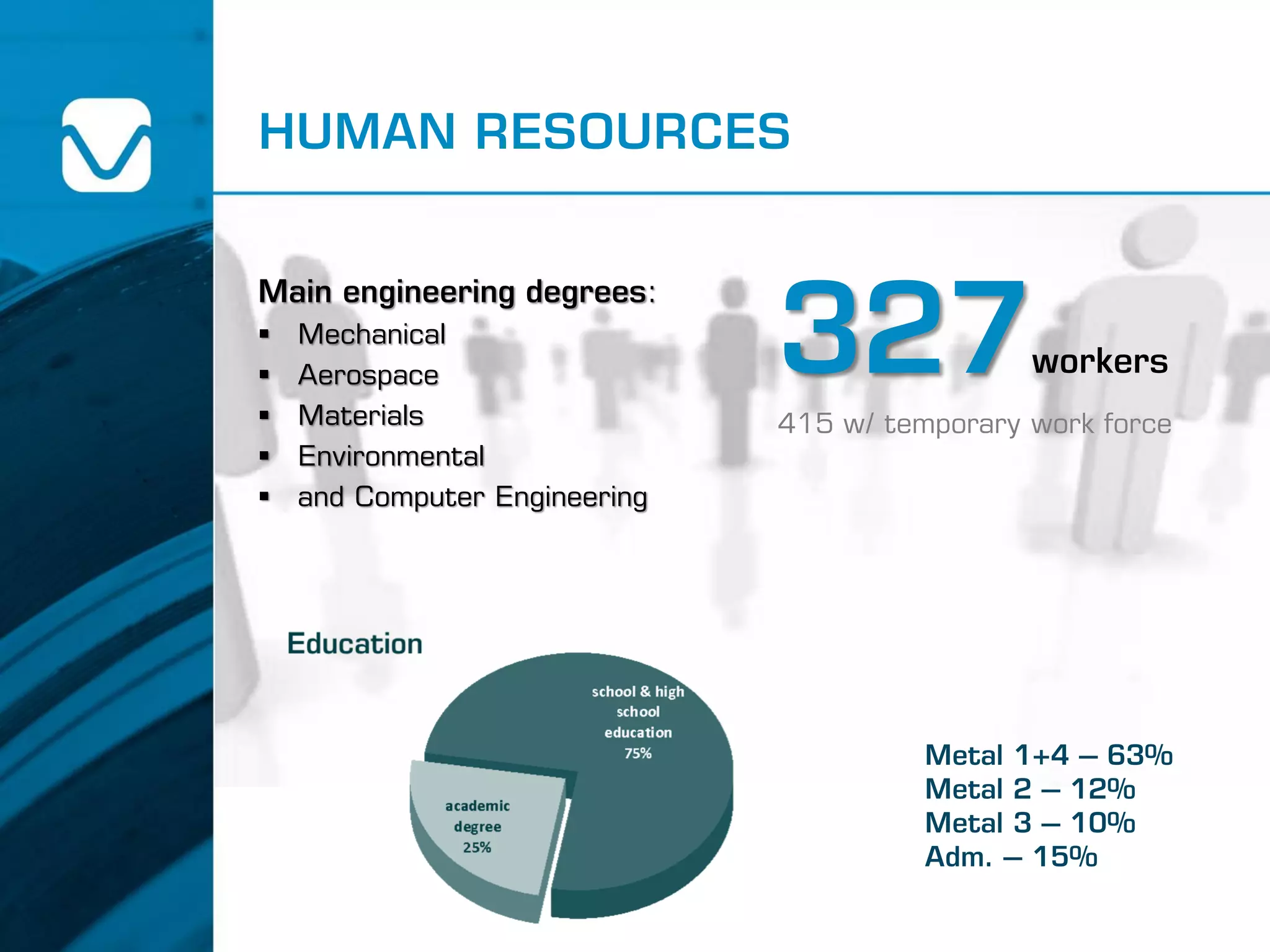

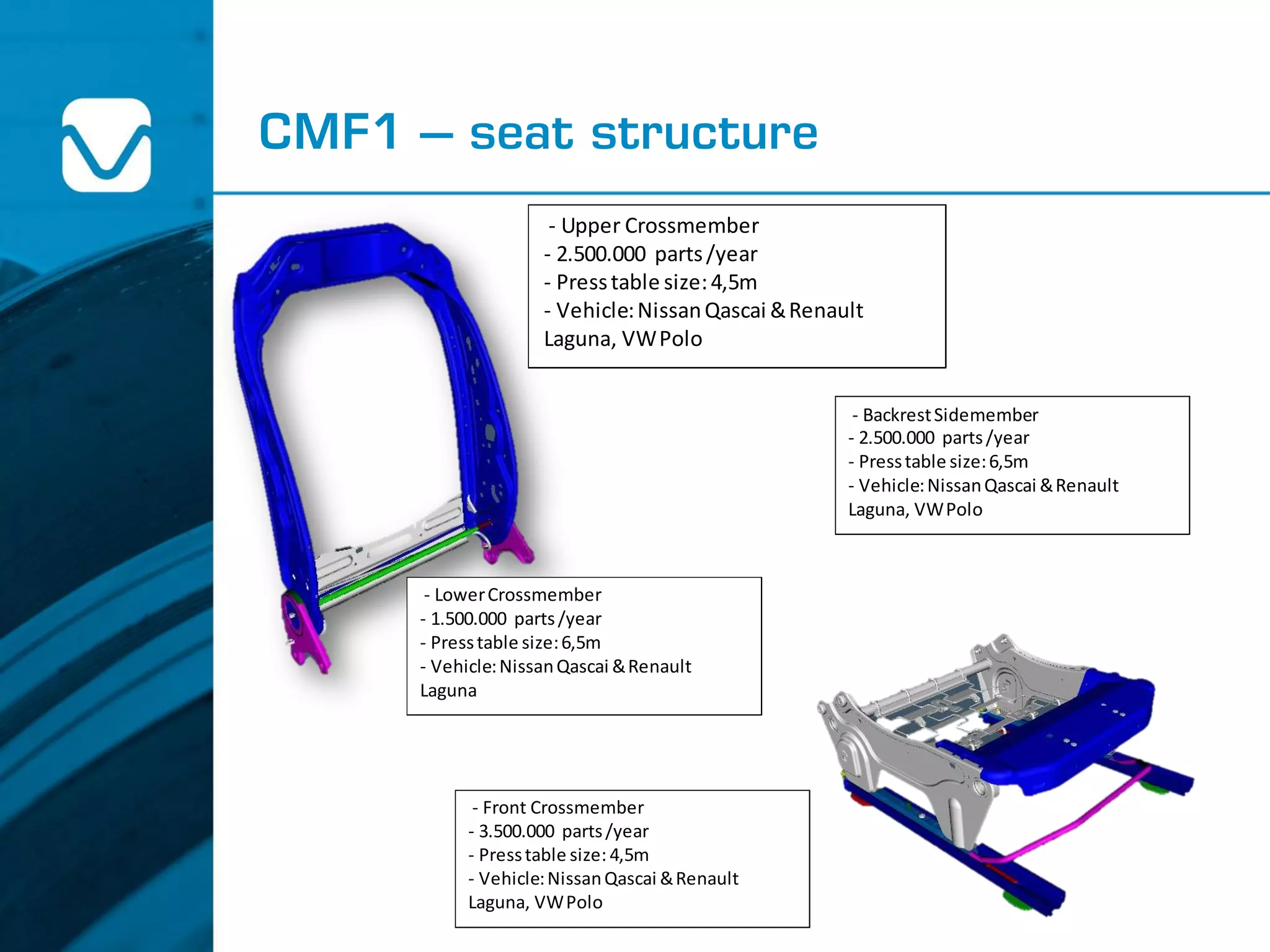

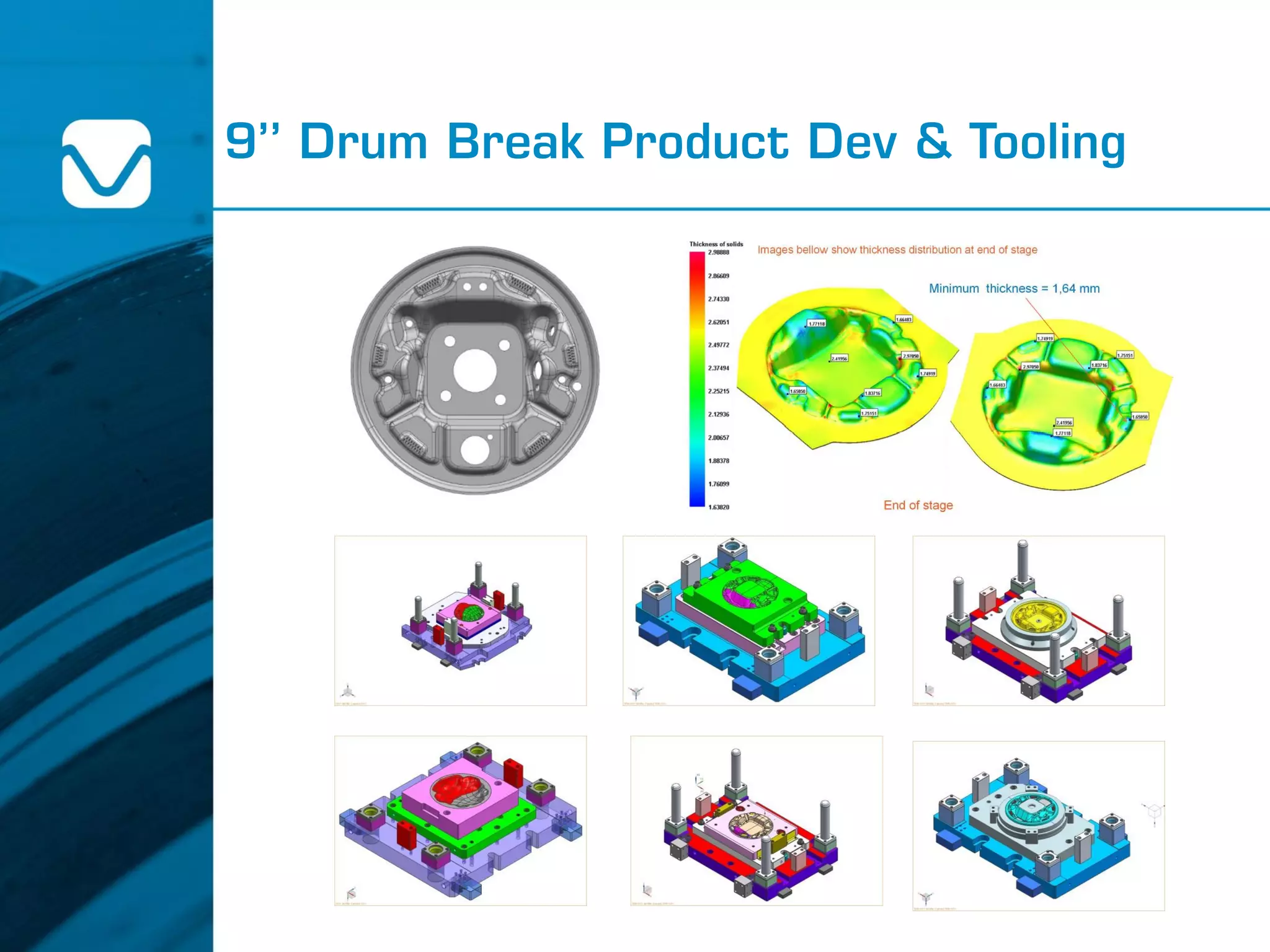

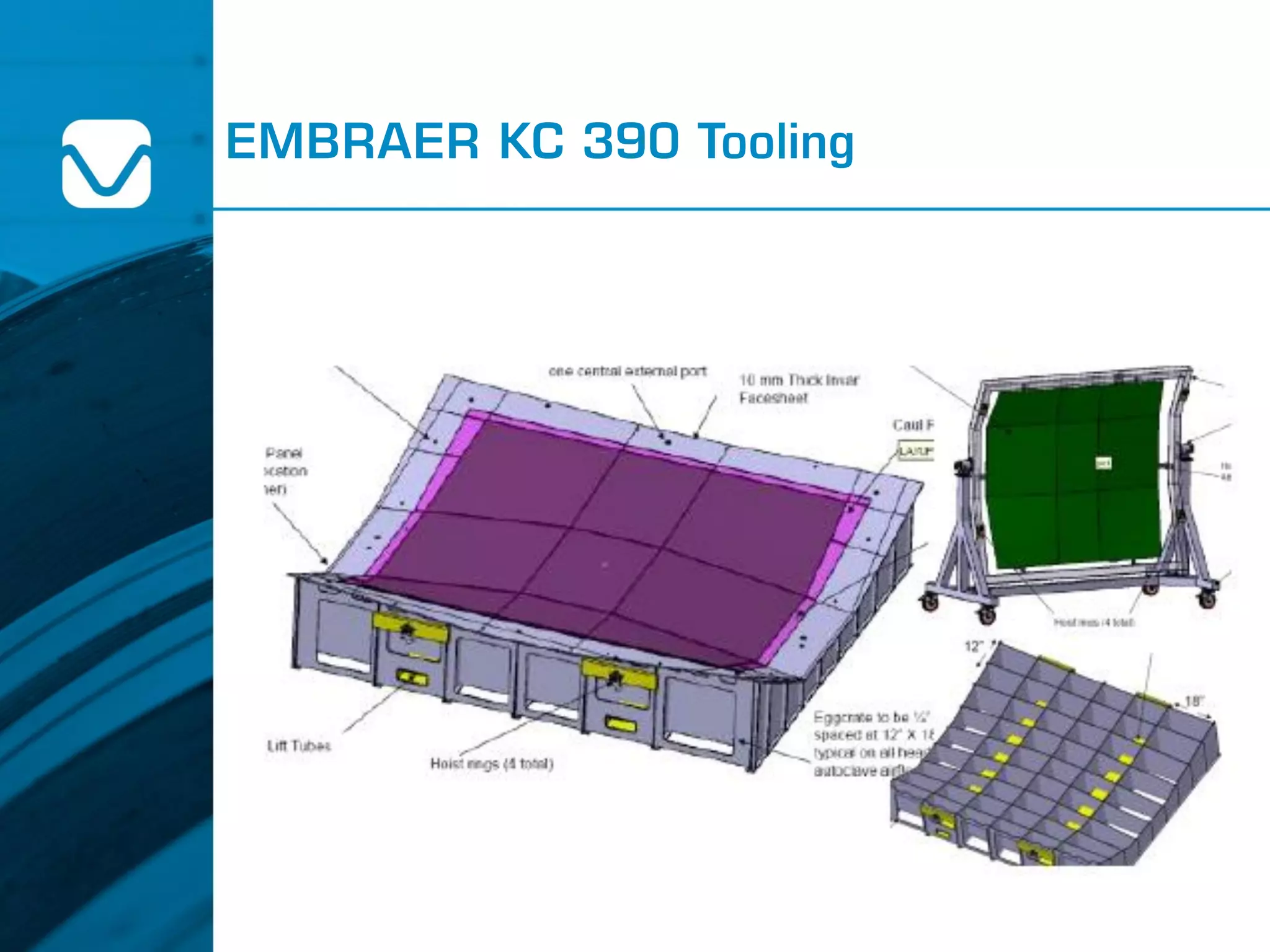

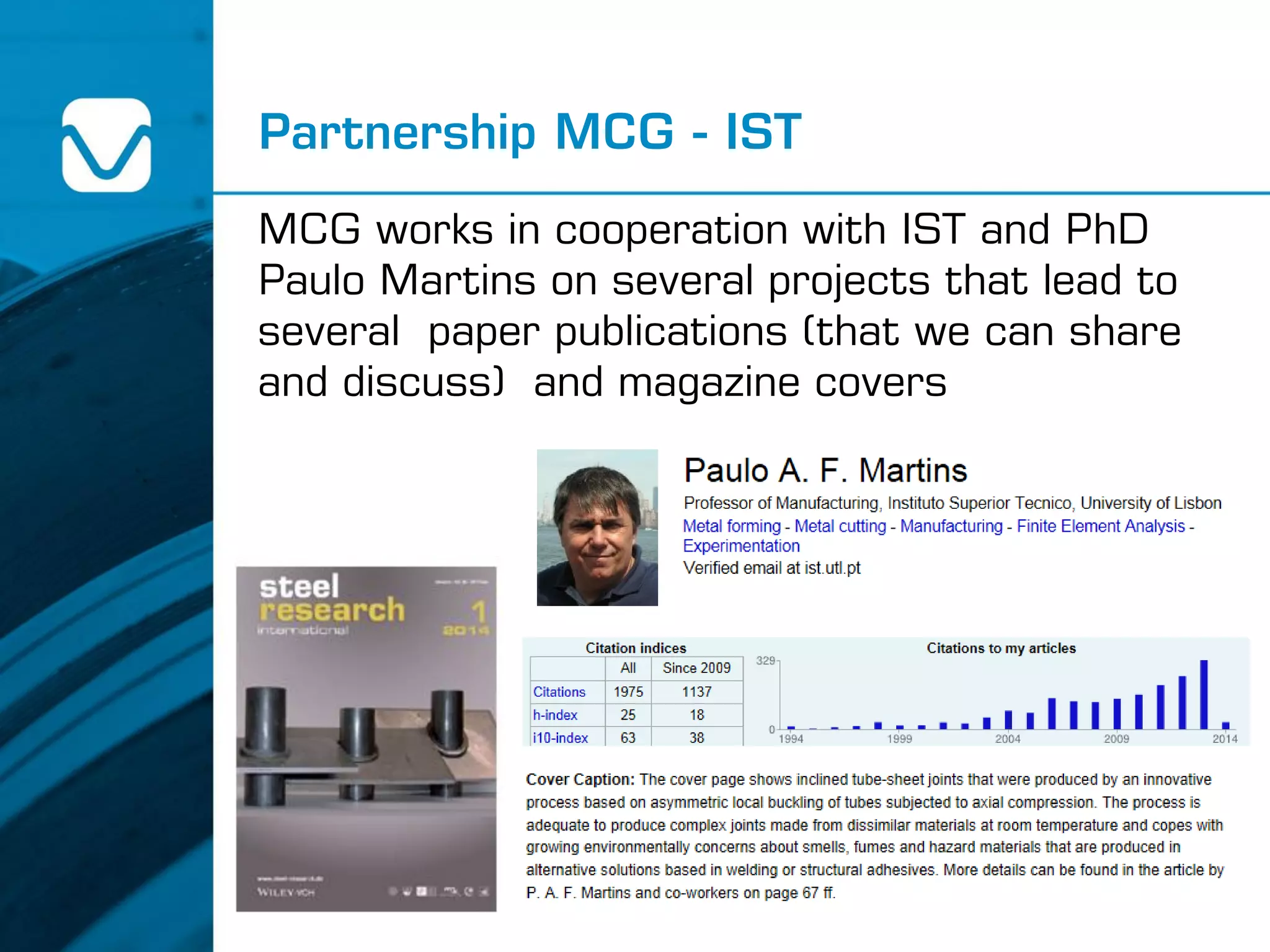

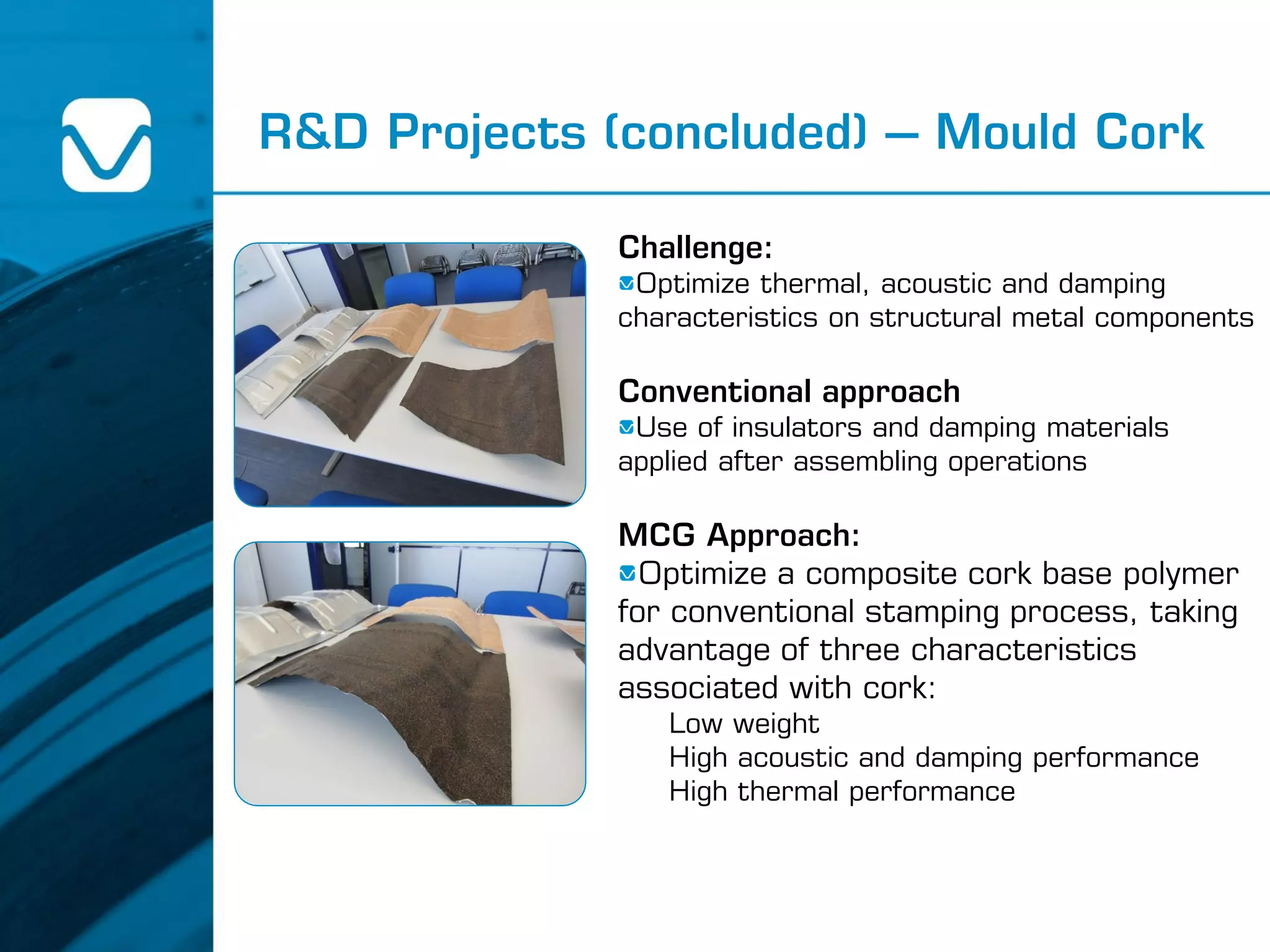

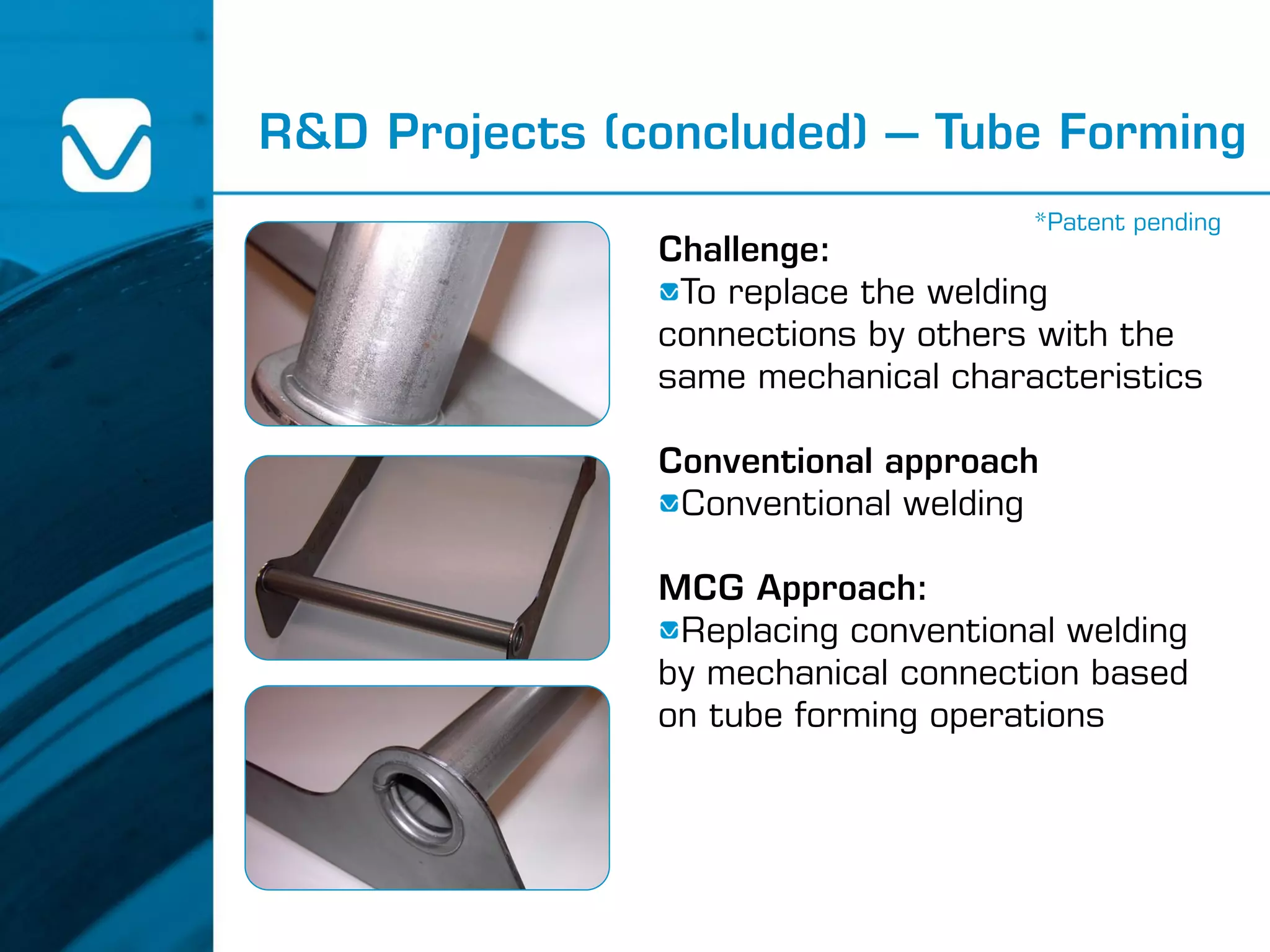

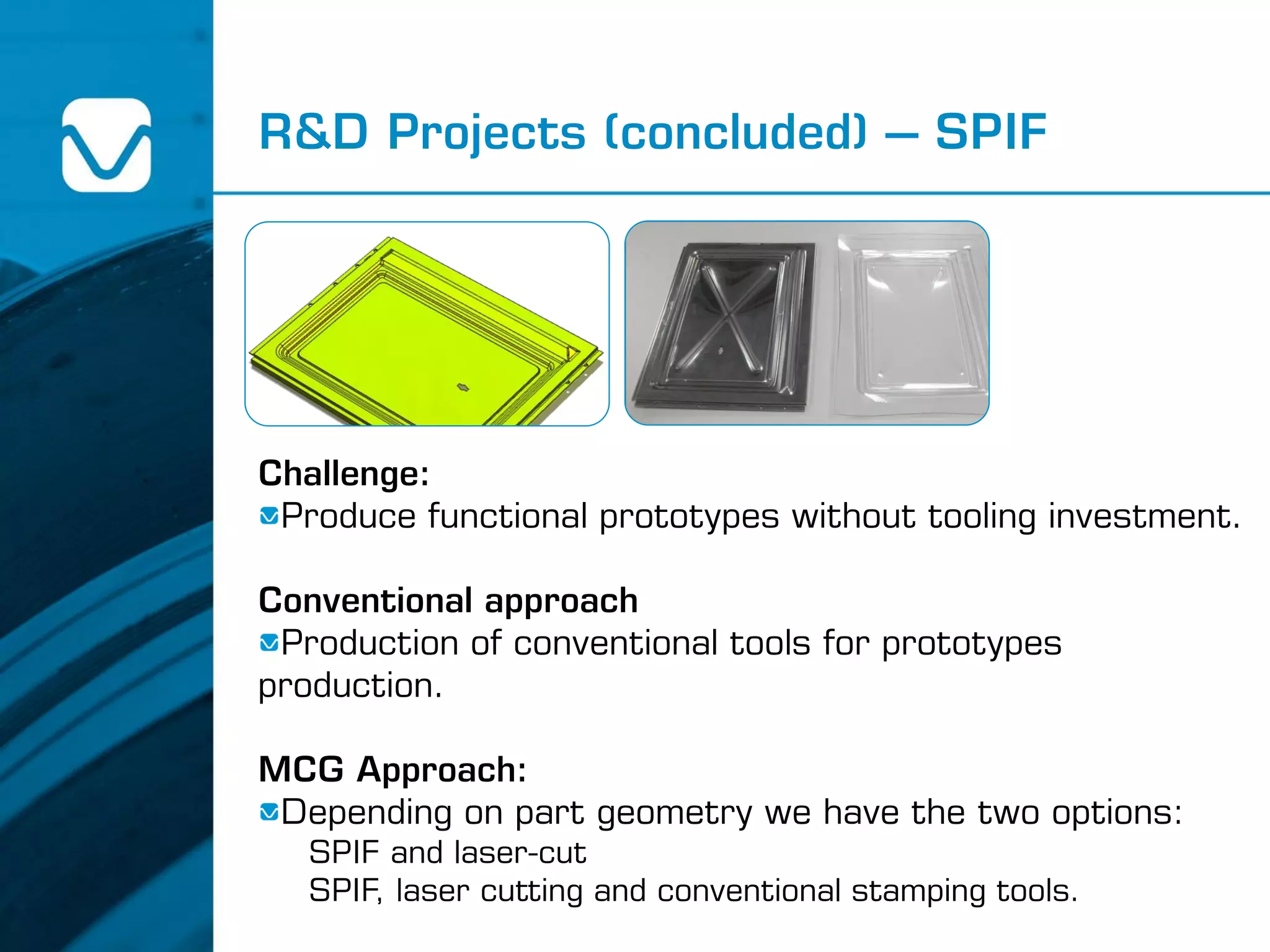

MCG is a family-owned private company located in Portugal that was founded in 1978. It has four business units and produces metal components, tooling and dies for the automotive, solar, and other industries. Over the decades, MCG has expanded its facilities and invested in new technology and management systems. It currently has four plants across 72,000 square meters and 327 employees. MCG partners with universities on research projects and has invested in new equipment like a laser cutting machine and simulation software to support its operations.