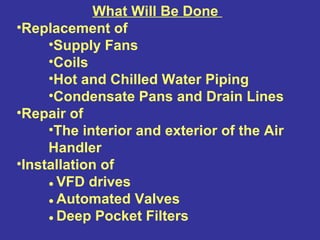

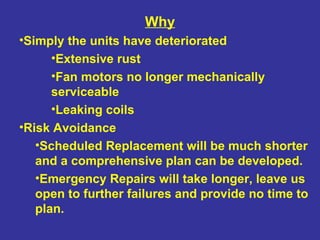

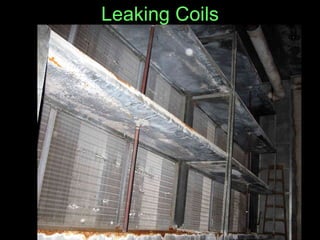

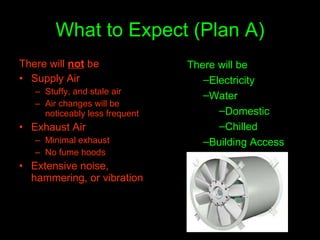

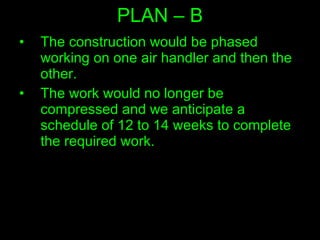

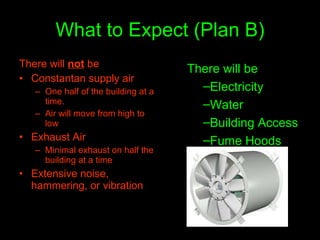

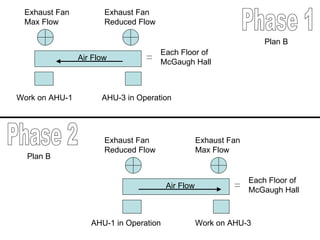

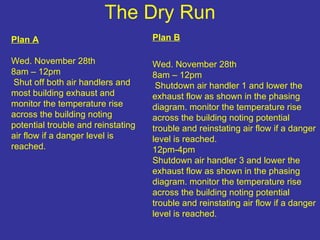

The document summarizes plans for replacing air handlers in McGaugh Hall at UCI. Plan A would completely shut down the building during construction, compressing work into the shortest time. Plan B would phase construction over 12-14 weeks, working on one air handler at a time to minimize disruptions. Both plans address contingencies like temporary cooling and freezer storage if needed during the work. A dry run of each plan is scheduled for November 28th to test temperature rise in parts of the building with reduced airflow.