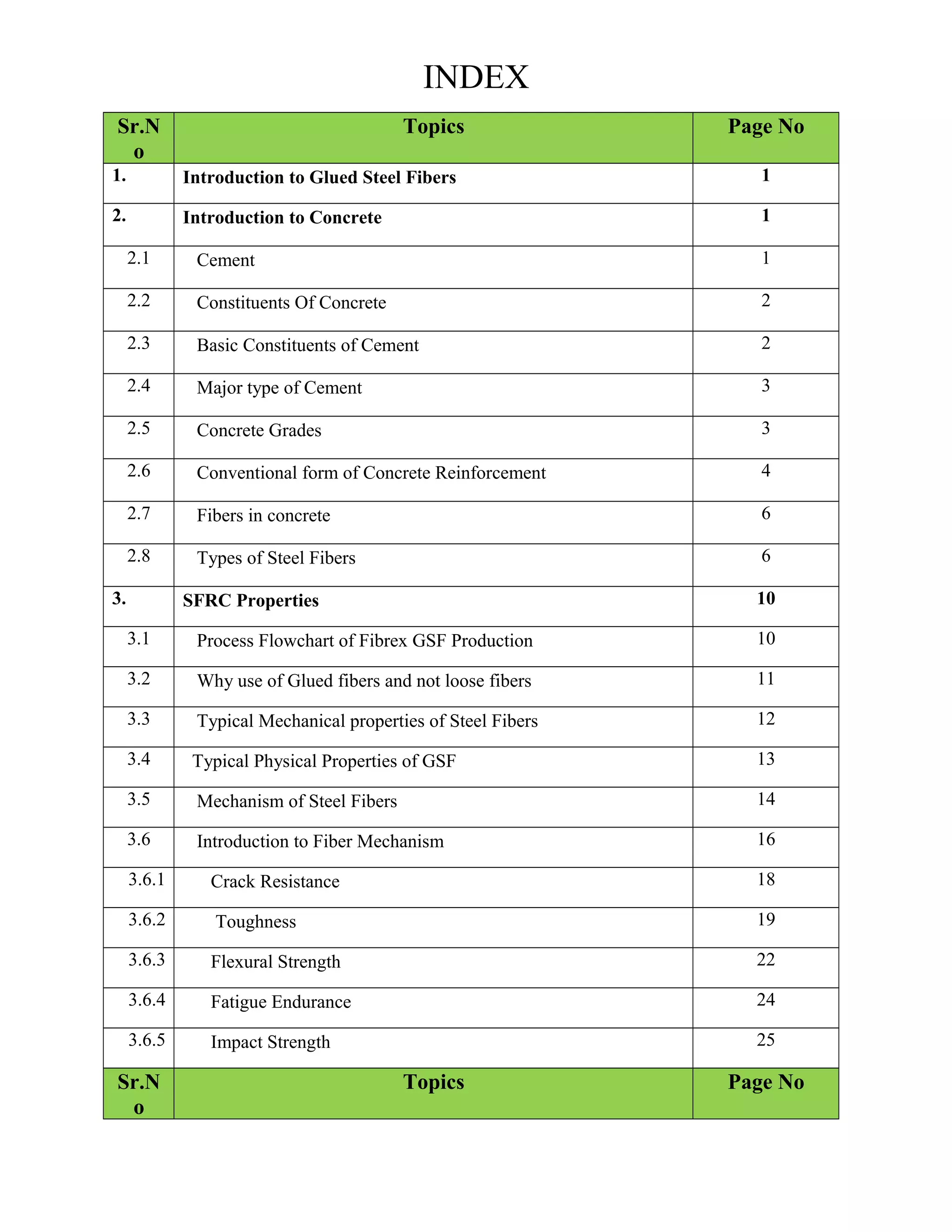

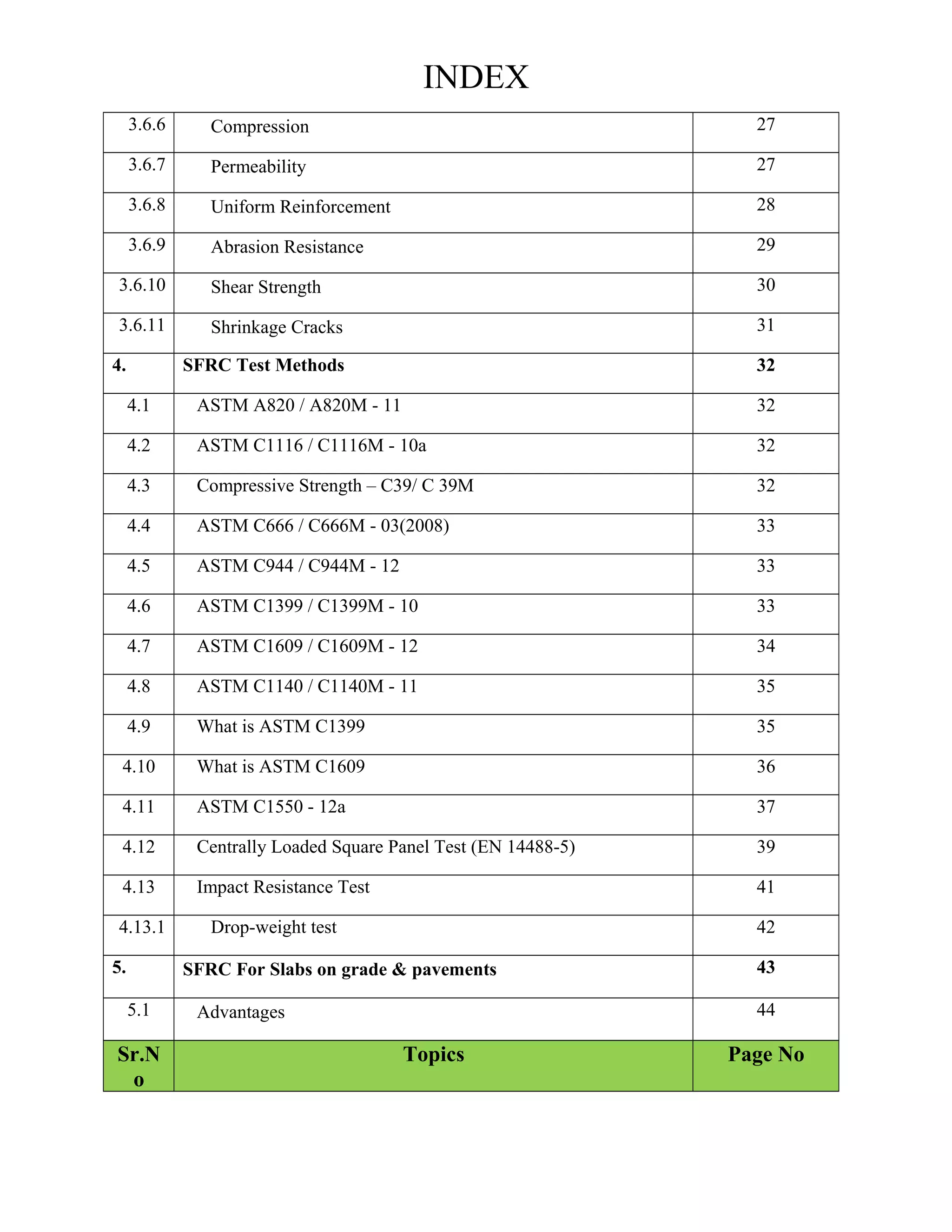

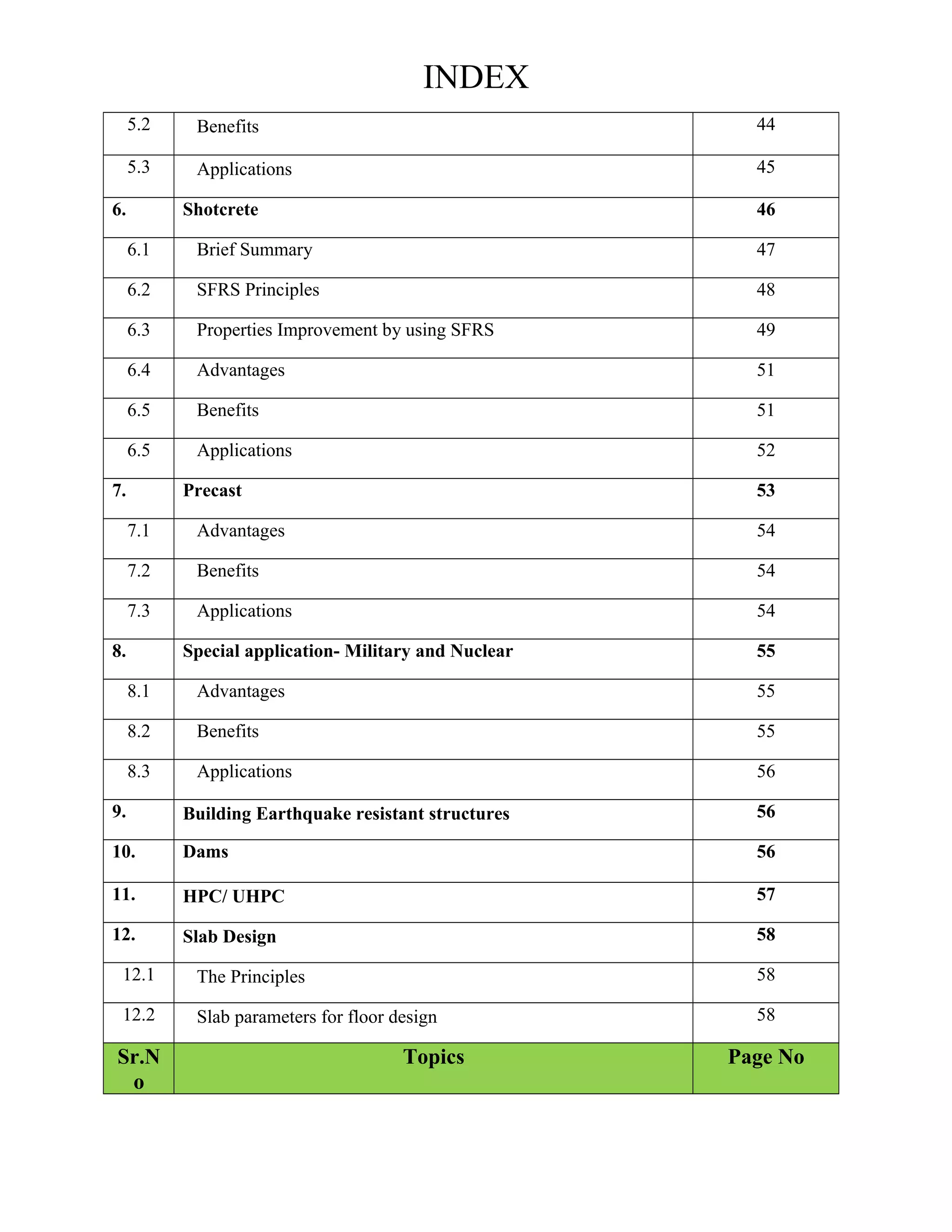

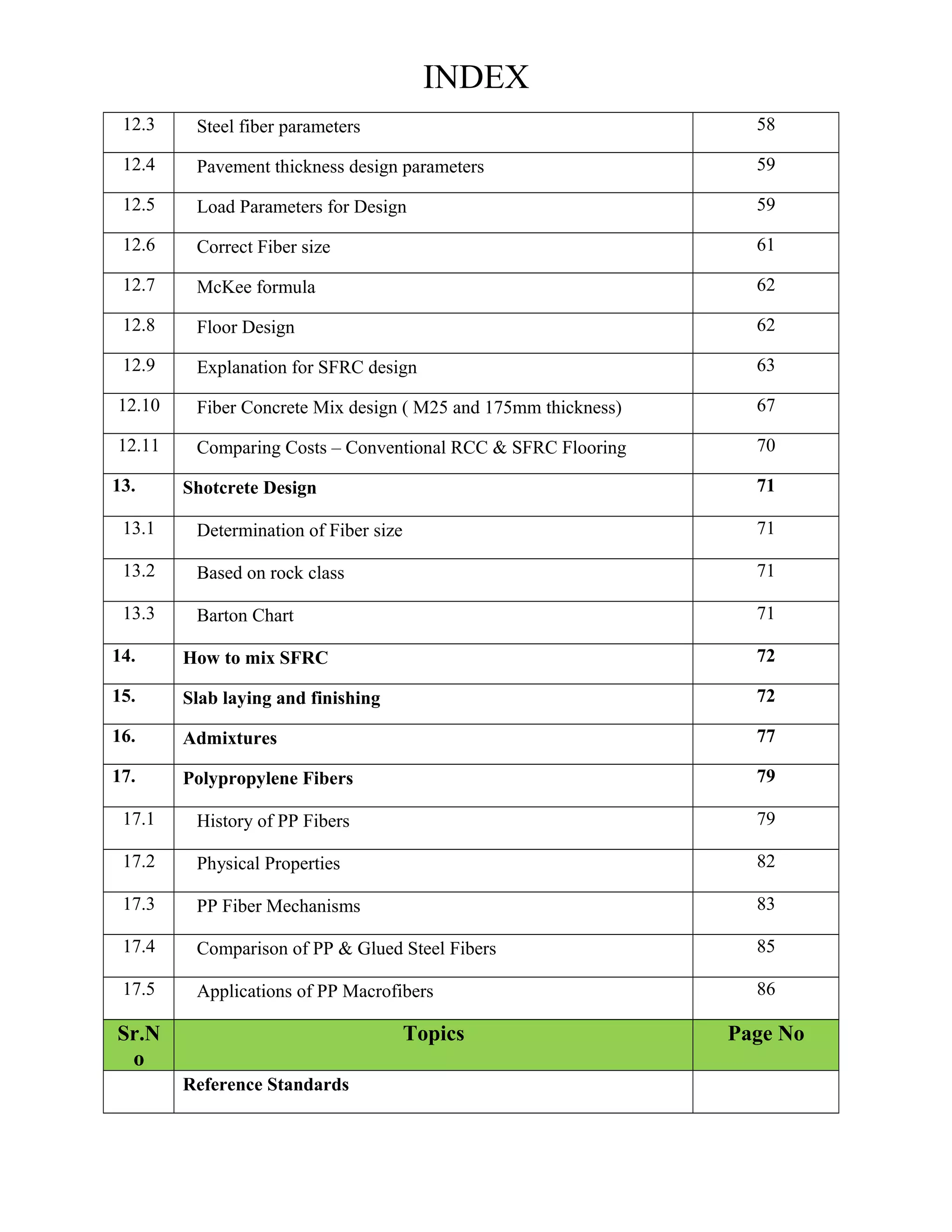

This document provides an index of topics related to glued steel fibers in concrete. It discusses the properties and benefits of steel fiber reinforced concrete (SFRC), including increased crack resistance, toughness, flexural strength, fatigue endurance, impact strength, compression strength, permeability, uniform reinforcement, abrasion resistance, shear strength, and reduced shrinkage cracks. It also outlines various test methods for SFRC like ASTM A820, ASTM C1116, compressive strength testing, and more. Application areas covered include slabs on grade, pavements, shotcrete, precast concrete, military/nuclear structures, dams, high performance concrete, and slab and shotcrete design. The document also briefly discusses polypropy