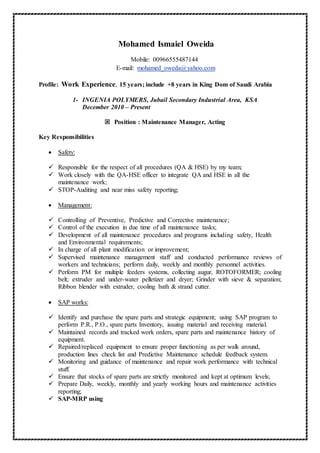

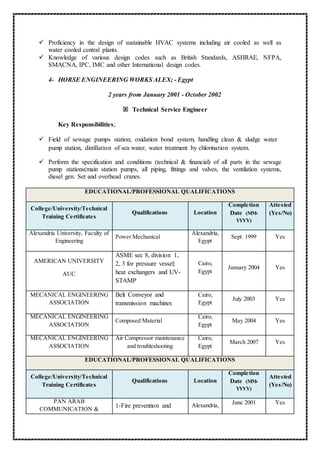

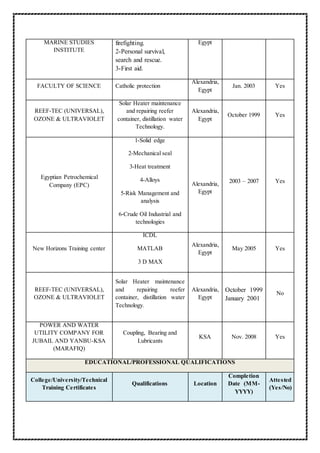

Mohamed Ismaiel Oweida has over 15 years of work experience, including more than 8 years in Saudi Arabia. He currently works as the Acting Maintenance Manager at Ingenia Polymers in Jubail, Saudi Arabia, where he is responsible for safety management, maintenance management, SAP systems, and developing local suppliers. Previously, he held engineering roles in Saudi Arabia and Egypt, including senior design engineer roles focusing on pressure vessels, heat exchangers, and tanks. He has a bachelor's degree in power mechanical engineering and various technical certifications.