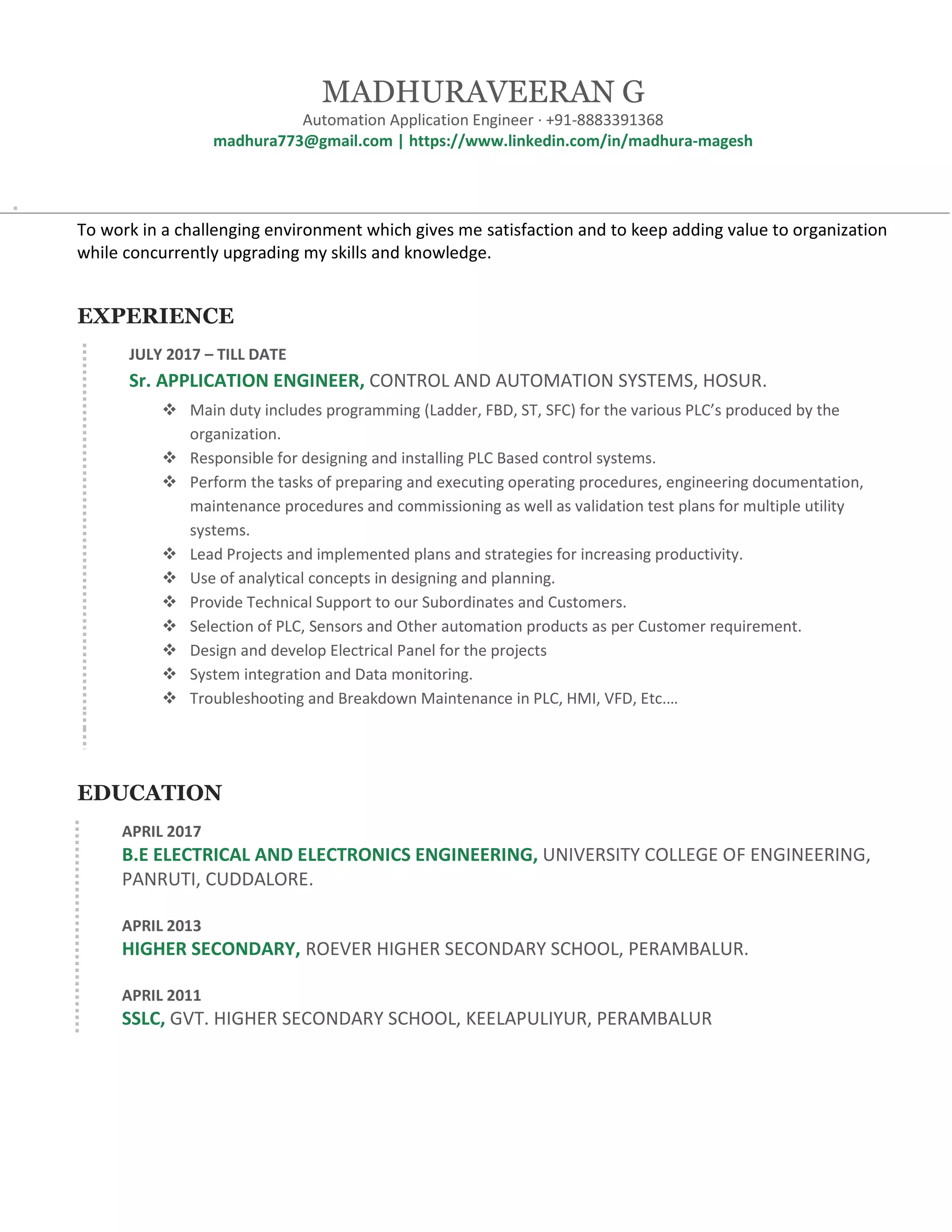

Madhura is an automation application engineer with over 4 years of experience programming PLCs and designing control systems. He has a Bachelor's degree in electrical and electronics engineering. His skills include programming PLCs from various manufacturers in ladder logic, function block, and structured text. He also programs HMIs and has experience with SCADA systems. Some of his projects include designing control systems for a high speed press feeder machine, a seat belt buckle inspection machine, and commissioning automation on multiple production lines.

![2

SKILLS

PLC Programming

Ladder Logic

Function Block Definition [FBD]

Structured Text [ST]

IEC 61131-3 PLC Open Programming

HMI & SCADA Programming

Vision System Configuring

Omron FQ2 Series Vision Systems

Keyence IV Navigator Series Vision Systems

System Integration Protocols

RS 232

RS 485/422

Modbus serial and TCP/IP

Hostlink

Ethernet/IP

EtherCAT

OPC

IIoT-MQTT

Safety Device Configuring

Safety Light Curtain

Safety Scanner

Safety Pull Cord Switch

CORE SKILLS

PLC PROGRAMMING SKILLS

Omron CX-One Software V4.40

Omron Sysmac Studio 1.20

Omron Zen Support Software V4.1

Mitsubishi GX Developer 8.0

Mitsubishi GX Works2 V1.91

Siemens TIA Portal V13.0

Siemens Logo 8.2

Connected Components Work Bench V11

Automation Builder 2.0

Delta WPL Soft V2.46

FIELD OF INTEREST

Process Automation

System Integration

Industrial Internet of Things (IIoT)

Drives and Control

Robotics Automation

IIoT Skills & Data Analysis and Visualization

Raspberry Pi

Node-Red

Node-Red Dashboard Visualization

MS SQL Server

Local/Online MQTT Broker Configuration

VFD & Servo Configuring

Omron 3G3MX2 Series

Mitsubishi FR-D700 Series

ABB ACS Series

Yaskawa V1000, A1000 Series

Delta VFD-L Series

Omron R88D-KN, R88D-1SN,R88M-KE Series

Servo Drives

Mitsubishi MELSERVO MR-JE Series

Industrial Automation Product Skills

Temperature Controller

Programmable Relays

Timers

Counters

Power Monitoring Relays

Fiber Sensor Units

Profile Measurement Sensors

HMI PROGRAMMING SKILLS

Omron NB Designer V1.44

Omron CX-Designer V3.6

Proface GP-ProEx V4.08

Delta DOPSoft V2.00

Mitsubishi GOT Designer3 V1.13

Weintek Easy Builder Pro V6.01.01.273

SCADA PROGRAMMING SKILLS

Siemens WinCC Advanced V15.1

Wonderware Intouch V17.1](https://image.slidesharecdn.com/madhuraveerang-automationapplicationengineer-200218041746/85/Madhuraveeran-g-automation-application-engineer-2-320.jpg)

![5

TRAINING

Undergone Industrial ‘Robotic Training’ Conducted by Omron at Bangalore

Undergone Modular PLC & HMI Training Conducted by Omron at Bangalore

Undergone Advanced Controller’s ‘PLC Open Programming’ Technology Training Conducted by Omron at

Bangalore

Undergone ‘Industrial Machine Safety’ Training Conducted by Omron at Bangalore.

Successfully Completed Master Diploma in ‘Industrial Automation and Control Systems’ at Winpro Automation,

Pondicherry.

Successfully Completed Professional Training on ‘Computer Hardware’s and Networking Technology’ at NIIT,

Villupuram.

PERSONAL DETAILS

Father’s Name : Mr. Gandhi L

Mother’s Name : Mrs. Sellamal G

Date Of Birth : 13 April 1996

Sex : Male

Marital Status : Single

Nationality : Indian

Language Known : English, Tamil, Kannada, Telugu

Current Location : Bangalore

PASSPORT DETAILS

Passport No. : U1125568

Date of Issue : 25/11/2019

Date of Expiry : 25/11/2029

Place of Issue : Tiruchirapalli

ADDRESS FOR COMMUNICATION

No.3/252, Anna Nagar,

Sengunam,

Perambalur,

Tamil Nadu,

India.

PIN: 621220

DECLARATION

I hereby declare that the above particulars given are true and faith to the best of my knowledge and belief.

DATE : Yours Sincerely

PLACE :

[MADHURAVEERAN GANDHI]](https://image.slidesharecdn.com/madhuraveerang-automationapplicationengineer-200218041746/85/Madhuraveeran-g-automation-application-engineer-5-320.jpg)