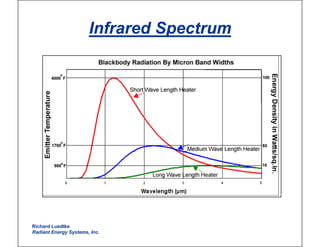

This document summarizes Richard Luedtke's presentation on basic industrial drying fundamentals and methods. The presentation covered defining process requirements, conventional drying methods including convection, impingement, floatation, and through air drying. It also discussed understanding the drying/heating process, equipment selection considerations, and provided an overview of infrared drying advantages and limitations. The key takeaway is that the best drying method for a given application is often a combination of technologies tailored to the specific product and process requirements.