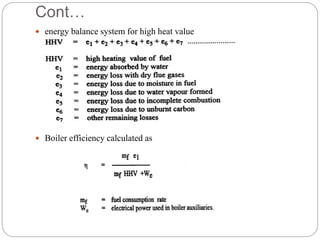

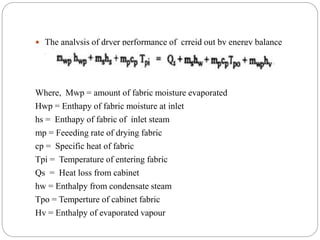

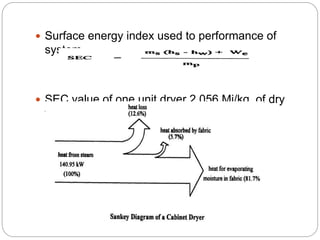

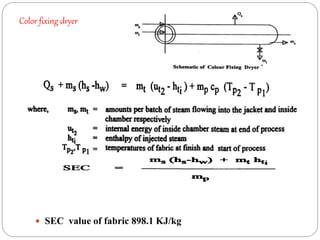

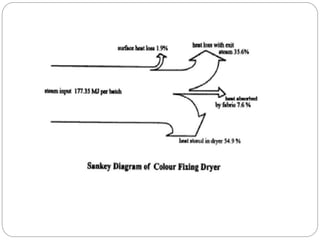

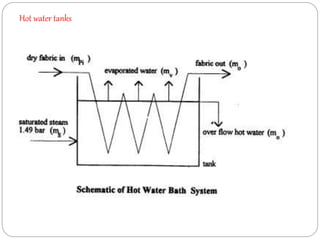

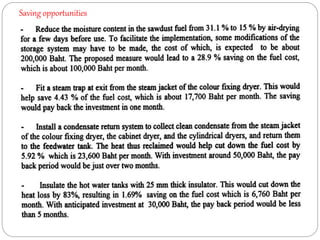

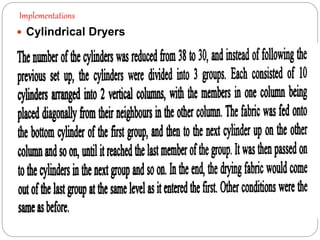

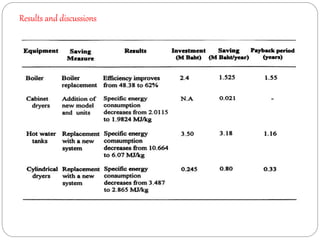

This paper reports on an energy conservation study conducted at a textile printing factory. The study analyzed five energy-consuming processes: boilers, cabinet dryers, color fixing dryers, hot water tanks, and cylindrical dryers. The analysis found several opportunities to improve energy efficiency, such as improving boiler insulation and installing variable speed drives. Four recommendations were implemented, resulting in estimated annual energy savings of 5.426 million Baht and a 30% reduction in process-specific energy consumption. The study demonstrates that textile factories can significantly improve their energy utilization.