This document summarizes an article from the May 2015 issue of Inbound Logistics magazine. The article discusses how changes in technology, e-commerce, and consumer demand are transforming today's warehouses. It explores how cloud computing, omnichannel management, and last-mile logistics are reshaping warehouse facilities and operations. It also looks at how warehouse managers are transforming their workforces to include people from diverse backgrounds to meet these new challenges.

![INFOCUS GLOBALTHE WORLD AT A GLANCE

moving forward with the new regulation—

a policy change that it believes will raise

the quality and reliability of the country’s

logistics sector. Companies will be given

three years to comply. The regulation is

currently with the Law and Human Rights

Ministry for further assessment.

Even with such a grace period for com-

pliance, ALFI argues that most companies

won’t be able to meet that requirement.

Instead it has suggested that the govern-

ment should classify logistics companies

by size rather than applying one set of reg-

ulations across the entire industry.

U.S. Japan

Near TPPing

Point

The United States and Japan are still

at loggerheads over automobile and agri-

culture export terms, which is delaying

progress toward reaching a landmark Trans

Pacific Partnership (TPP). But both sides

indicate a deal is within reach, according

to a recent Associated Press report.

The talks between Japan and the United

States are part of negotiations among 12

nations participating in the U.S.-led Trans

Pacific Partnership. The goal of the part-

nership is to create a free trade zone in the

Asia-Pacific region.

A hangup over increased exports of

U.S. rice to Japan, and Japanese auto-

mobiles and auto parts to the United

States, appears to be nearing a resolution,

although negotiations continue.

In April 2015, U.S. lawmakers proposed

new legislation that would allow President

Barack Obama to negotiate trade accords

for overall congressional review. This is

helping to push forward negotiations, the

Associated Press reports.

Japan’s protectionist policies have long

favored agricultural products—nota-

bly rice. The country’s aging population

and changing tastes have contributed to

less rice consumption, which has created

a surplus. [ ]

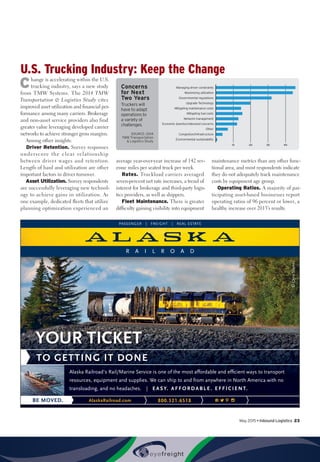

Global Container Trade

Floats on Optimism

An uptick in ocean trade suggests that the global economy is showing

positive and sustainable signs of recovery. But an enduring capacity

imbalance still threatens steamship line profitability.

Demand for container shipping is expected to grow upwards of five percent

in 2015, even as freight rates continue to decline due to a surplus of capacity,

according to Lars Mikael Jensen, chief executive of Maersk Line’s Asia Pacific

region. As ships ordered several years ago are just now coming online, supply

growth is anticipated at five to seven percent.

The average revenue per TEU is dropping as rates vary in different trades,

which is attributed to supply-demand imbalance. This places additional

pressure on shipping lines to reduce costs on a per-box basis.

“We are working in a scenario where there won’t be a massive upward

return of the average revenue per box, so cost savings and efficiencies are

important,” says Jensen.

The recent financial results of most steamship lines suggest revenues and

profit margins are under pressure, he adds, especially those generated from

the east-west trades.

Maersk needs to invest in new ships to keep up with global growth, and to replace

older ships that are coming to the end of their efficient life span, notes Lars Mikael

Jensen, chief executive of Maersk Line’s Asia Pacific region.

28 Inbound Logistics • May 2015](https://image.slidesharecdn.com/ildigitalmay2015-150612230643-lva1-app6891/85/Logistics-and-supply-chain-May-2015-32-320.jpg)

![52 Inbound Logistics • May 2015

[the technology-based language learning

program], so we can train some of our

good leaders and supervisors in Spanish,”

Johnson says.

An English-speaking supervisor doesn’t

need to fully master a second language

to improve communications. Eck recalls

his early days as a warehouse manager,

when his staff included 20 to 30 Spanish-

speaking associates. “I learned how to ask

them if they needed more water, if they

needed to use the restroom, if they were

doing okay—just so I could walk around

and let them know I was concerned for

their well being,” he says. When the time

came to hold a more complex conversation,

he tapped a bilingual worker to translate.

Of course, in a polyglot warehouse—

a place where, say, Spanish, Russian, and

two Chinese dialects fill the air—commu-

nications grow even more complicated.

One of Sardeson’s clients met that chal-

lenge by putting all the associates who

spoke the same language on the same

team. “It created an environment where,

with one supervisor leading a team of 12,

they weren’t embarrassed to ask questions,”

Sardeson says. Everyone could take care of

business in his or her native tongue.

Does that strategy promote segregation

or discrimination? Not at all, Sardeson

says. “They’re putting people in a situation

where they can win,” he notes. “I thought

it was bold of them to break them up that

way, and it was much more effective.”

A different set of solutions applies to

the literacy challenge. From instructional

materials, to signage in the building, to

read-outs on handheld scanners, ware-

house managers look for ways to convey

important information to workers who

don’t read English well, or can’t read at all.

When not everyone reads the same lan-

guage, a WMS that issues picking and

putaway instructions on a printed list, or

through a readout on a handheld radio

frequency (RF) scanner, presents a tough

challenge. “It becomes cost prohibitive to

maintain several languages for paper and

RF processes,” says Bruce Stubbs, industry

marketing director at Honeywell Scanning

and Mobility.

THE LANGUAGE OF LOGISTICS

The challenge is even tougher when

managing associates who lack reading skills

in any language.

Some warehouses level the playing field

for workers by implementing voice-directed

picking and putaway solutions. Instead of

requiring a worker to read from a screen or

printout, these systems speak directions in

English or another language. The associ-

ate also can confirm completed activities

by speaking into the system.

“The user simply trains the voice data-

base in the language they feel comfortable

using,” says Stubbs, whose company’s

products include the Vocollect family of

voice-based warehouse solutions. “Voice is

smart enough to also allow for dialect dif-

ferences, and the different ways that people

speaking the same language pronounce

certain words.”

Vocollect supports more than 35 lan-

guages, says Jay Blinderman, director

of product marketing for Honeywell’s

Vocollect Solutions, headquartered in

Pittsburgh. It’s even possible to mix and

match languages to some extent. “For

example, if workers understand English

but are more comfortable speaking in

Spanish, the system might direct them to

pick three units, and the workers may con-

firm by saying ‘tres,’” Blinderman says.

Intelligrated, a vendor of materials han-

dling solutions based in Mason, Ohio,

offers a voice-directed picking solution

that operates in approximately 65 lan-

guages and requires no training. “Users put

Technology such as voice-directed picking or putaway systems facilitate communication

with warehouse workers who lack reading skills or may not speak English.](https://image.slidesharecdn.com/ildigitalmay2015-150612230643-lva1-app6891/85/Logistics-and-supply-chain-May-2015-56-320.jpg)