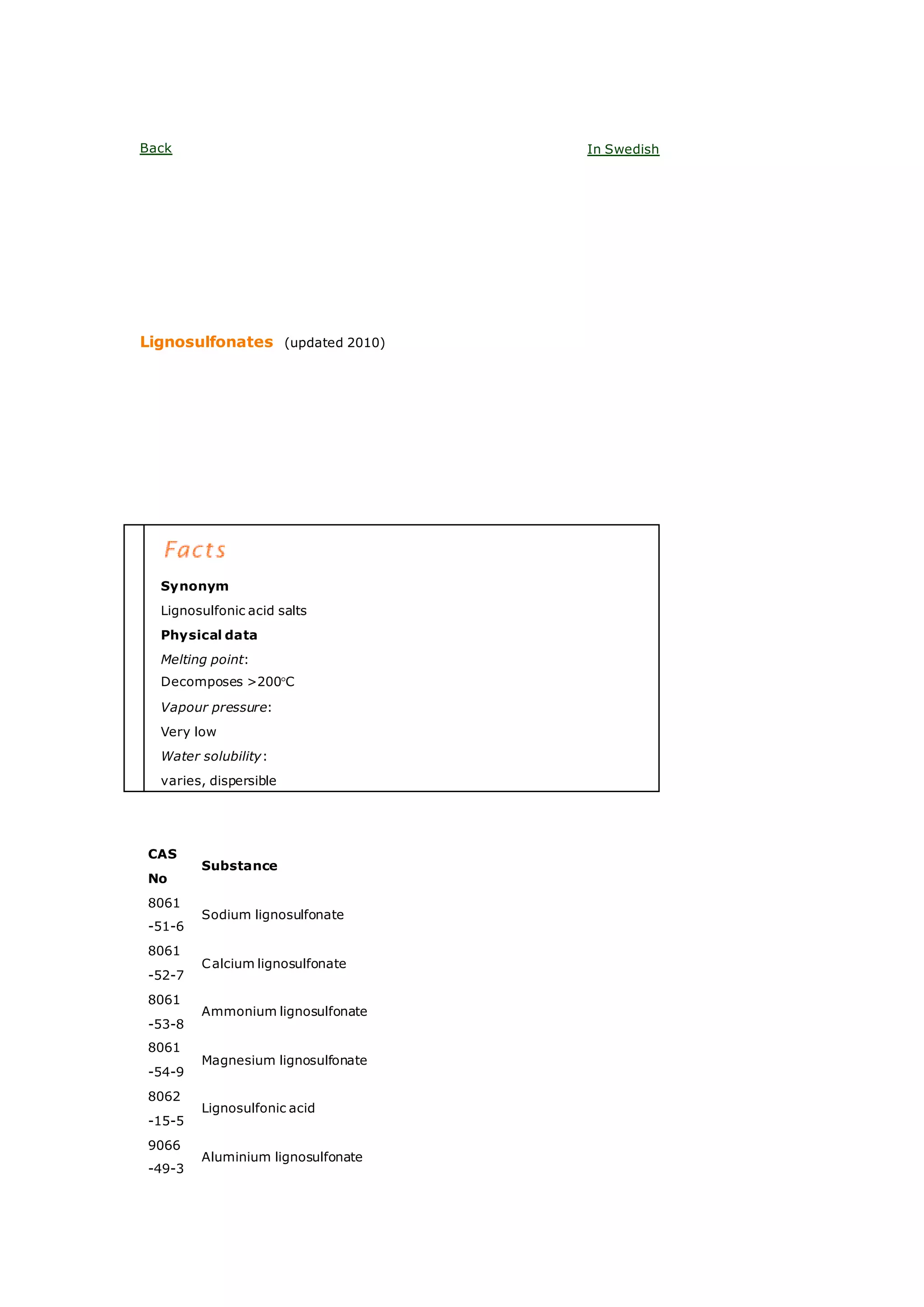

Lignosulfonates are biopolymers that are salts of lignosulfonic acid formed during the production of pulp using the sulfite method. They have varied compositions depending on the type of wood used and extent of lignin degradation. Lignosulfonates are precipitated as calcium salts from spent process liquid generated during sulfite pulping and are used as additives in products like cement, lead batteries, and ceramics due to their surface-active properties which allow them to coat particles and improve binding. Major applications include use as a cement additive, dust suppressant, and dispersant.