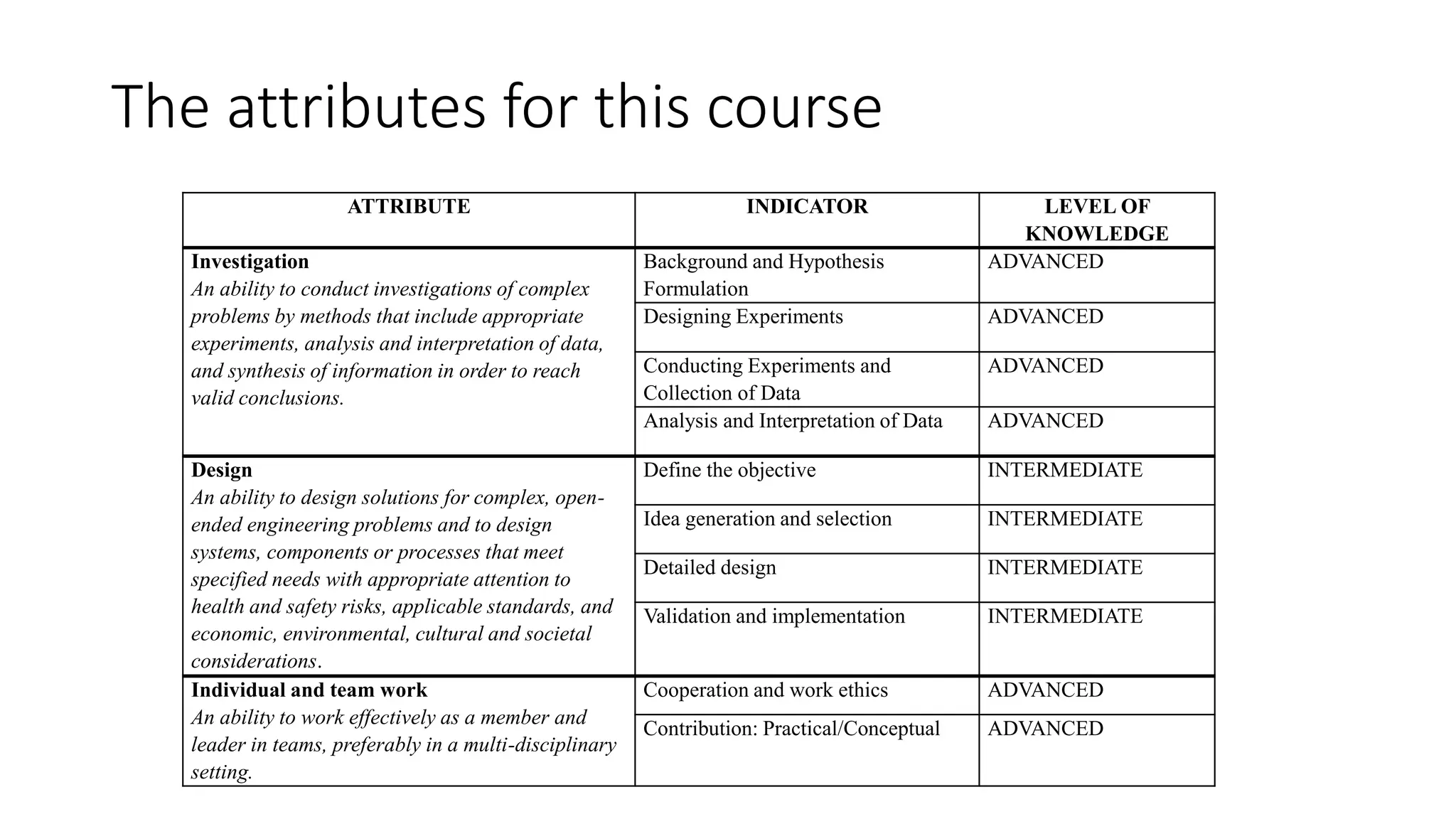

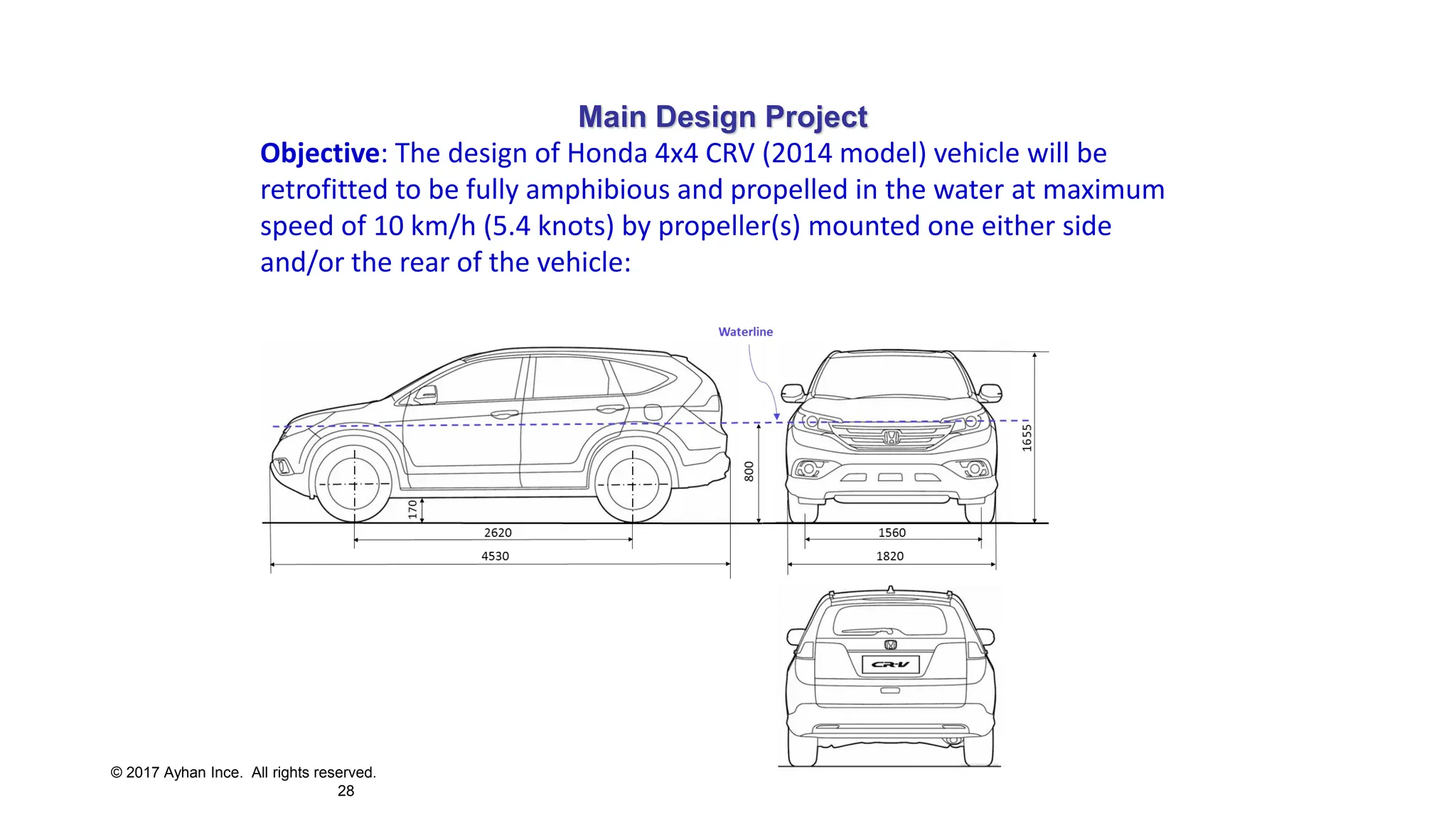

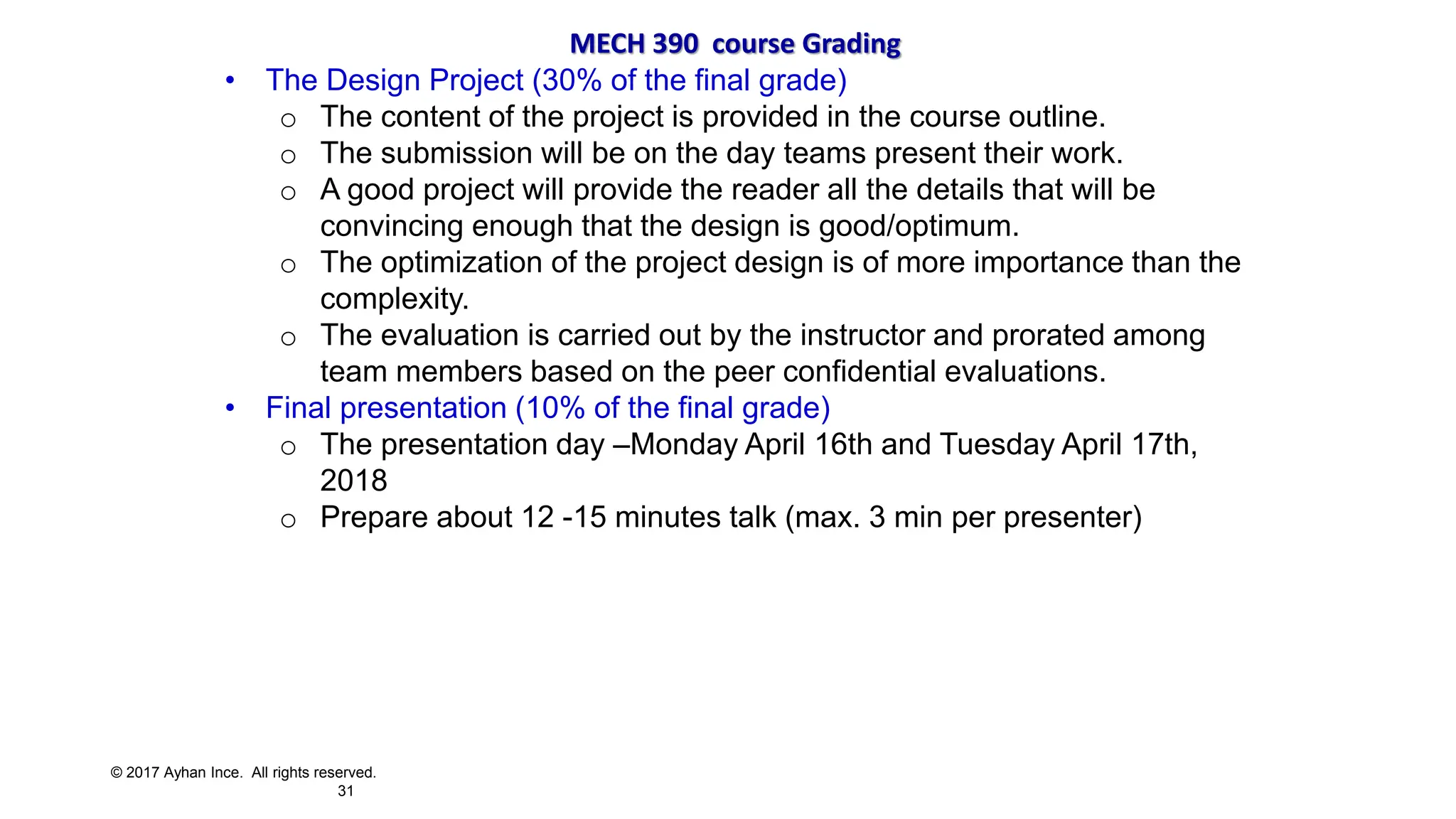

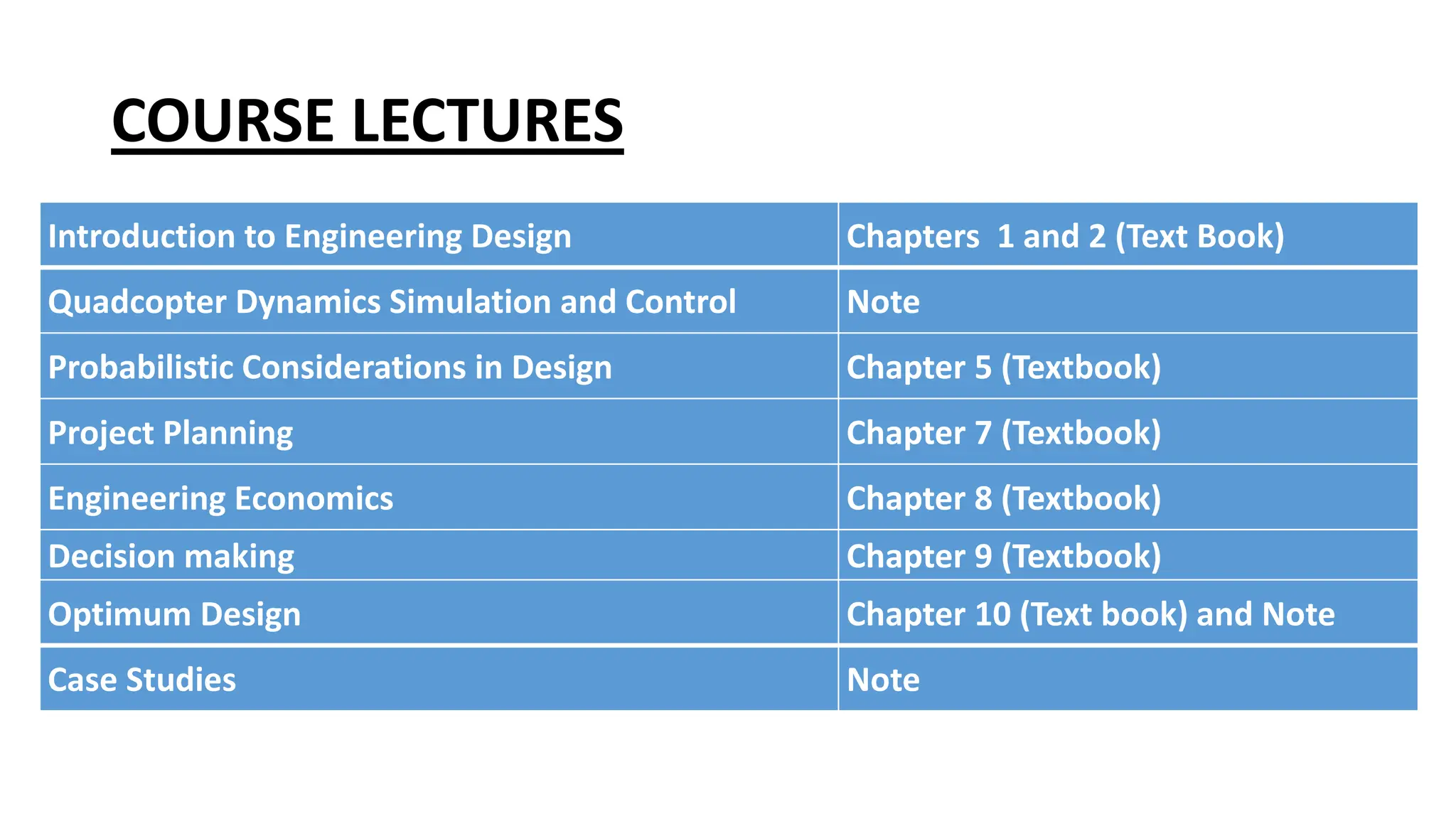

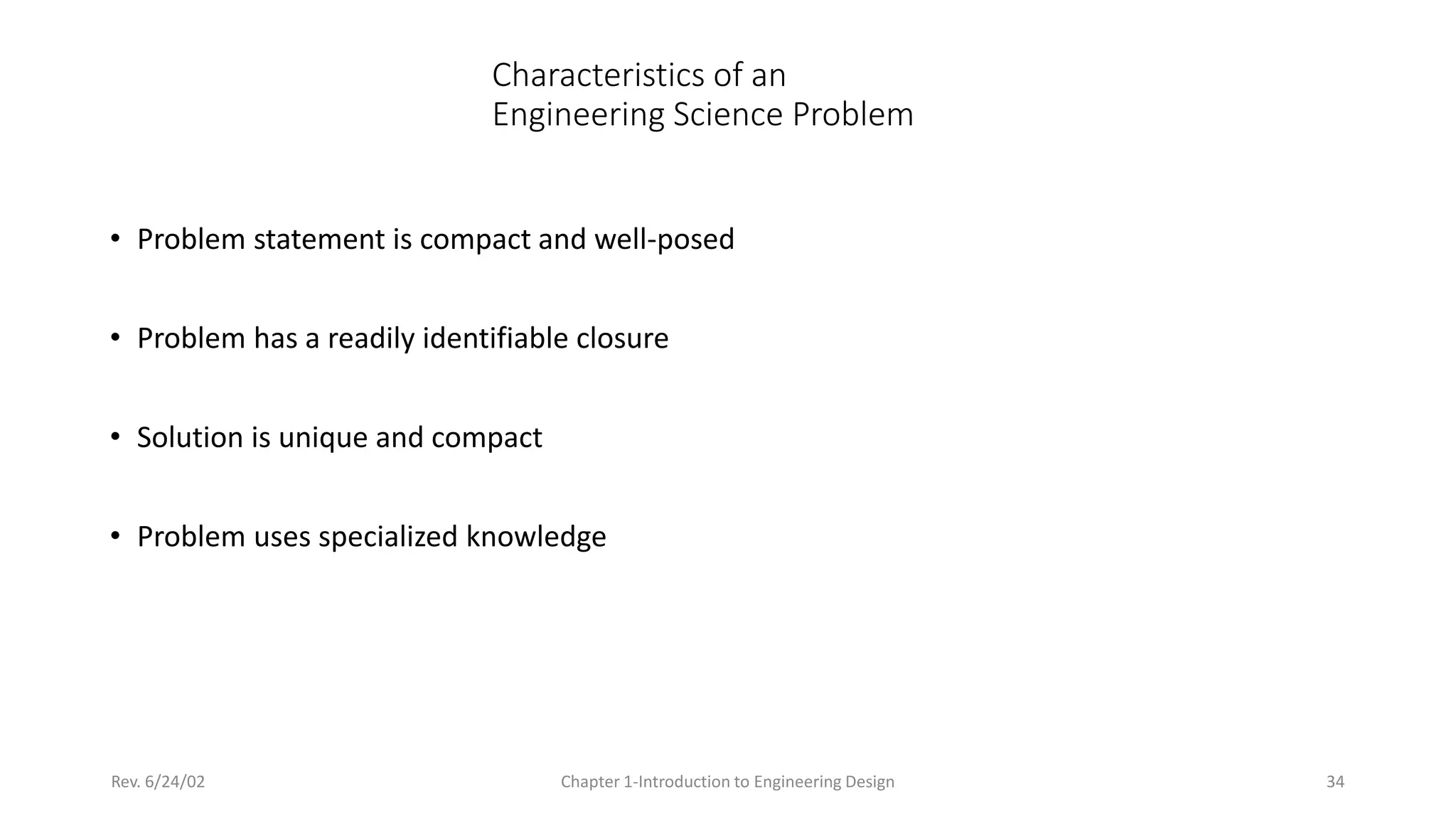

This document provides an overview and outline for a Mechanical Engineering Design Project course (MECH 390). It discusses expectations for the course which include completing a design project in a team, taking a midterm exam, tutorials, and quizzes. Students are expected to apply engineering skills to open-ended problems through concepts, solutions, planning, decision making, modeling, prototyping, and communication. Success requires attention in lectures, studying documentation, and attendance to learn skills needed for engineering design in their career.