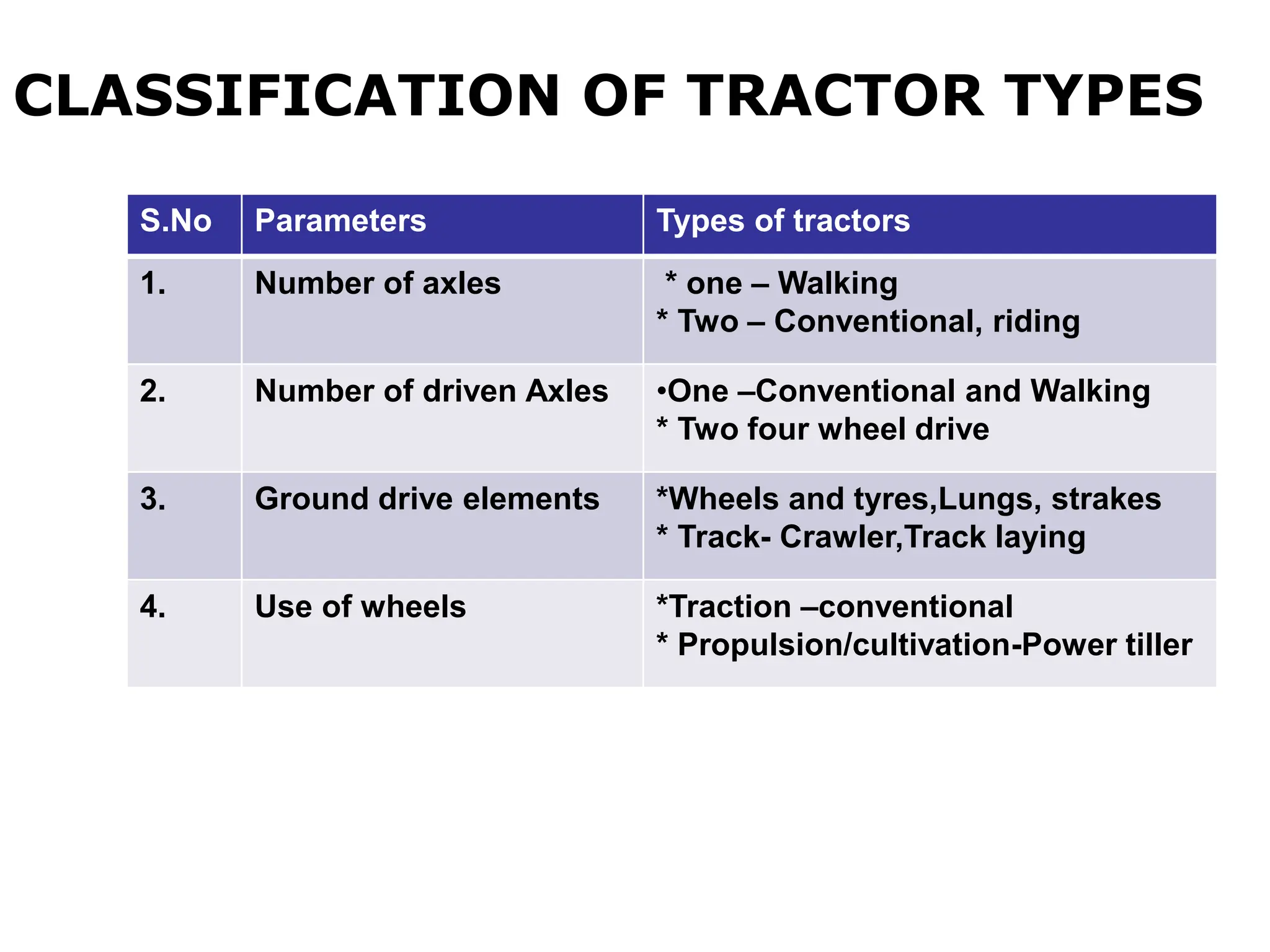

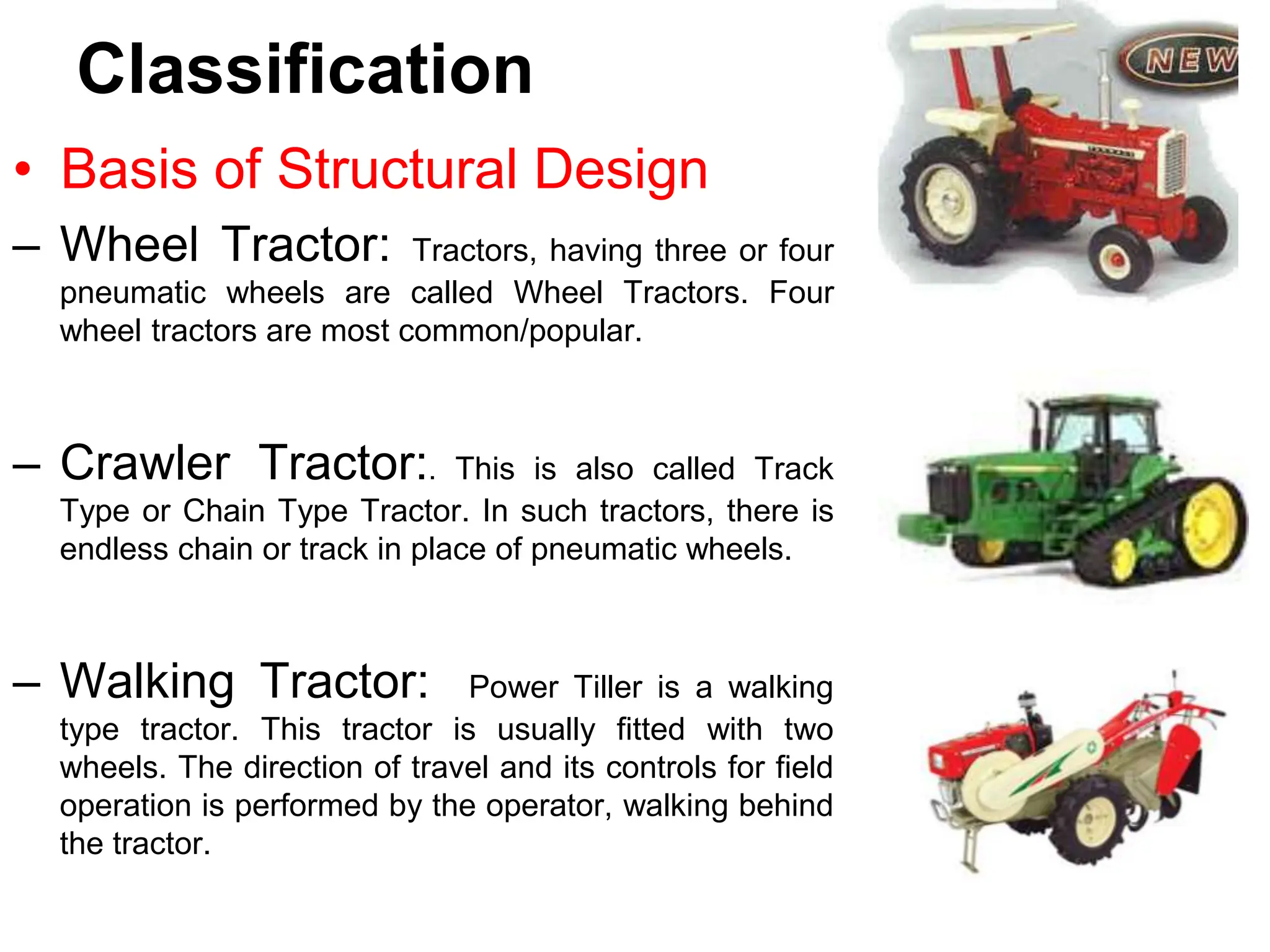

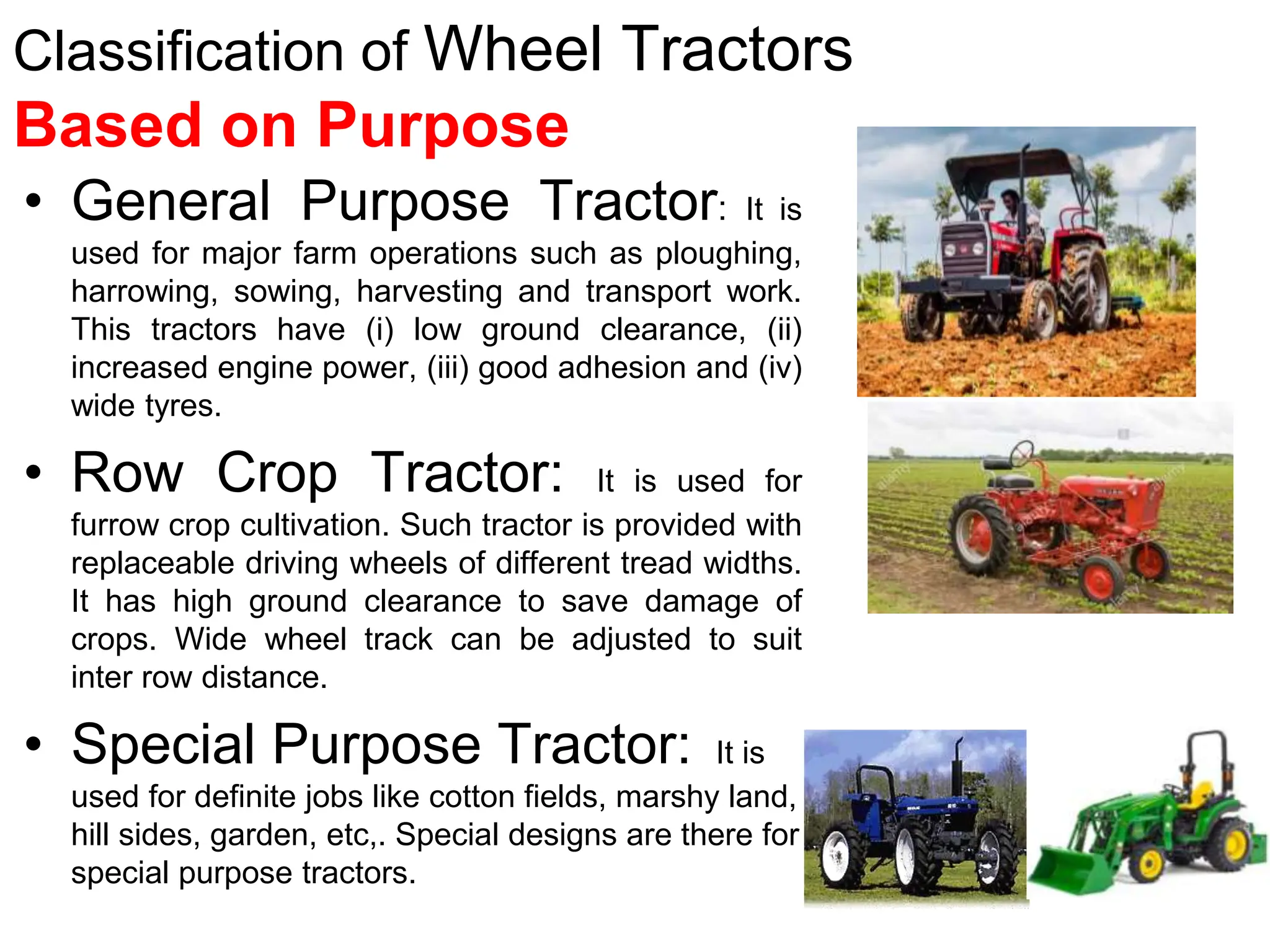

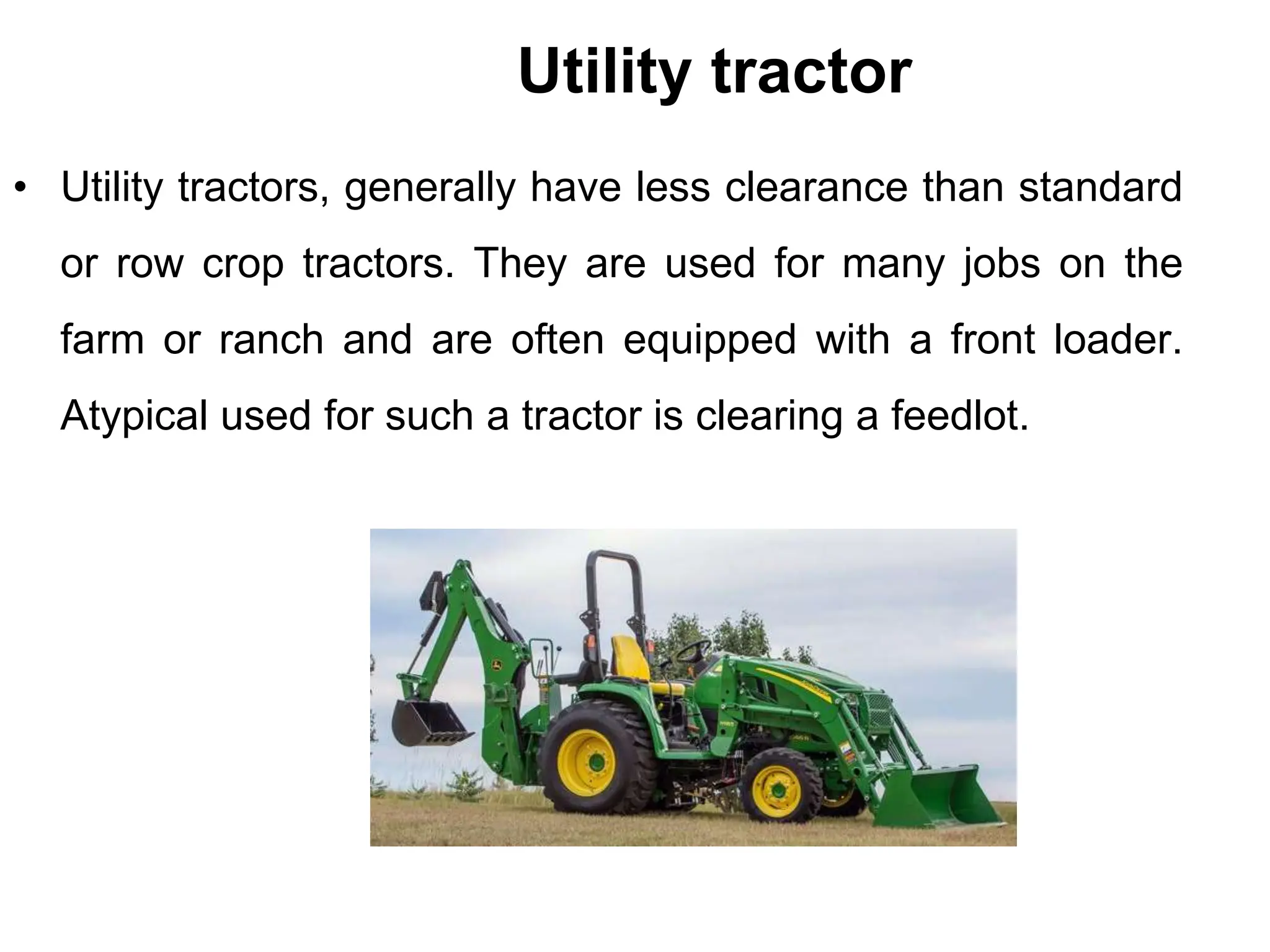

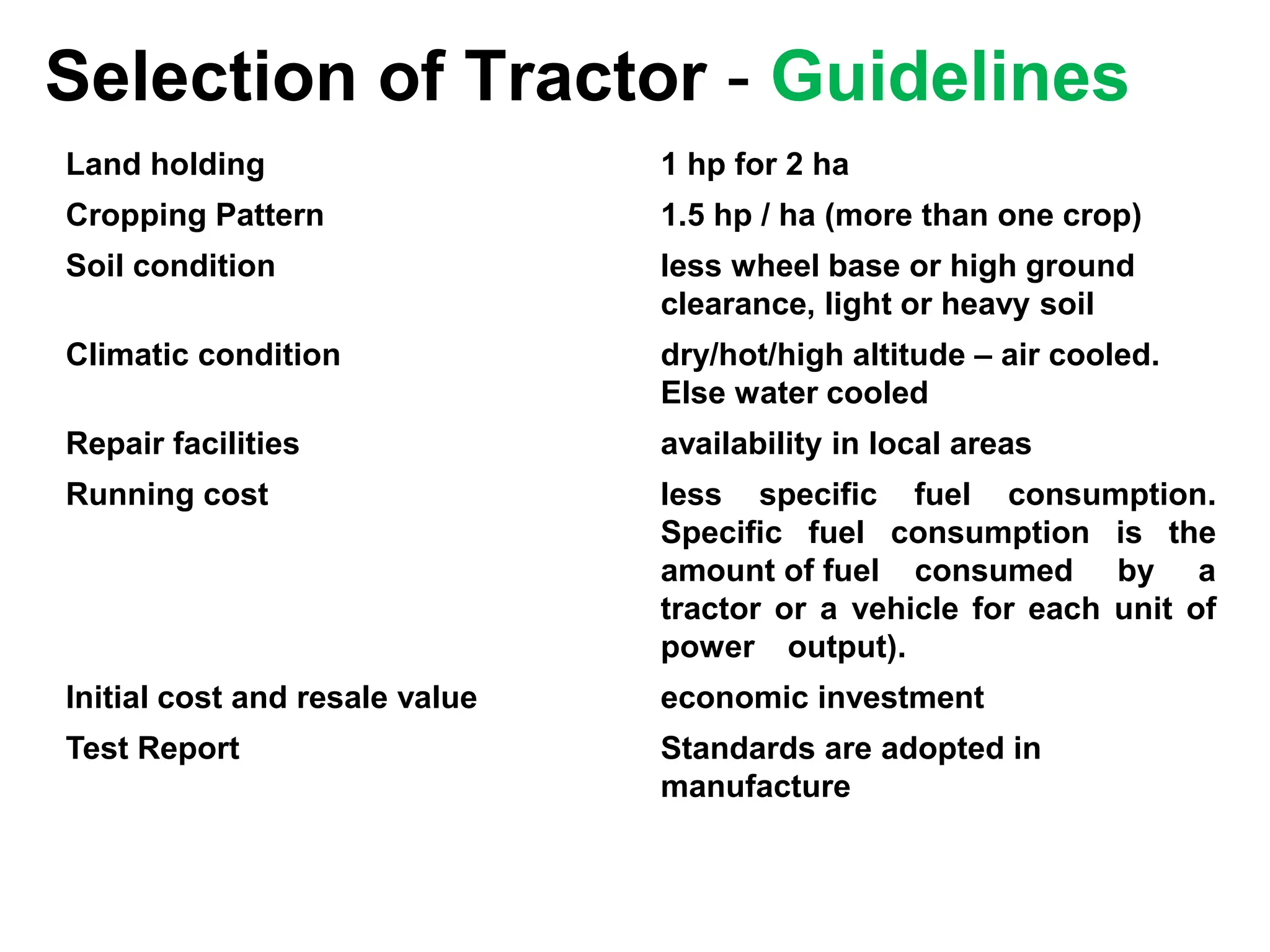

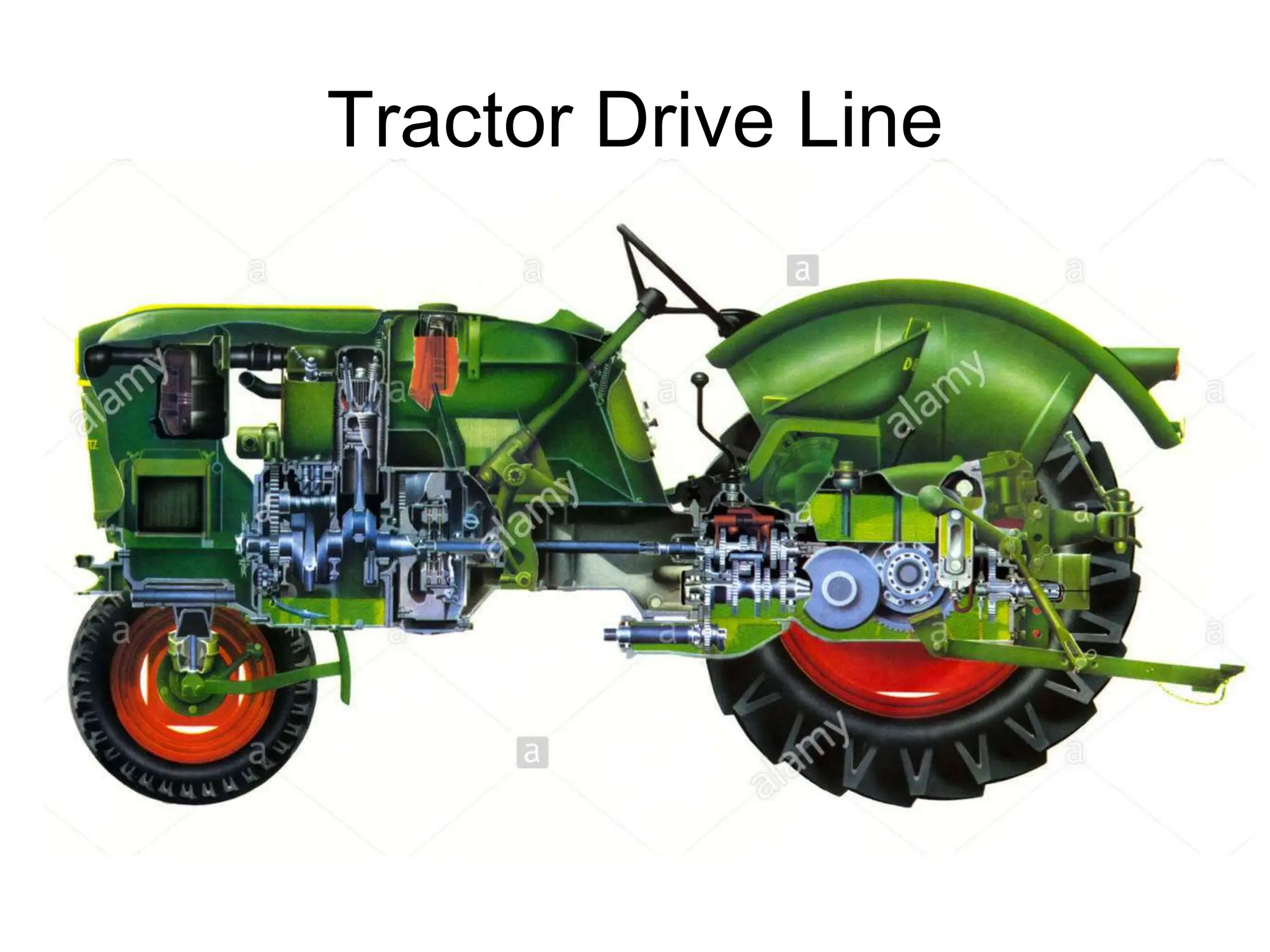

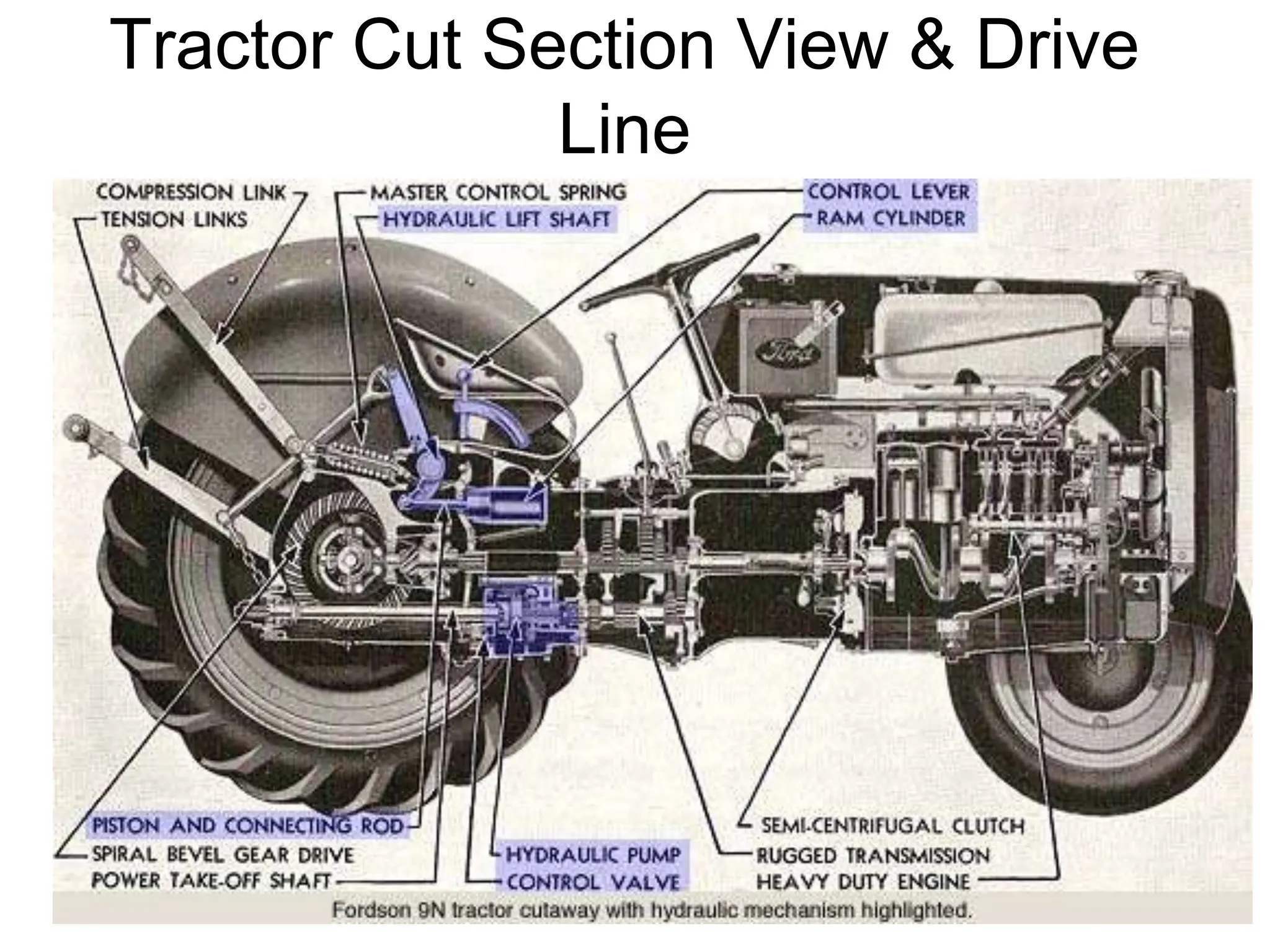

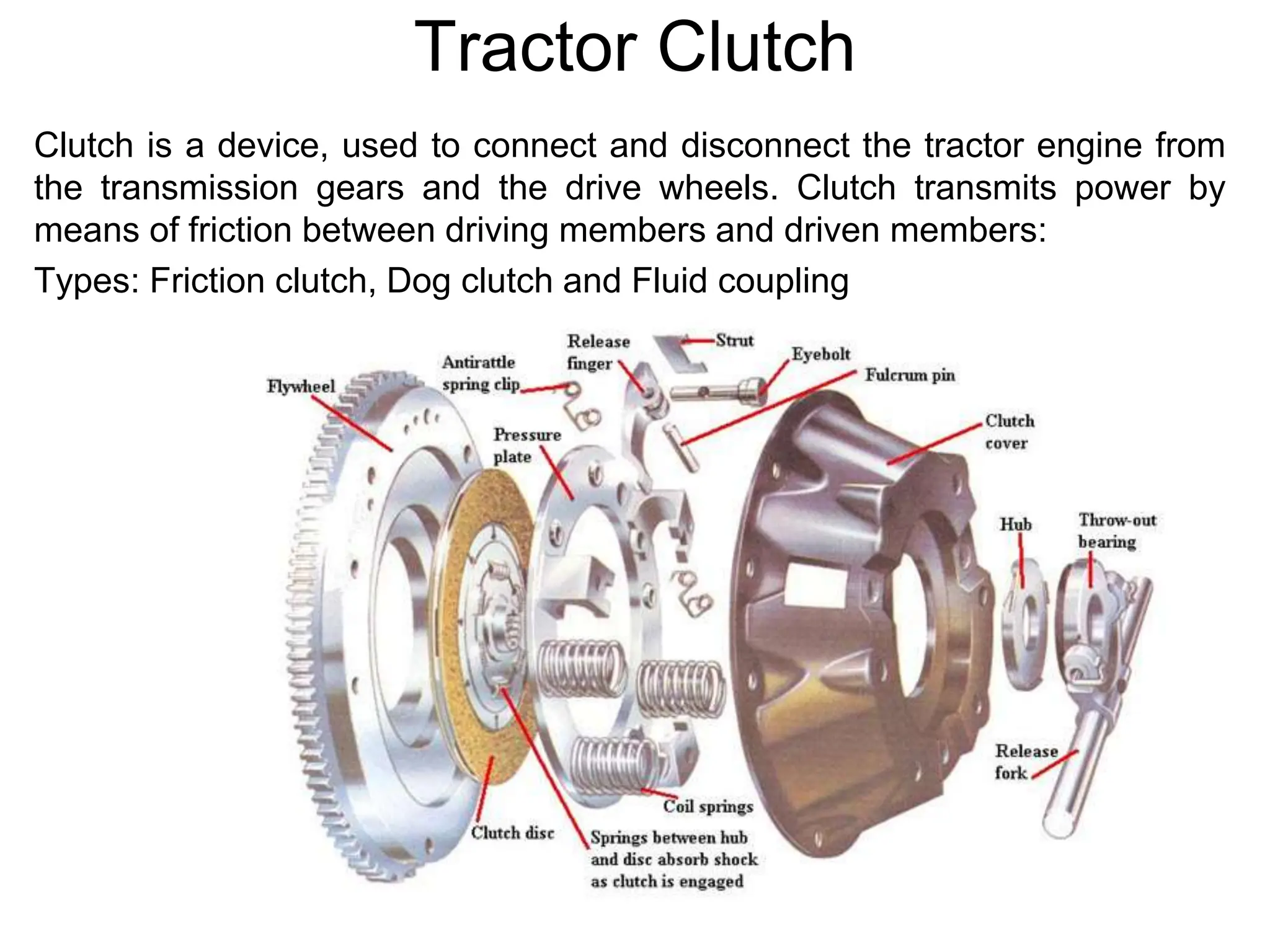

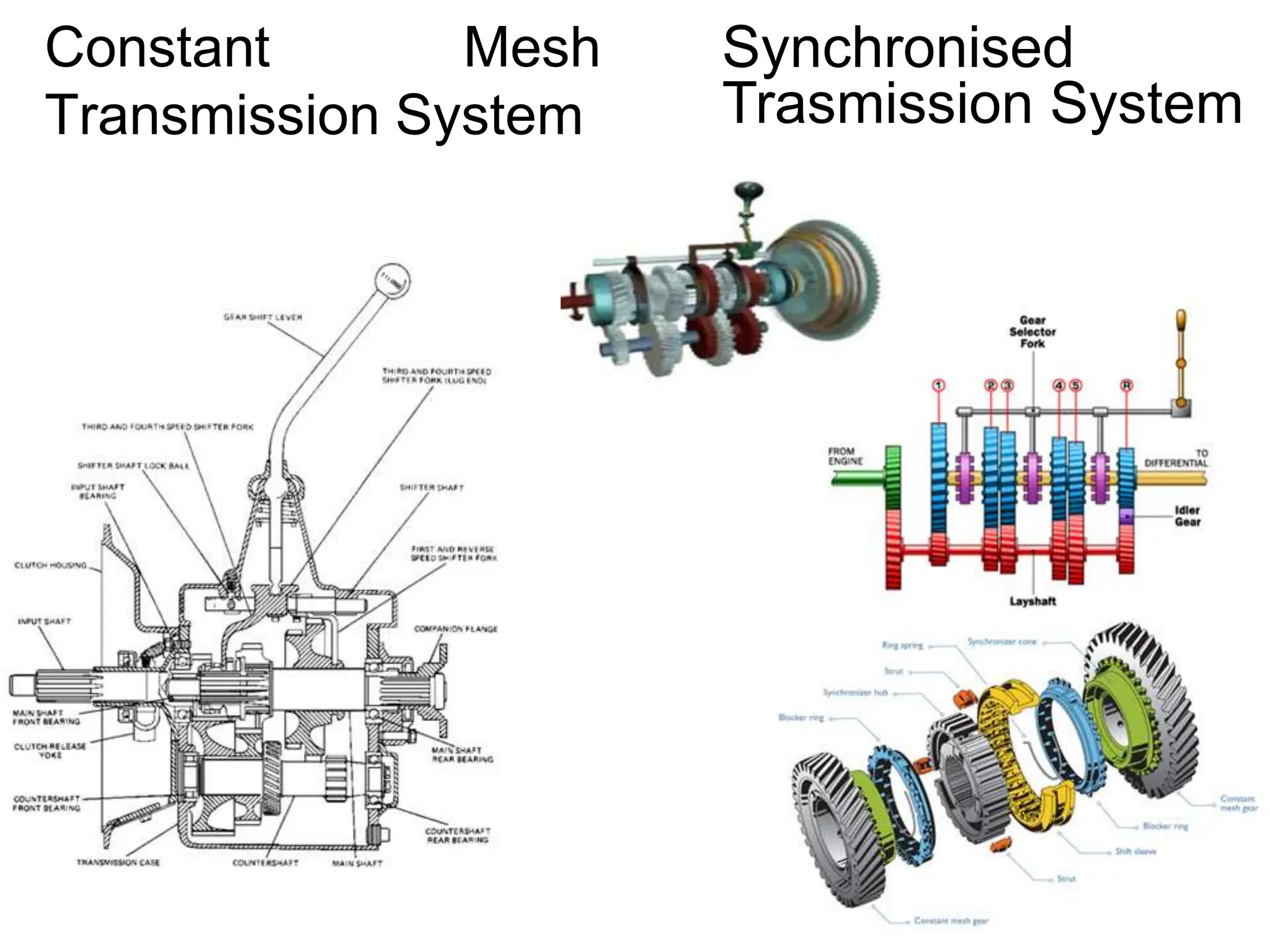

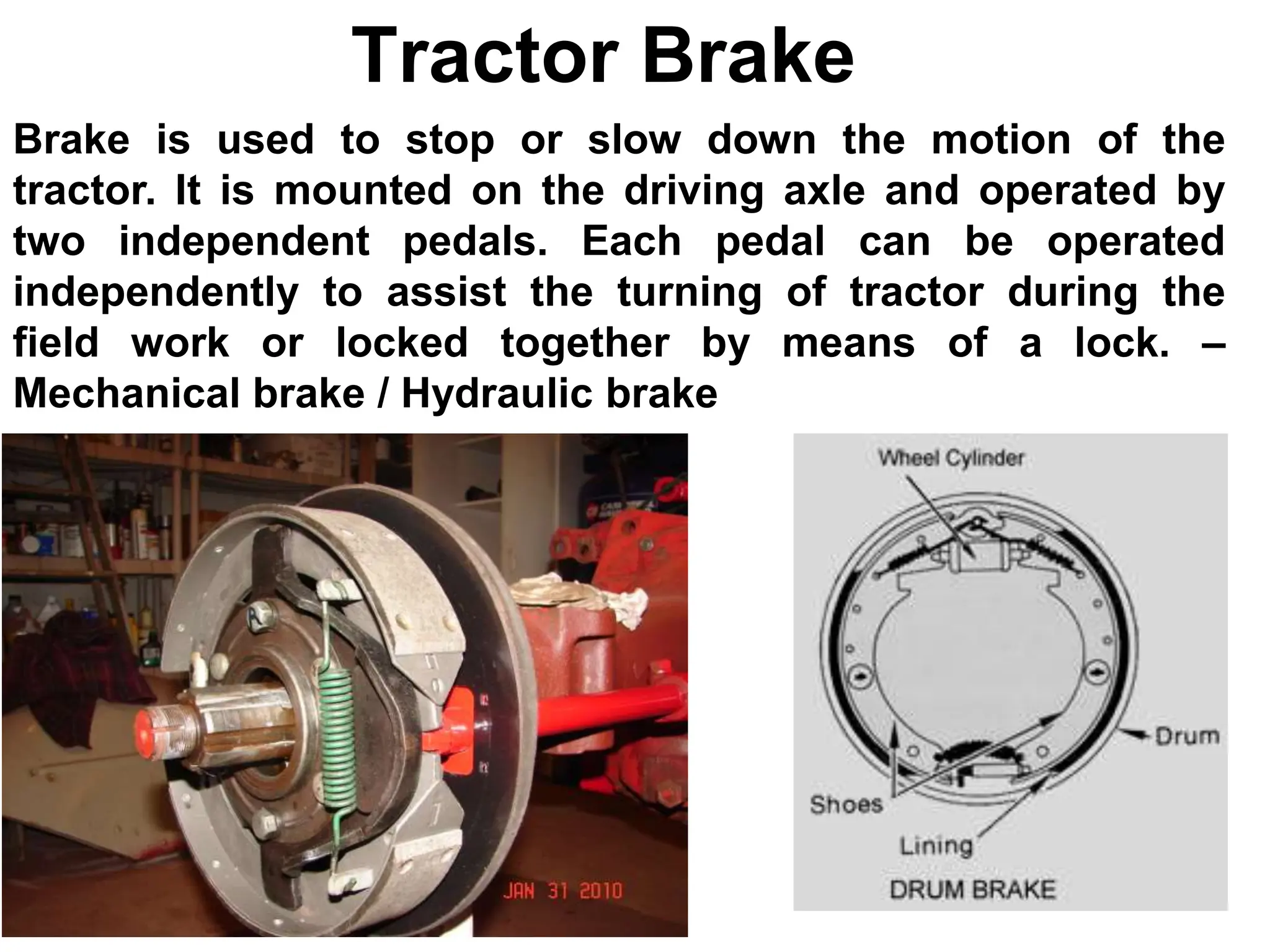

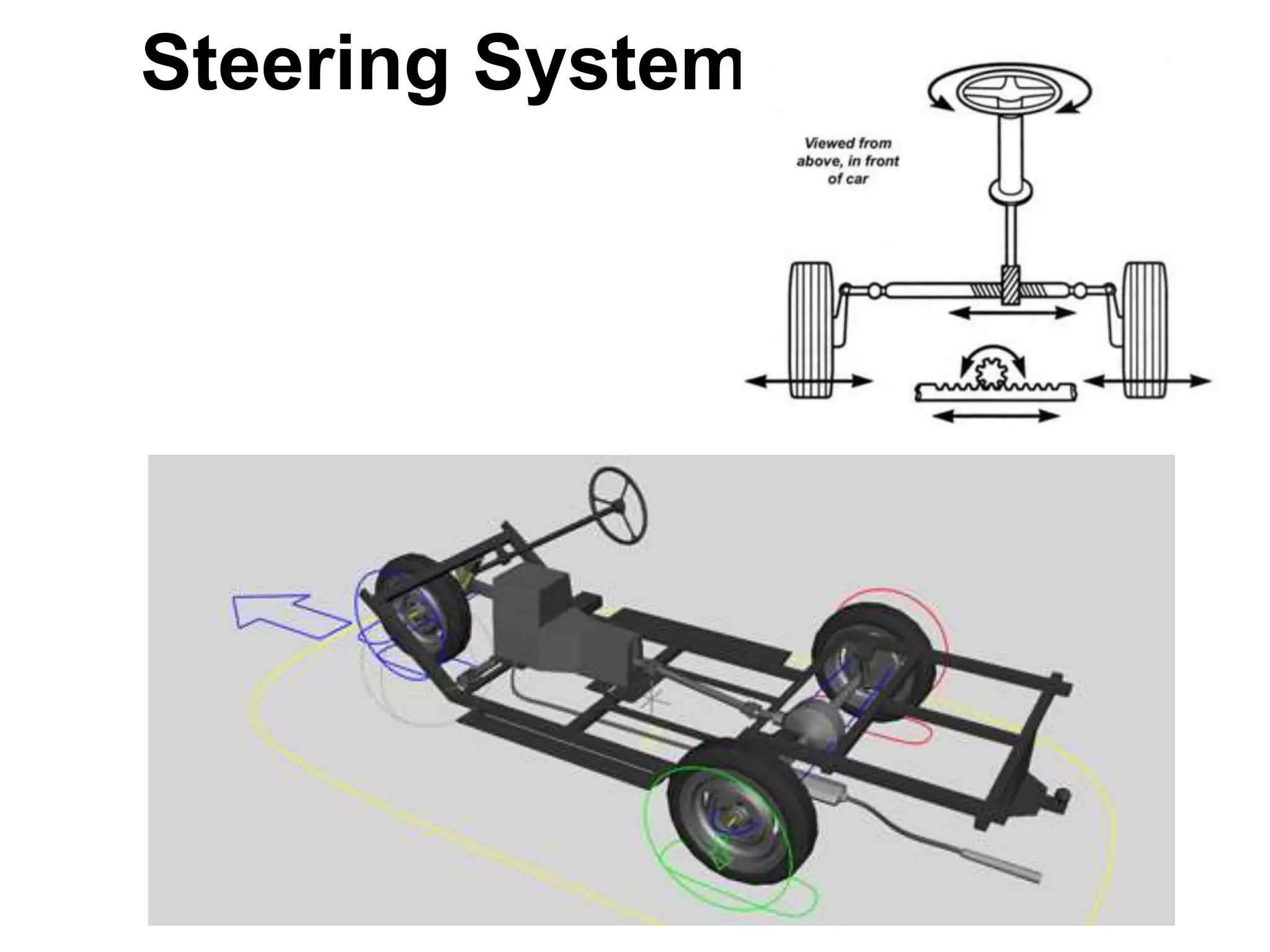

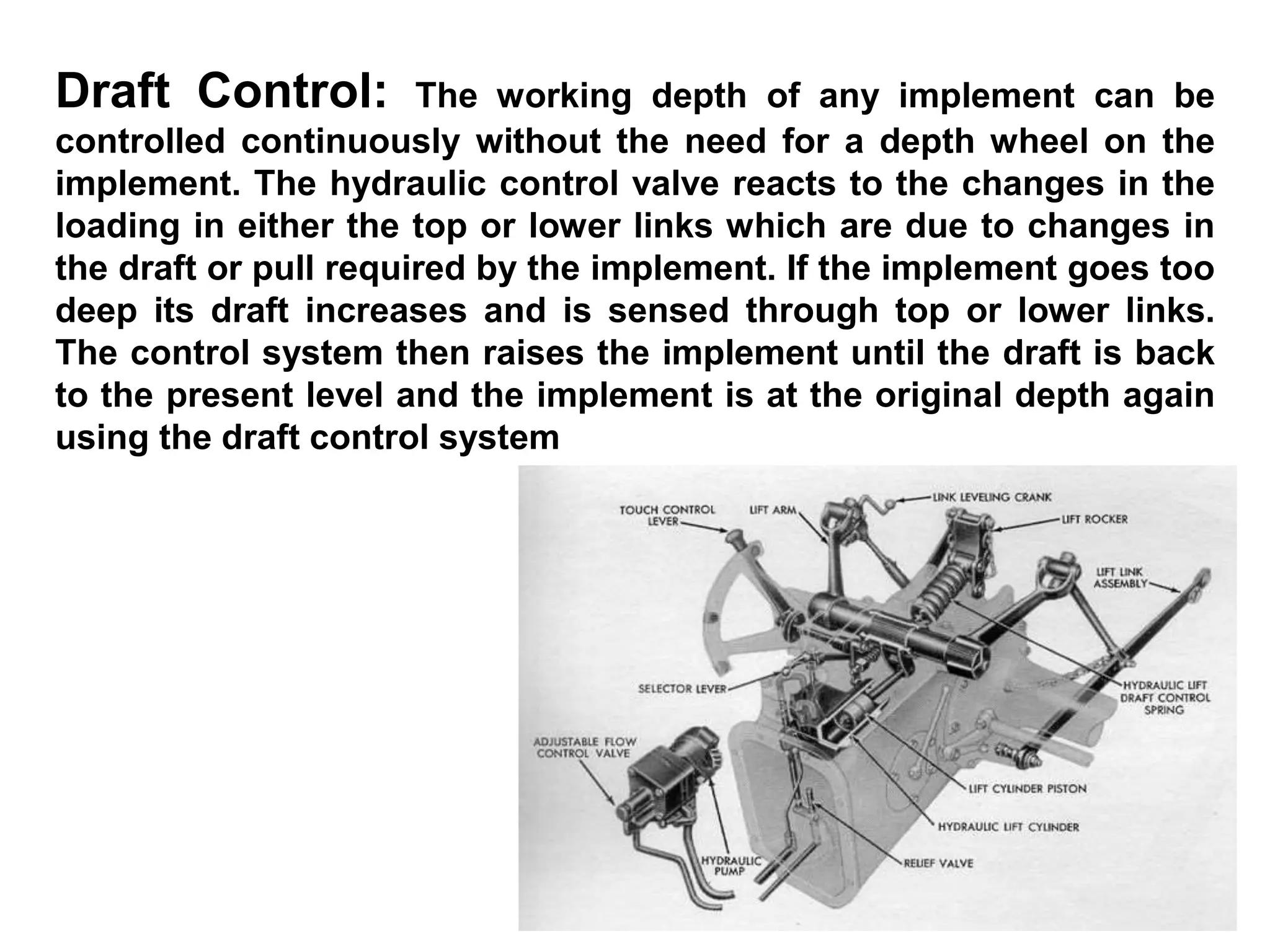

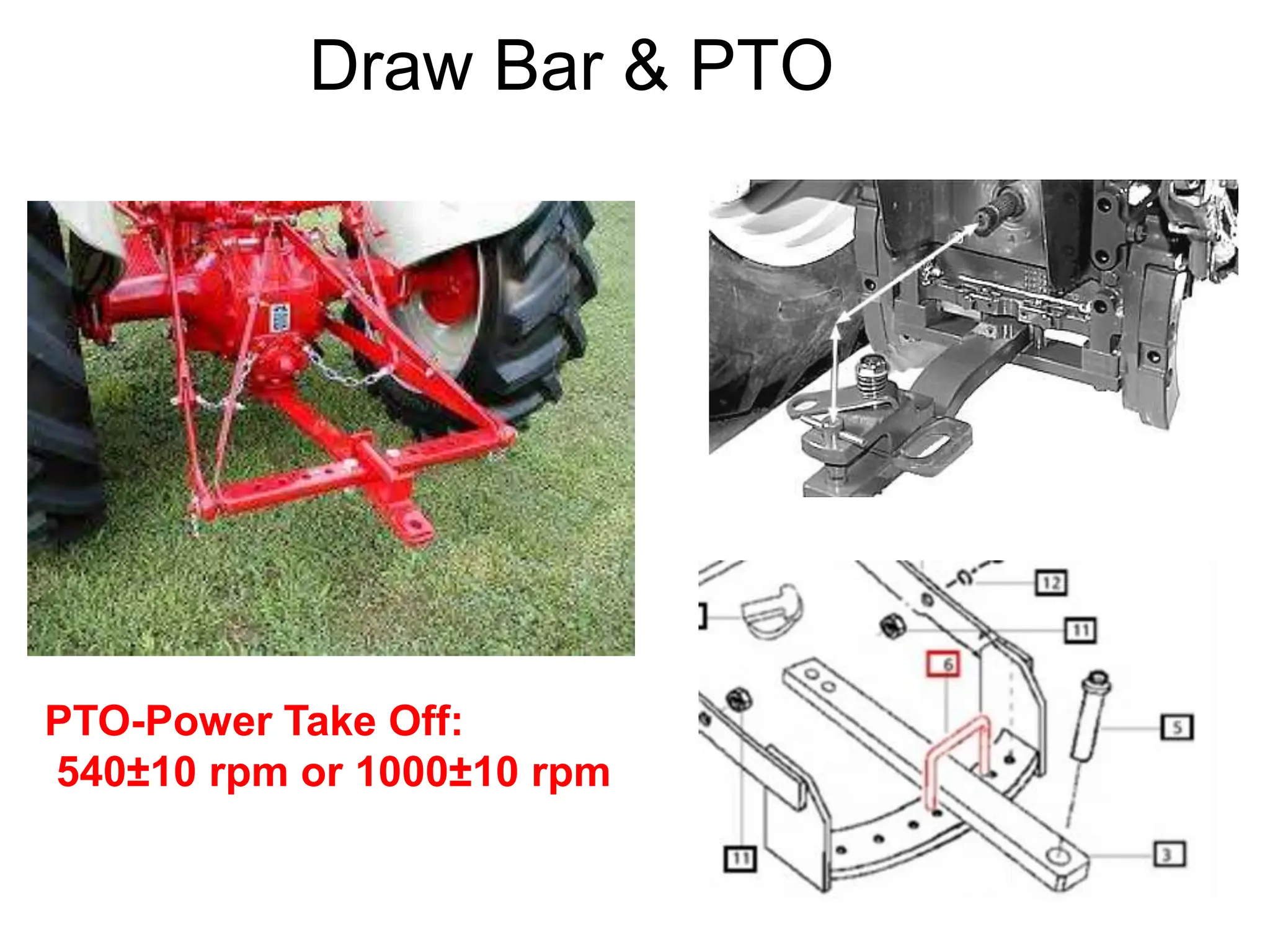

The document provides an in-depth overview of tractors, detailing their types, transmission systems, hydraulic systems, and historical development in agriculture. It classifies tractors based on power, structure, and purpose, discussing major components like clutches, gearboxes, and hydraulic controls. Additionally, it covers the evolution of tractor technology and presents guidelines for selecting suitable tractors based on land, cropping patterns, and other parameters.