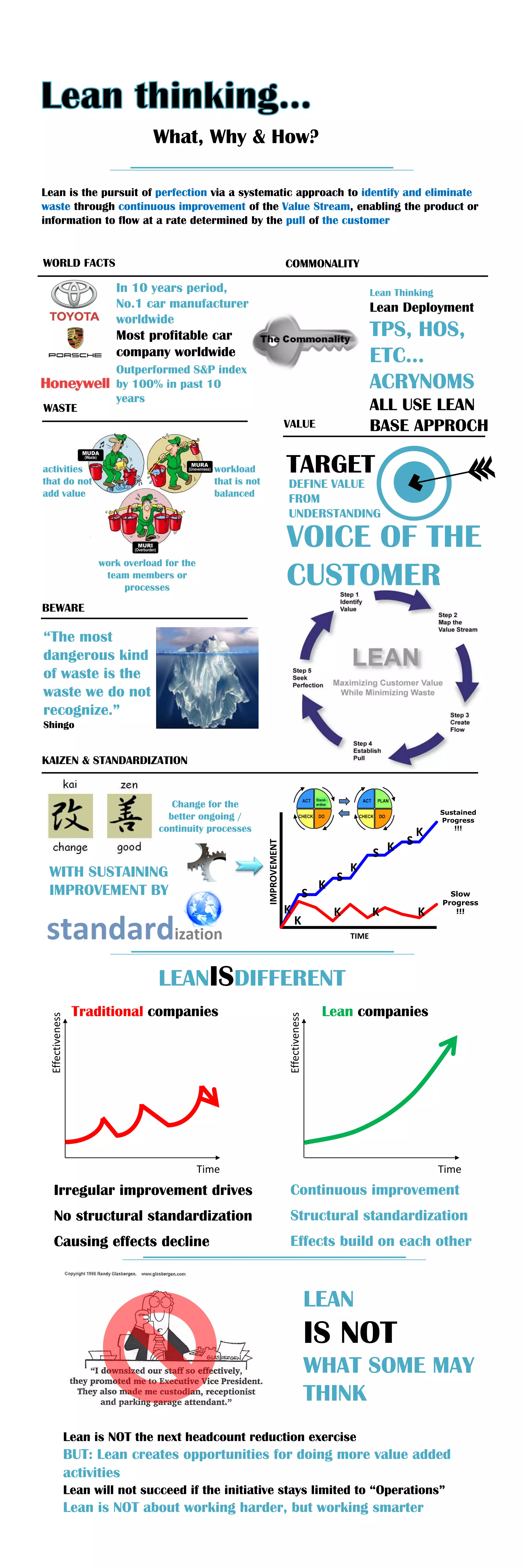

Lean is a systematic approach to identify and eliminate waste through continuous improvement of processes. The goal is to allow value to flow at a rate determined by customer demand. Lean thinking has helped many companies become the most profitable in their industries through outperforming competitors and stock market indices. Key aspects of lean include defining value from the customer perspective, standardizing processes, and pursuing ongoing kaizen (continuous improvement) to sustain gains over time through built-up effectiveness, rather than irregular improvements. Lean is not just a cost-cutting exercise but a way to do more value-added work through working smarter, not harder, with benefits extending beyond operations.