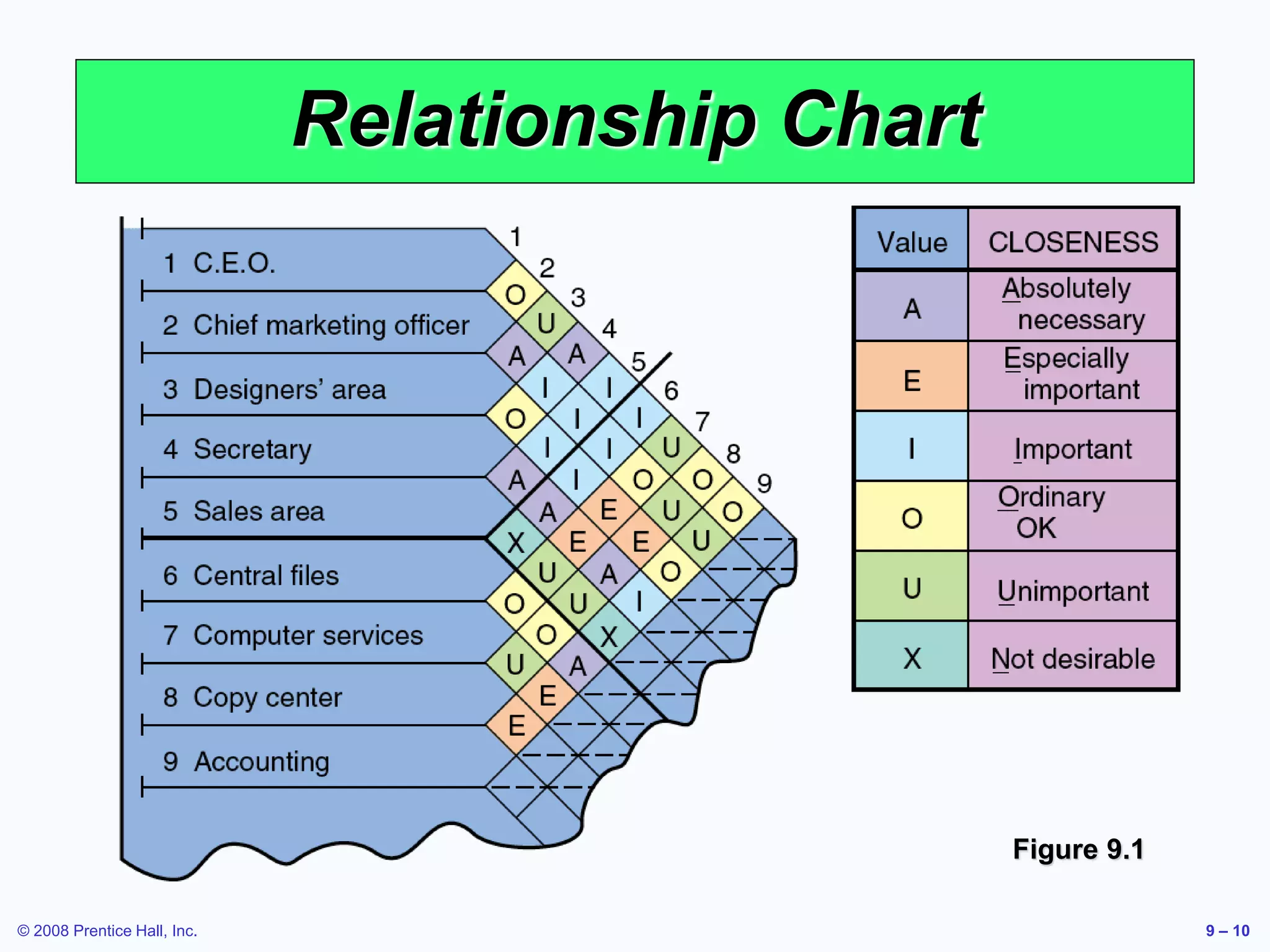

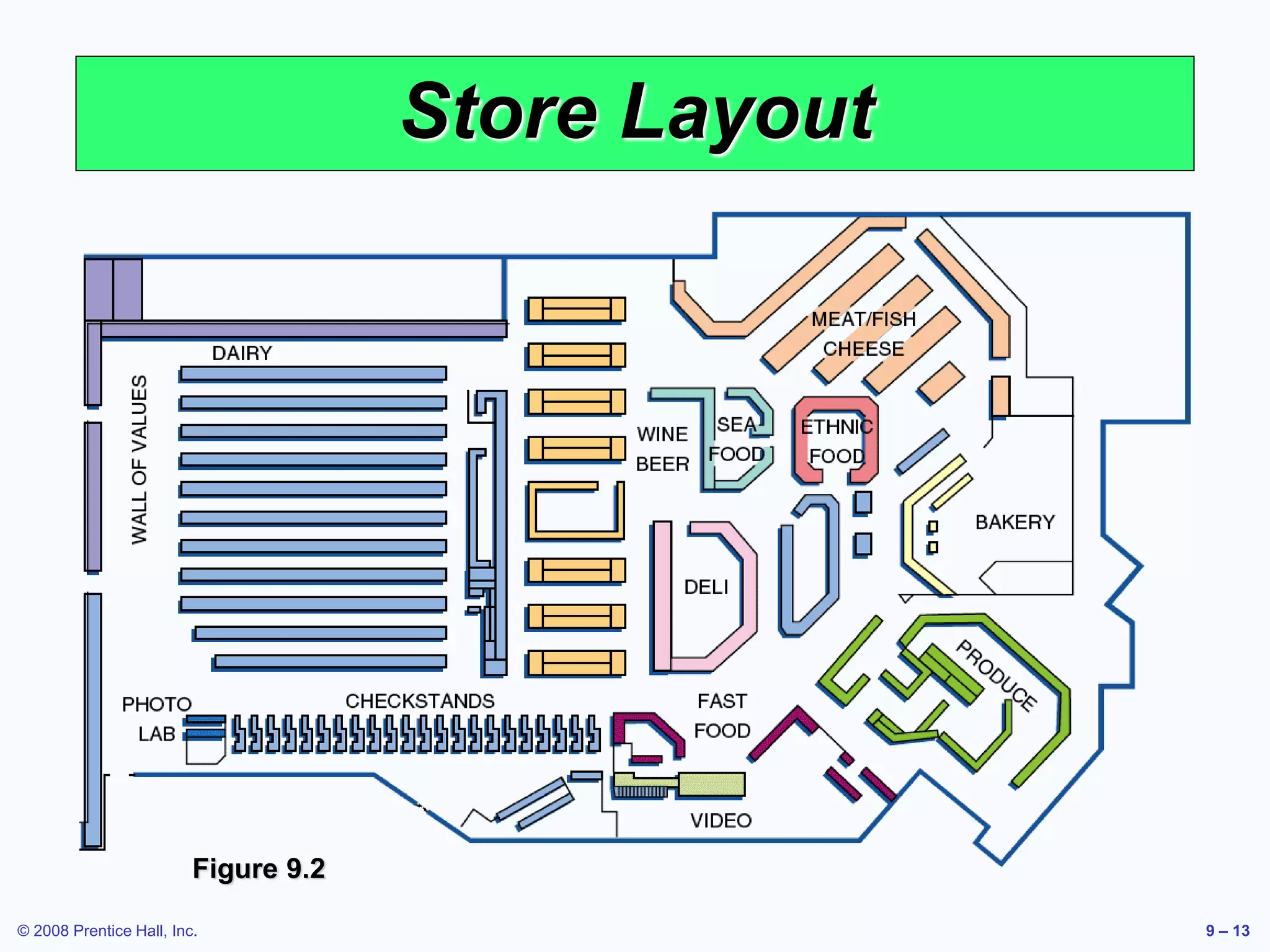

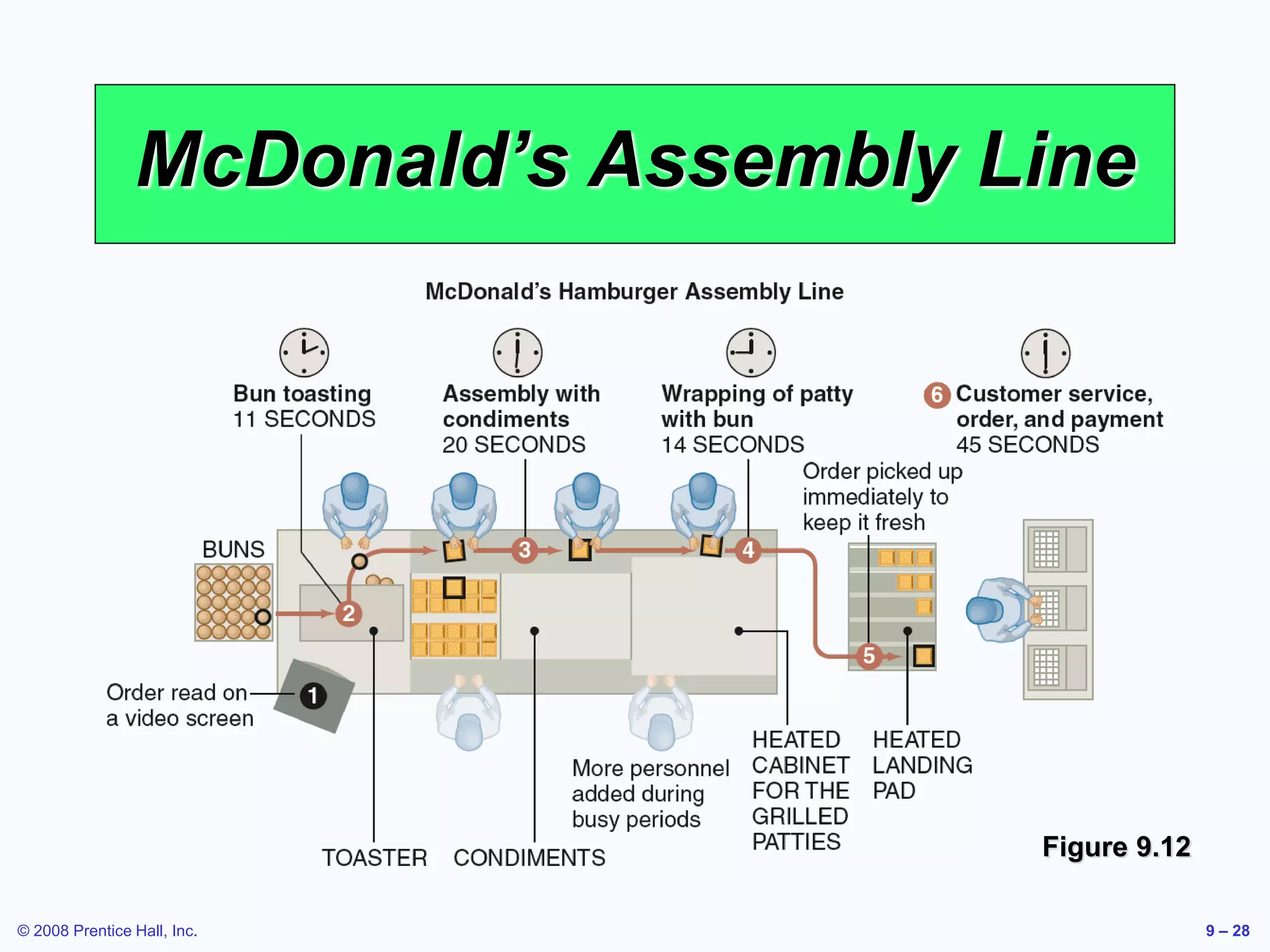

The document discusses various layout strategies and types of layouts. It describes layout as developing a cost-effective plan to meet a firm's competitive needs by optimizing space, flow, employee morale and safety, and customer interaction. It outlines types of layouts including office, retail, warehouse, fixed position, process-oriented, work cell, and product-oriented layouts. For each type, it provides examples and considerations for design and optimization.