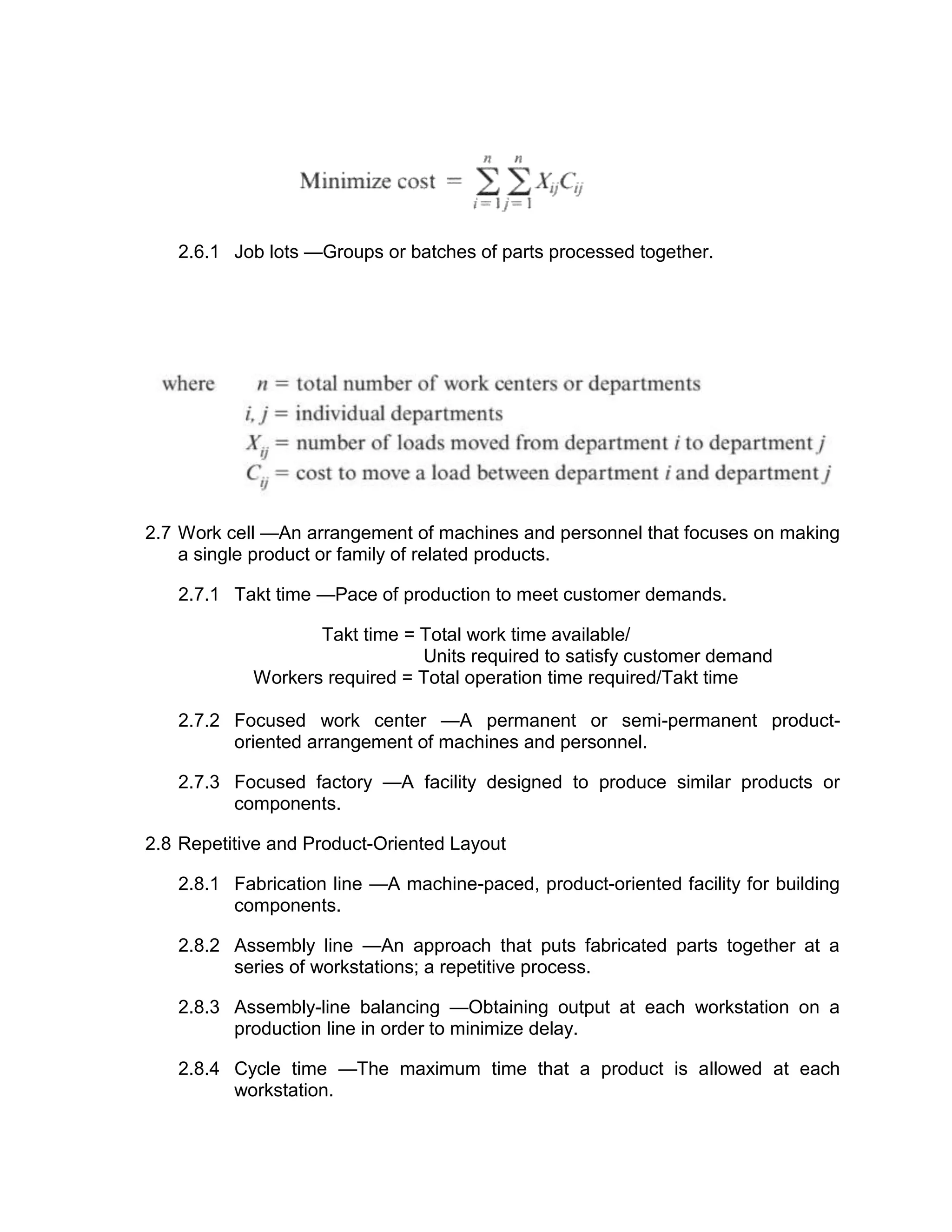

The document outlines a 4 hour module on layout strategies. It discusses the importance of layout decisions and different types of layouts including office, retail, warehouse, fixed-position, process-oriented, work-cell, and product-oriented layouts. Examples and objectives of each type of layout are provided. The learning procedures include an activity to design a store layout and a lesson discussing the strategic importance of layout decisions and various layout types and considerations.