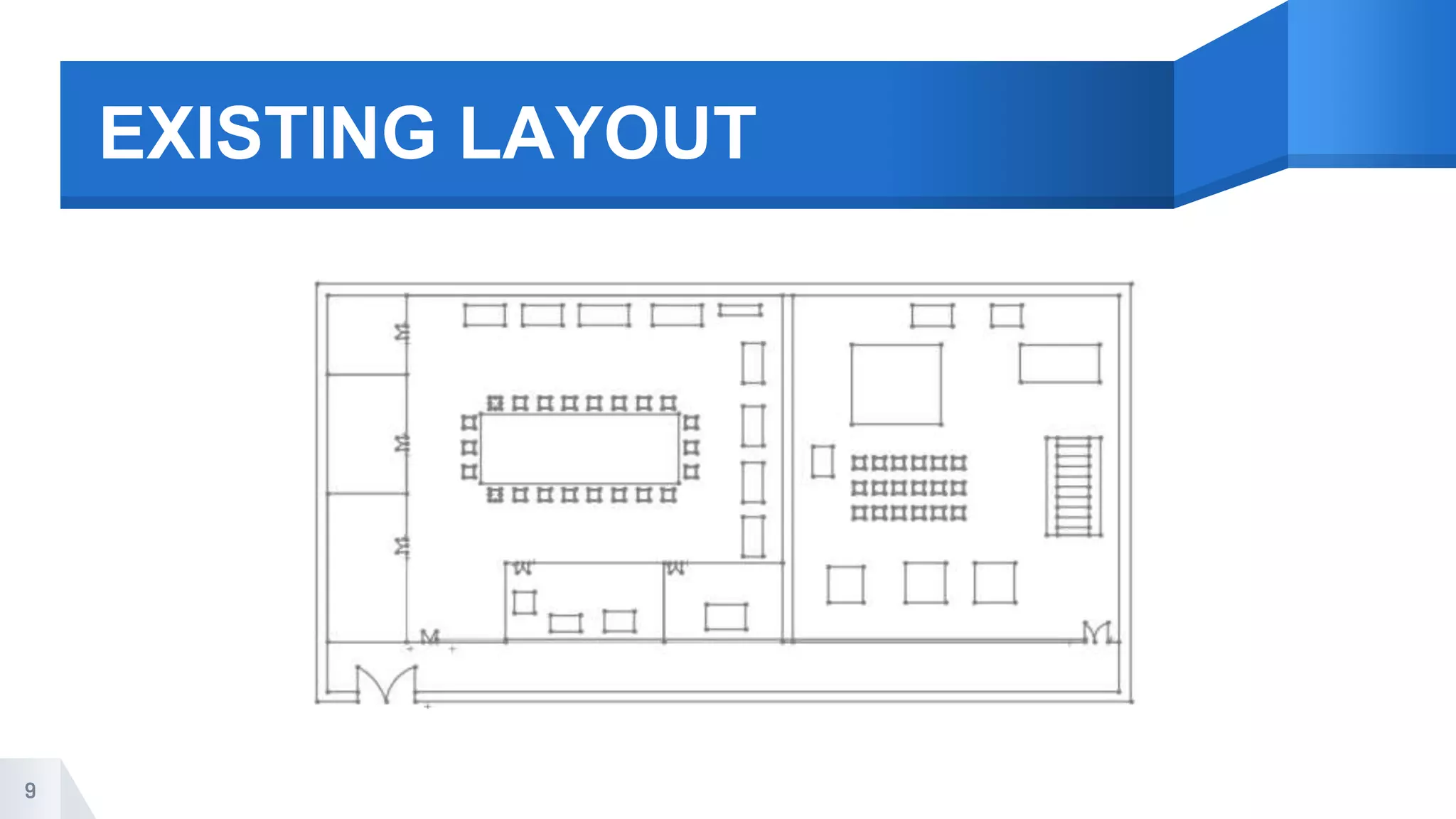

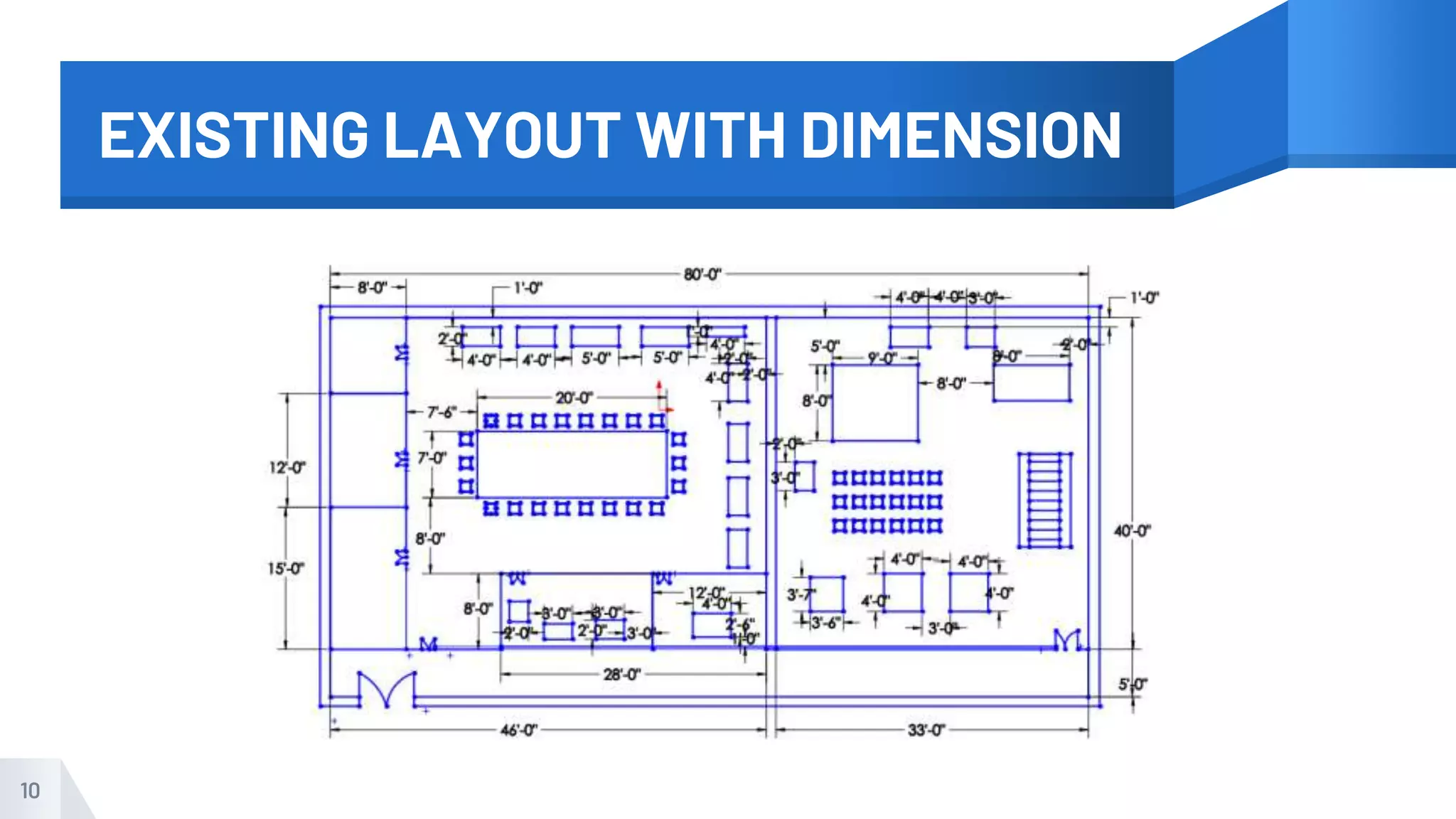

This document summarizes a study of the layout plan of a metrology lab at RUET. It outlines the objectives, which are to study different layout types and how layout influences material handling, and to propose a new layout to optimize the system. It describes the existing layout, notes issues like inefficient space usage, and proposes a new layout that increases floor space and allows better visualization of experiments. The conclusion is that the study helped learn about layout types and designing efficient layouts while considering material flow.

![TEAM MEMBERS

2

▸ MD. Rahul Chandra Paul [1605048]

▸ Md. Aliwar Hossain [1605049]

▸ Md. Raquibul Haque [1605050]

▸ Nahian Kawsar Sifat [1605052]

▸ Limon Mia [1605054]

▸ Bulbul Biswas [1605056]

▸ Anika Bushra [1605057]

▸ MD. Sakawat Hossain Sohan [1605059]

▸ Ar Rafi Hridoy [1605060]](https://image.slidesharecdn.com/metrology-lab-220624164041-eb6c3885/75/LAYOUT-PLAN-OF-RUET-METROLOGY-LAB-2-2048.jpg)