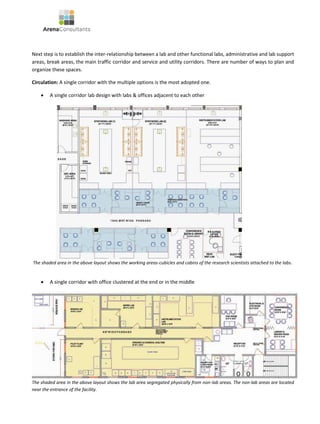

The document provides guidance on basic considerations for designing a laboratory. It discusses classifications of wet and dry labs and concepts for lab planning such as zoning lab and non-lab areas, circulation, and module design. Key factors covered include flexibility, functionality, safety, aesthetics, and cost-effectiveness. The document emphasizes identifying user needs, allowing for future expansion, and integrating mechanical, electrical and plumbing systems during initial planning to reduce costs and facilitate operations.