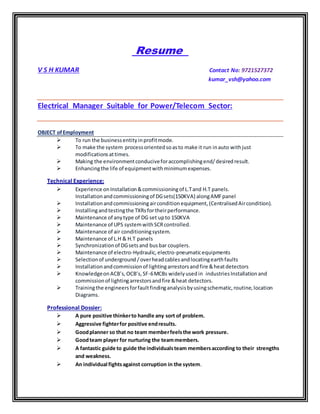

V S H Kumar has over 30 years of experience in electrical engineering, including 20 years in the Indian Air Force working on various electrical systems and equipment maintenance. He has worked in managerial roles overseeing operations and maintenance for various power and telecom companies. His experience includes installation, commissioning, and maintenance of equipment such as generators, UPS systems, air conditioning, panels, cables, and more. He is skilled in planning, team leadership, and achieving goals like high uptime and cost reduction.