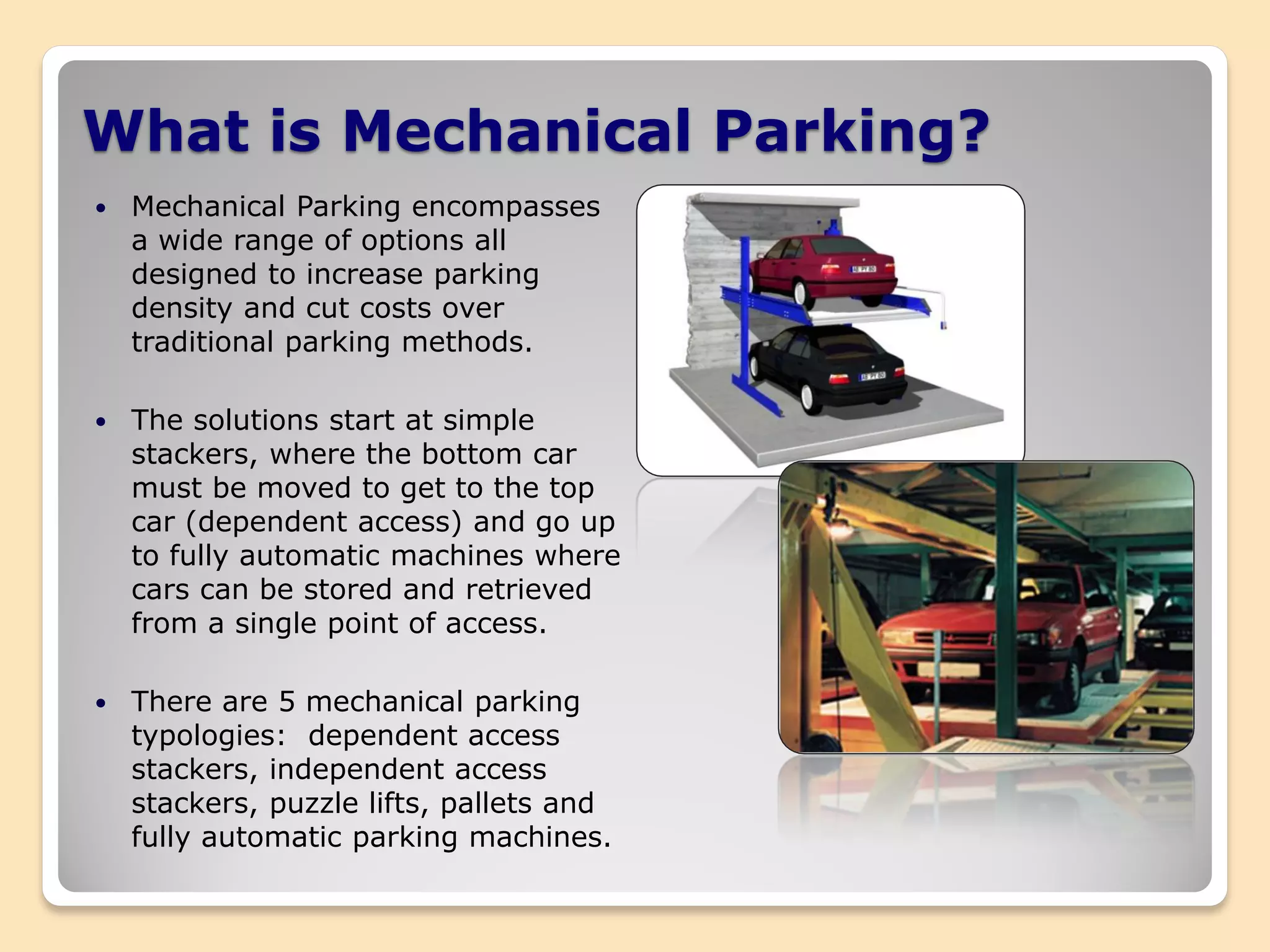

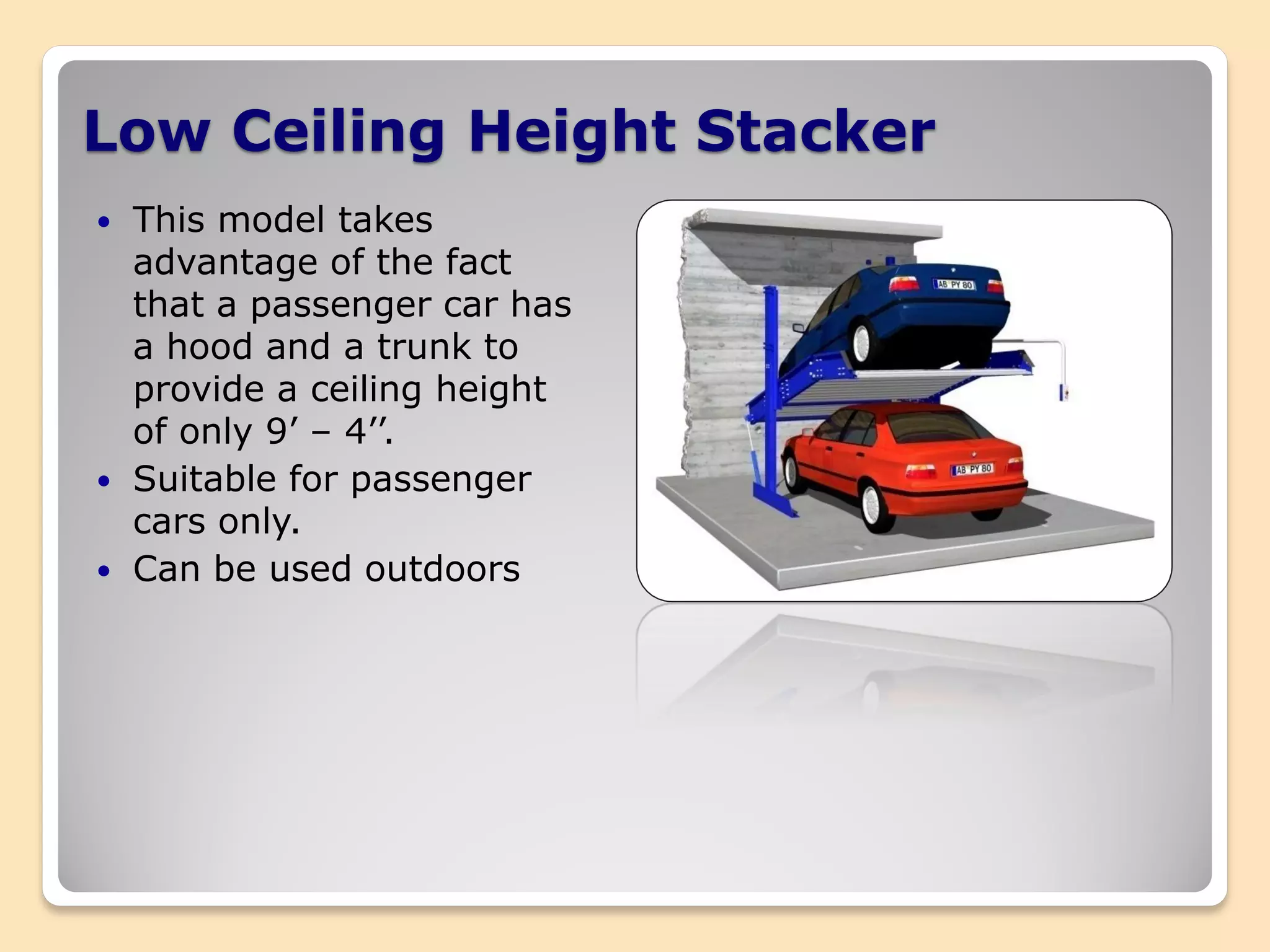

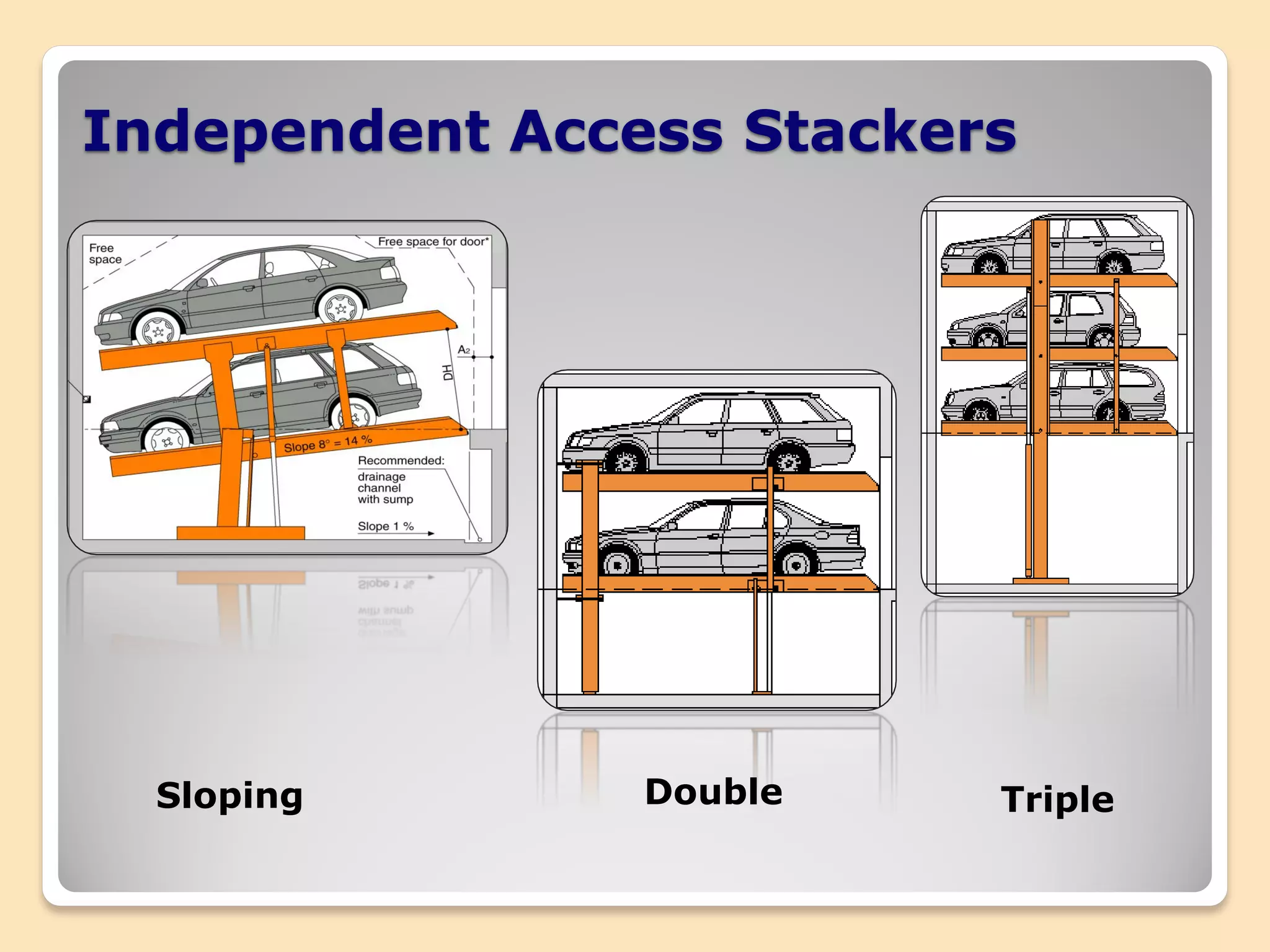

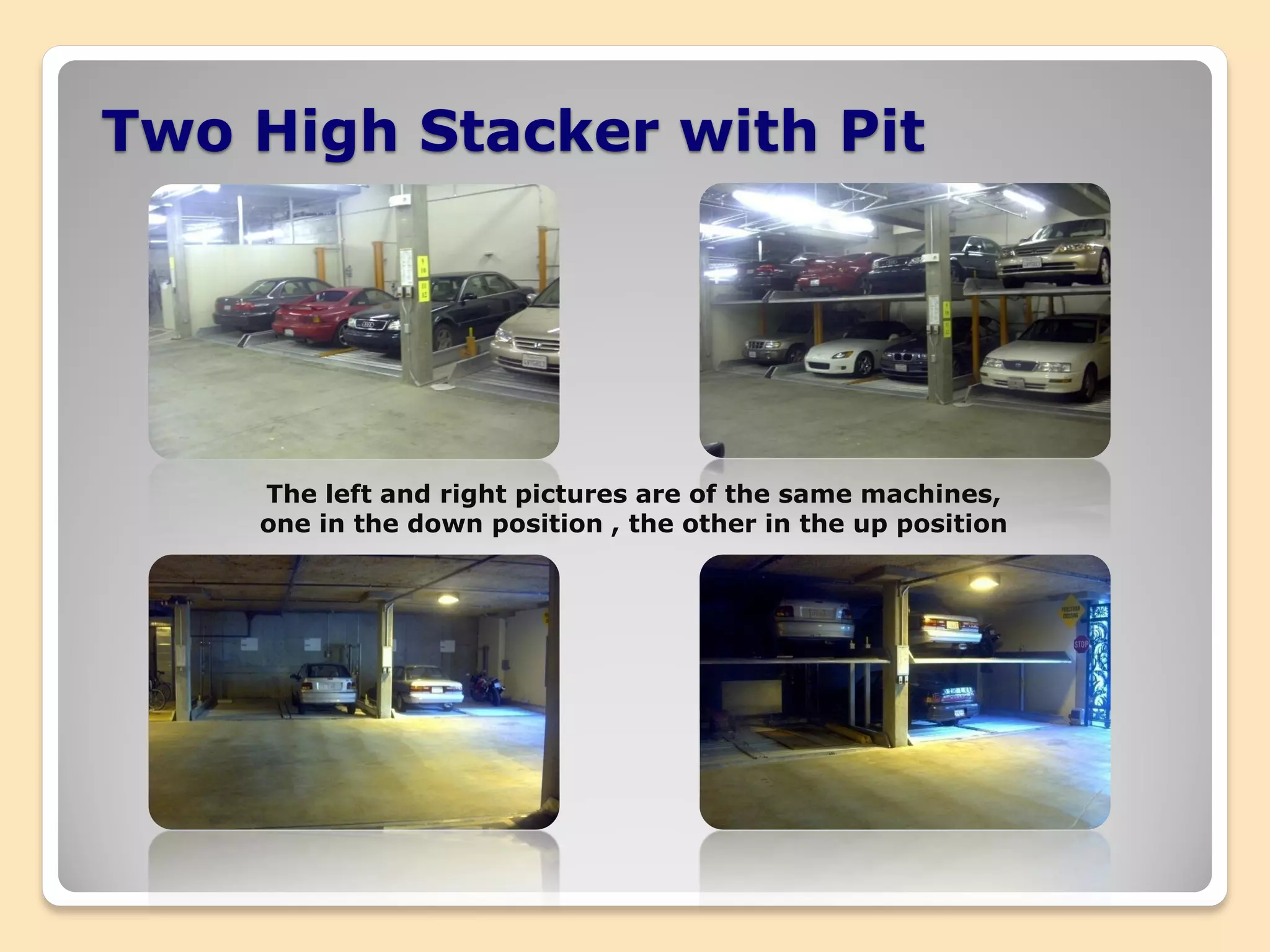

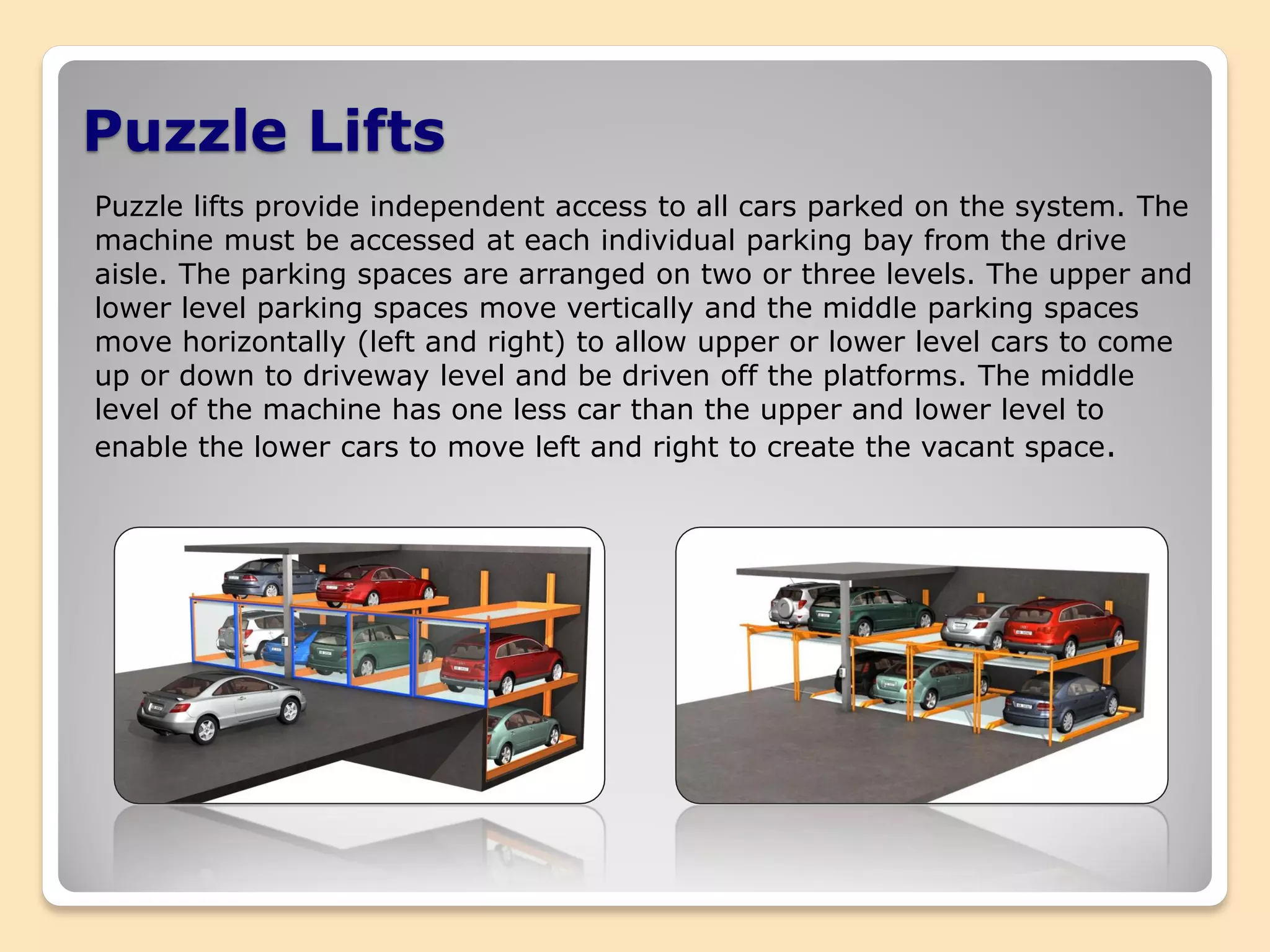

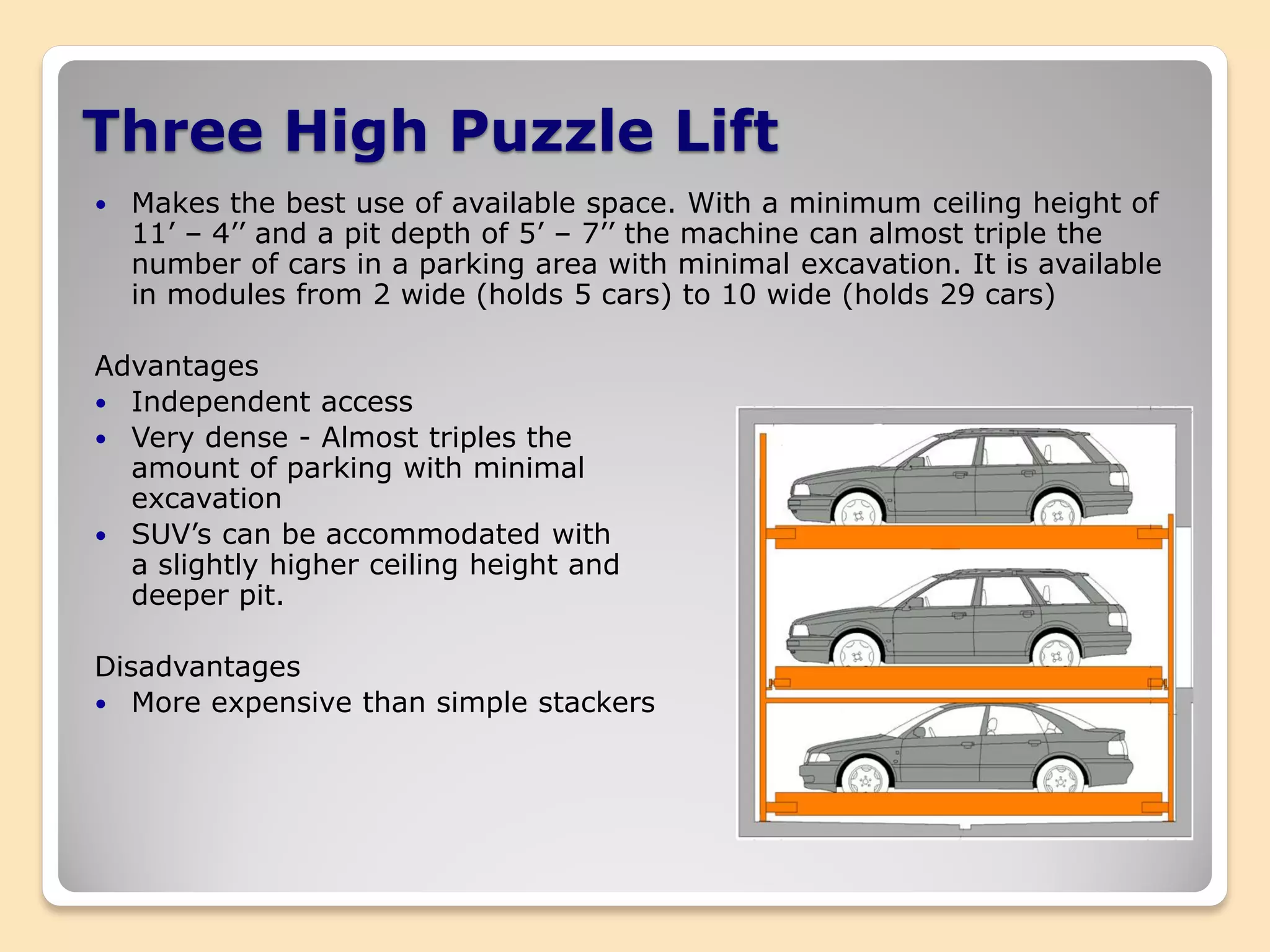

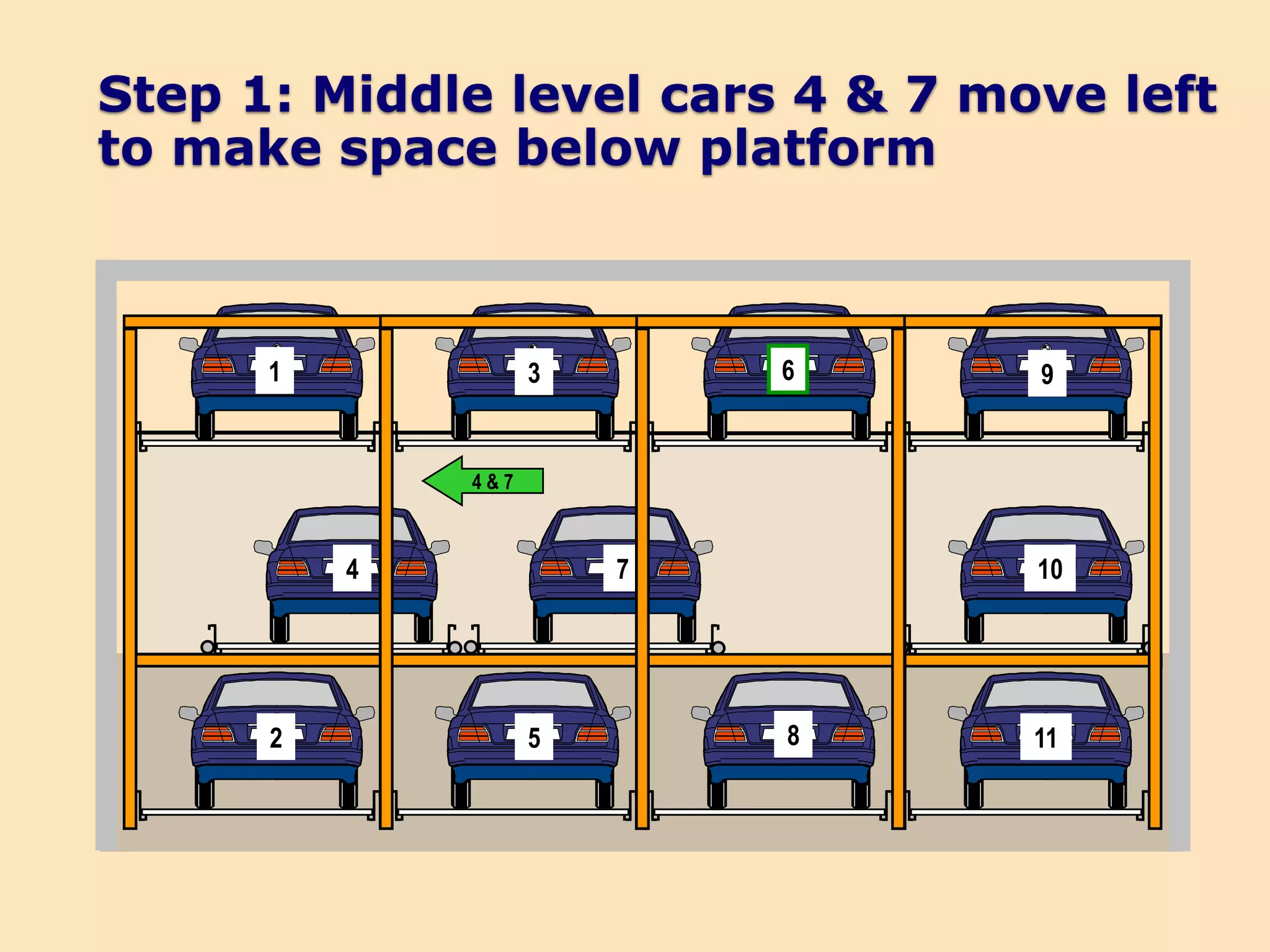

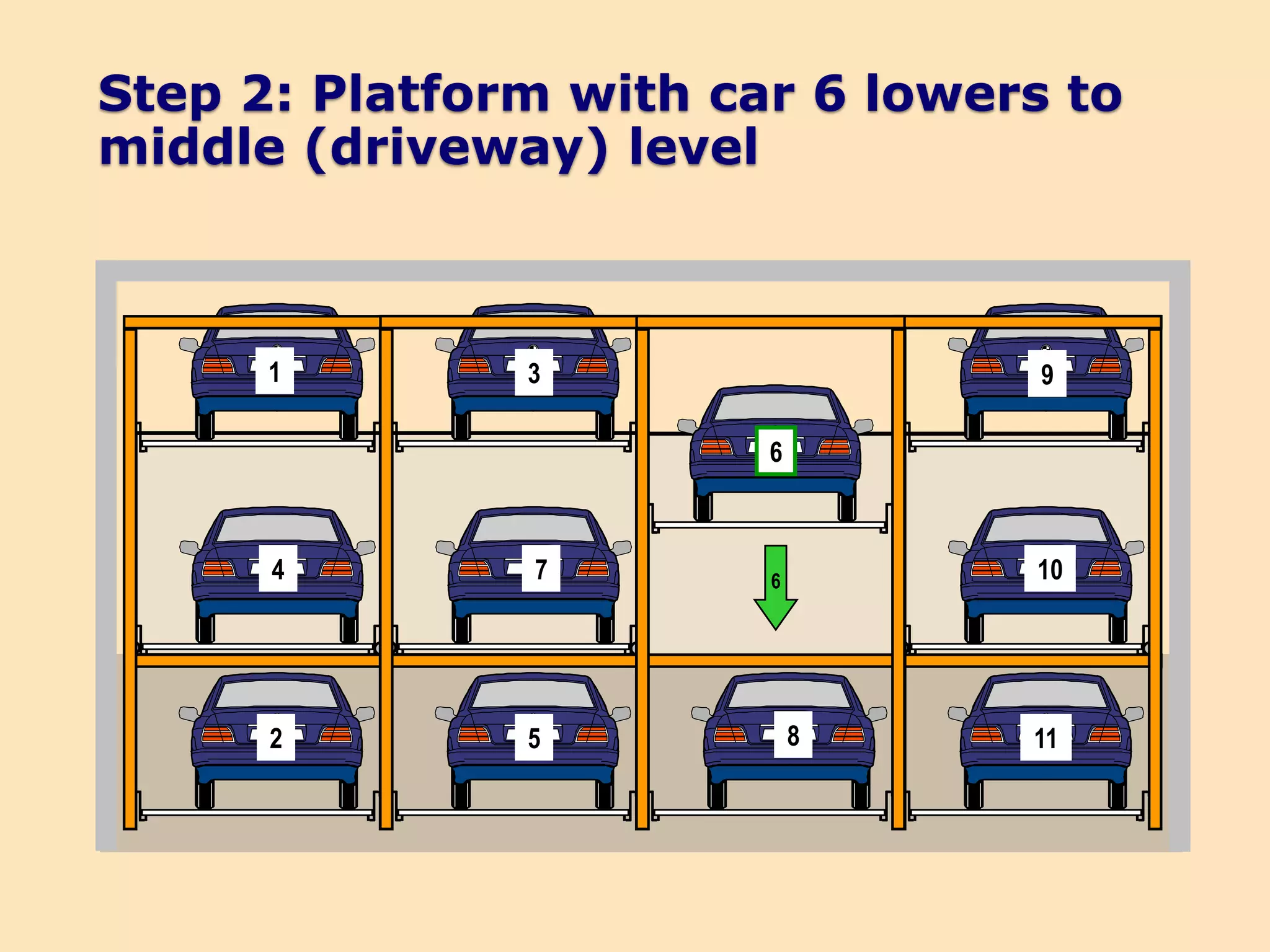

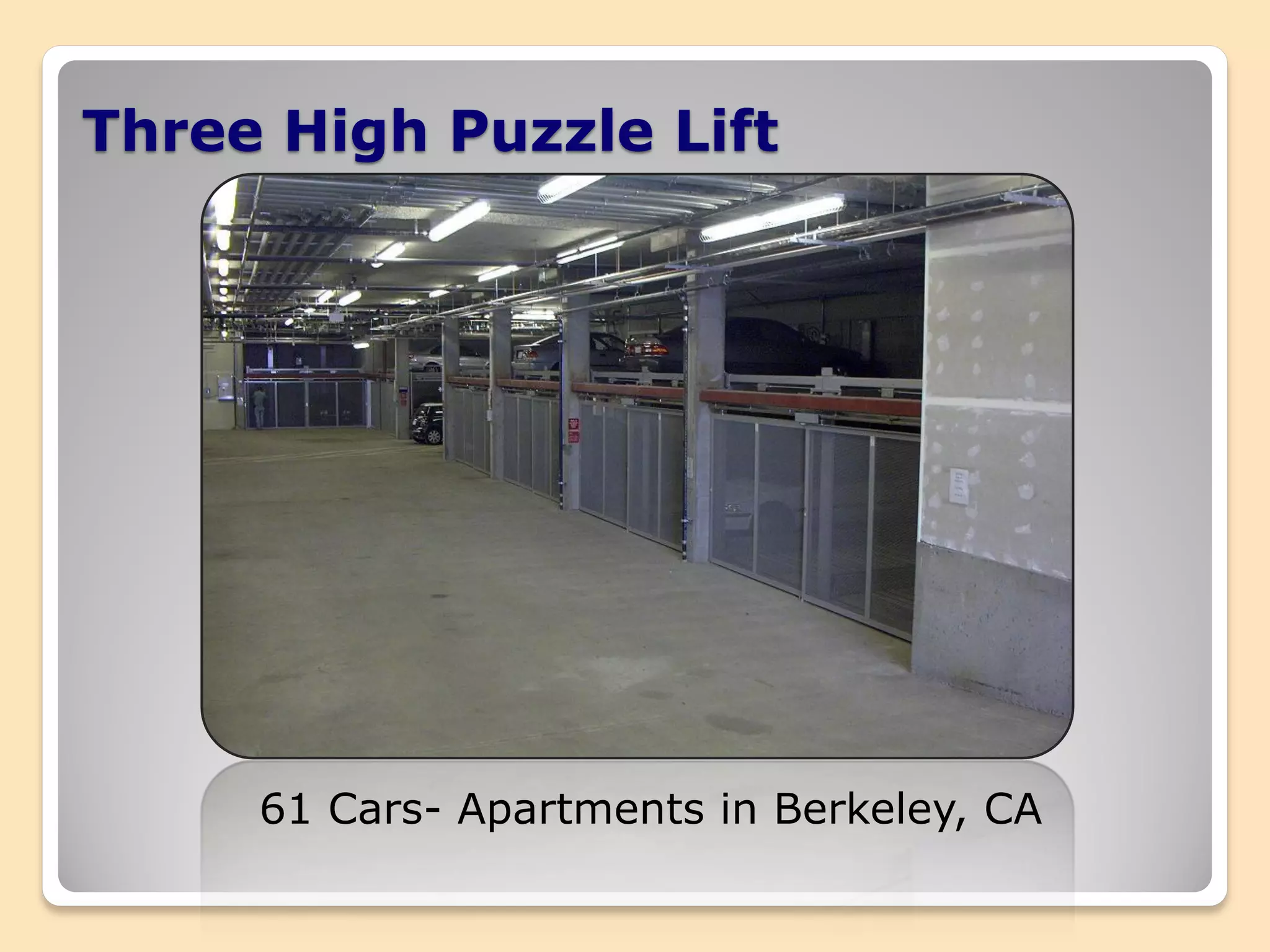

The document discusses various types of mechanical parking solutions that can increase parking density and efficiency. It describes dependent access stackers, independent access stackers, puzzle lifts, and fully automatic parking machines. Dependent access stackers are the most basic, where the bottom car must be moved to access other cars. Independent access stackers use a pit to allow independent access. Puzzle lifts arrange cars on multiple levels and move them horizontally and vertically to provide independent access without a deep pit. Fully automatic machines allow cars to be stored and retrieved from a single access point. The document compares the designs and suitable uses of each type of mechanical parking system.