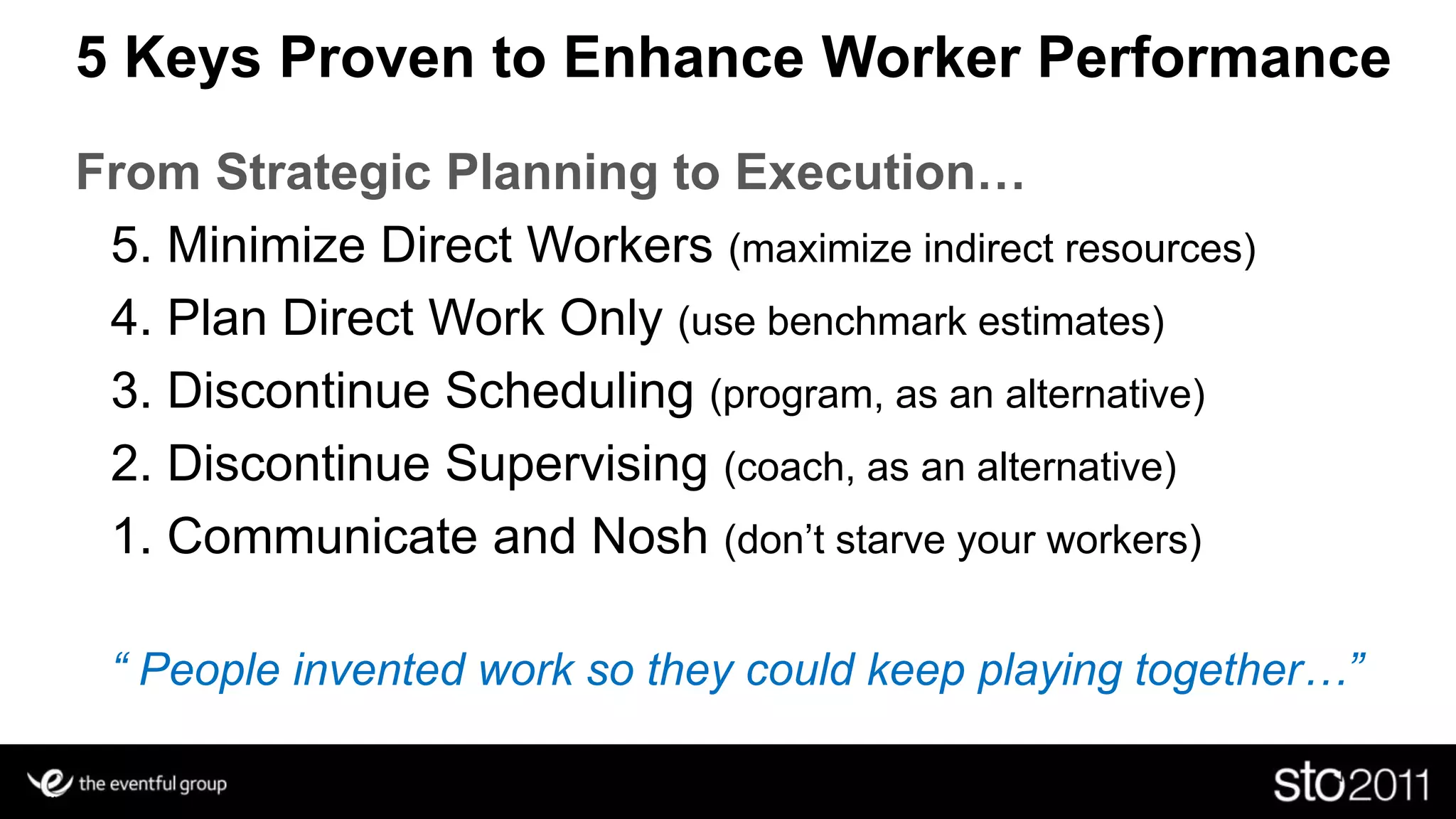

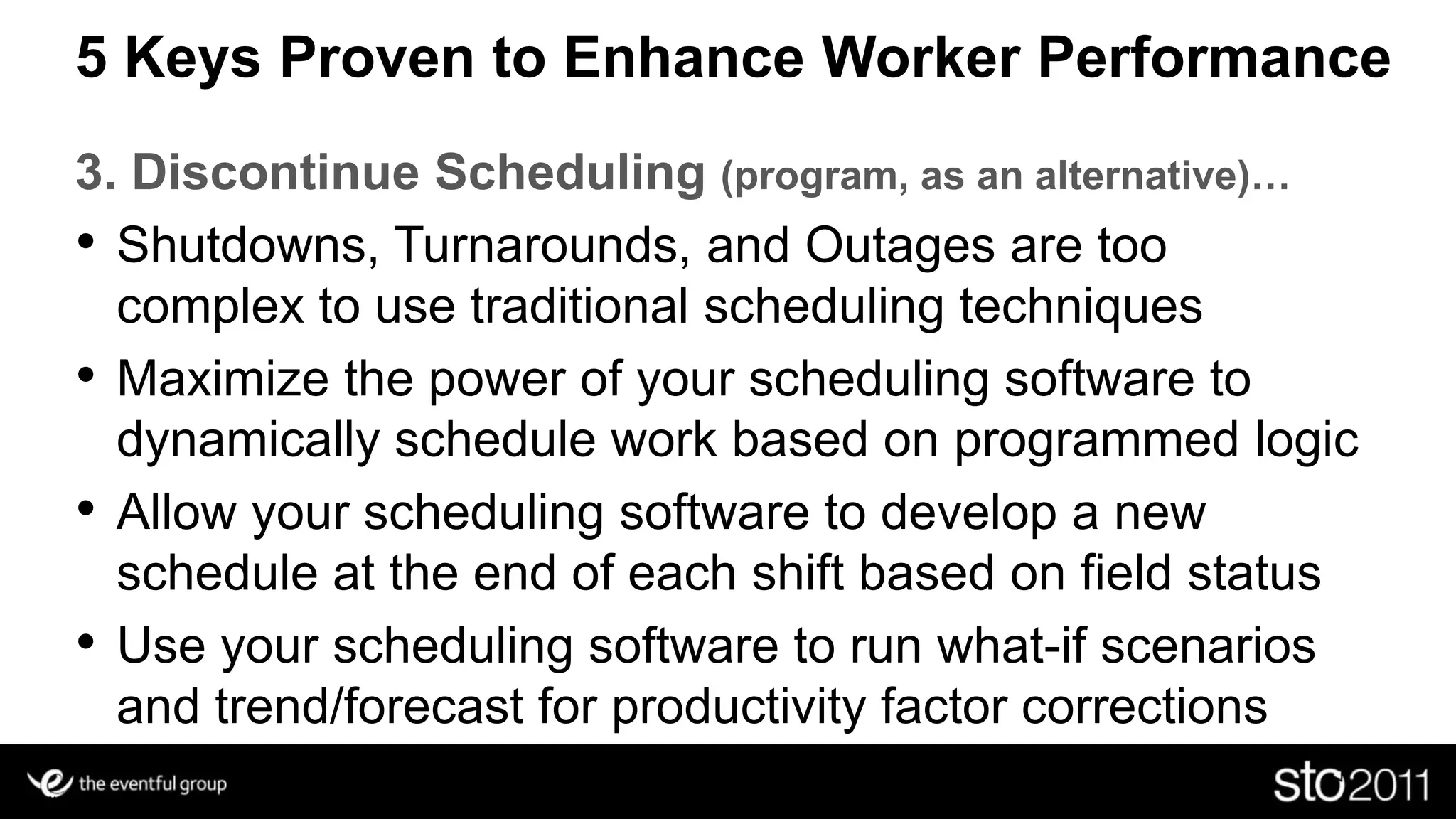

The document outlines 5 keys to enhance worker performance during shutdowns, turnarounds, and outages. The 5 keys are: 1) Communicate and provide nourishment for workers, 2) Coach workers rather than supervise them, 3) Use programming instead of traditional scheduling, 4) Only plan direct work using benchmark estimates, and 5) Minimize direct workers and maximize indirect resources supporting them. The document argues that these strategies can improve worker attitude, safety, efficiency, and project duration by inspiring high performance from knowledgeable, experienced, and willing workers.