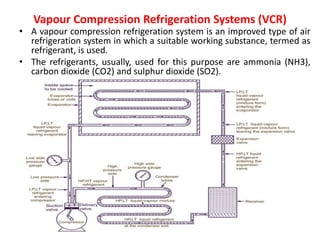

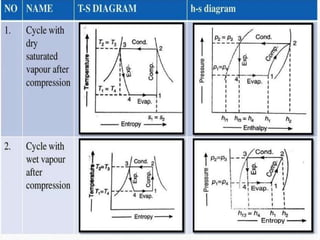

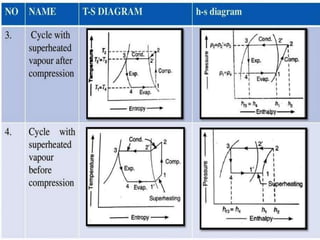

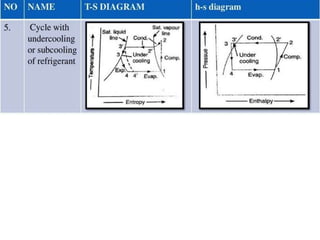

The document discusses the components and types of vapor compression refrigeration systems. It describes the five key components: compressor, condenser, receiver, expansion valve, and evaporator. The compressor increases the refrigerant's pressure and temperature. The condenser cools and condenses the refrigerant. The receiver stores the condensed liquid. The expansion valve reduces the refrigerant's pressure and temperature, causing some evaporation. The evaporator fully evaporates the refrigerant, absorbing heat from its surroundings. There are five types of vapor compression cycles that differ in the state of the refrigerant after compression and condensation.