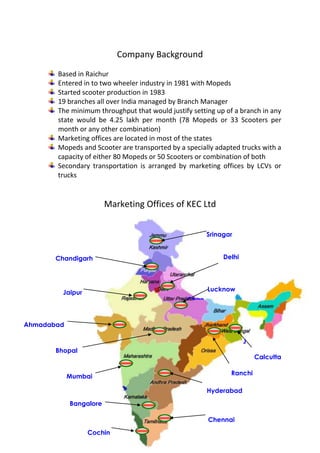

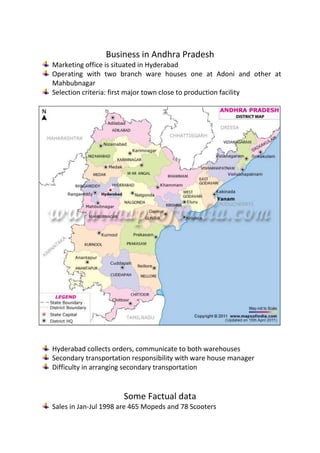

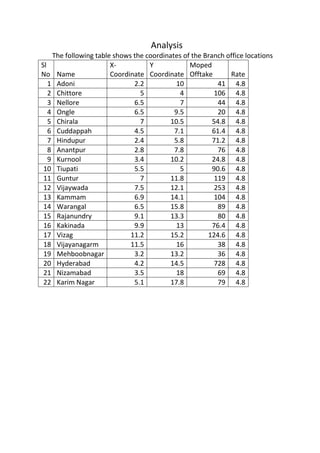

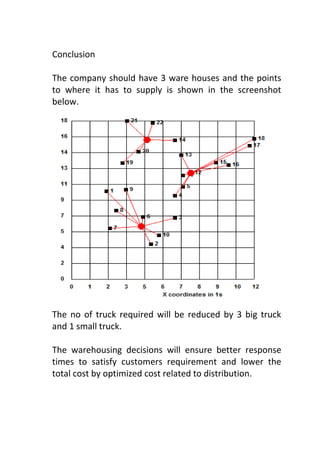

The document discusses logistics and supply chain management for Karnataka Engineering Company. It provides background on the company's operations in India including production facilities, branches, and transportation of products. It then focuses on the company's business in Andhra Pradesh, providing sales data and issues to analyze. The analysis identifies that 3 warehouses are required in Andhra Pradesh based on demand. The optimal locations are near Hyderabad, Vijaywada, and Cuddappah. A new distribution model is proposed that would reduce the number of trucks needed by optimizing routes from the 3 warehouses.