Recommended

PPTX

PPTX

Graphene material for aerospace technology

PDF

Progress in Synthesis of Graphene using CVD, Its Characterization and Challen...

PDF

Graphene: its increasing economic feasibility

DOCX

PPTX

Graphene 140416111416-phpapp02

PDF

Recent development in graphene technology for multidiscilinary properties and...

PPTX

Graphene and its future applications

PDF

631332_2_merged_1423441293

PPTX

PPTX

PPTX

PDF

PDF

PDF

PDF

Graphene materials for opto and electronic applications 2014 Report by Yole D...

PPTX

UG CNSE Capstone Project 2016

PPTX

PDF

EMERGING ENERGY OF GRAPHENE

PPTX

PDF

Graphene is an atomically thin sheet of carbon atoms arranged in a hexagonal ...

PDF

PDF

NOVO MODISMO ACADÊMICO E A PROMESSA DE APLICAÇÃO INDUSTRIAL DE GRAFENO

PPTX

PPT

PPT

GRAPHENE SYNTHESIS AND APPLICATION POSTER

PDF

Graphene -Applications in Electronics

PPTX

PPT

Busi_Law_ttttttttttttttttttttttttttCh11.ppt

PPTX

CAPACITANCeeeeeeeeeeeeeeeeeeeE_II (1).pptx

More Related Content

PPTX

PPTX

Graphene material for aerospace technology

PDF

Progress in Synthesis of Graphene using CVD, Its Characterization and Challen...

PDF

Graphene: its increasing economic feasibility

DOCX

PPTX

Graphene 140416111416-phpapp02

PDF

Recent development in graphene technology for multidiscilinary properties and...

PPTX

Graphene and its future applications

Similar to Kanyai Tapiwa T. graphene Presentation .pptx

PDF

631332_2_merged_1423441293

PPTX

PPTX

PPTX

PDF

PDF

PDF

PDF

Graphene materials for opto and electronic applications 2014 Report by Yole D...

PPTX

UG CNSE Capstone Project 2016

PPTX

PDF

EMERGING ENERGY OF GRAPHENE

PPTX

PDF

Graphene is an atomically thin sheet of carbon atoms arranged in a hexagonal ...

PDF

PDF

NOVO MODISMO ACADÊMICO E A PROMESSA DE APLICAÇÃO INDUSTRIAL DE GRAFENO

PPTX

PPT

PPT

GRAPHENE SYNTHESIS AND APPLICATION POSTER

PDF

Graphene -Applications in Electronics

PPTX

More from tapce1

PPT

Busi_Law_ttttttttttttttttttttttttttCh11.ppt

PPTX

CAPACITANCeeeeeeeeeeeeeeeeeeeE_II (1).pptx

PPT

mel705554444444444444444444444445-19.ppt

PPTX

Notes_240419_18888888888888888890217.pptx

PPTX

Zero-Order Instruments notes by kanyai tt.pptx

PPTX

GaN Blue Laser Diodes by kanyai tt .pptx

PPT

ORGIMP Block 1-3 International Standards_2012.ppt

PPT

ORGIMP Block 1-2 Need for a Regulatory Program_2012.ppt

PPT

Scheming a HRE TP workshop presentation .ppt

PPTX

STATIONARY WAVES on waves that will help.pptx

PPTX

STANDARD OF DRESS kkkkkkkkkkjkjk2014.pptx

PPTX

PHOTOSYNTHESIS the manufacturer of food.pptx

PPTX

Zero-Order Instruments Kanyai Tapiwa T.pptx

PPTX

Kanyai Tapiwa T. graphene a presentation .pptx

PPTX

Zero-Order Instruments Kanyai Tapiwa T.pptx

PPTX

Step and ramp response of first and second order instruments_MUWUSHA Rumbidza...

PPTX

Transfer Function_Clive K. Chigambure (R9917101)-1.pptx

PPTX

Step and ramp response of first and second order instruments_MUWUSHA Rumbidza...

PPTX

Transfer Function_Clive K. Chigambure (R9917101)-1.pptx

PPTX

Enterprenuership Lesson that help 1.pptx

Recently uploaded

PPTX

Central Line Associated Bloodstream Infection

PDF

Beak Modifications by Dr. Ramzan Virani pptx.pdf

PPTX

Definition of communication skills and it's process.

PPTX

Day 2 ppt english.powerpoint presentation ppt

PPTX

West Hatch High School - GCSE Media Studies

PPTX

literary theory and criticism by Vivek p

PPTX

COMMUNICATION ITS PROCESS ELEMENTS & BARRIER .pptx

PPTX

Payment Follow-Up via WhatsApp in Odoo 18.1 Accounting

PPTX

Powerpoint for testing in embed test with Sway

PDF

Aminoglycosides.pdf for B.Pharmacy Medicinal Chemistry-III (BP601T), GPAT, a...

PPTX

TLE 8 W1 Q4 D2.pptx COMMON FLOOR PLAN SYMBOLS PLUMBING SYMBOLS

PPTX

The night at deoli - Ruskin bond's story of first love

PPTX

West Hatch High School - GCSE Art Presentation

PPTX

Poster Based Ethical Reflection - Dharma and Values Poster.pptx

PPTX

West Hatch High School: Year 9 Art Course

PPTX

PREVENTIVE PEDIATRICS.pptx

PDF

Bishan_Singh_Presentation - Toba tek Singh

PDF

Darwinism: Theory of Natural Selection and Origin of Species

PDF

U.S. Departments of Education and Treasury fact sheet

PPTX

'Colonial Mentality and Social Identity in Karma by Khushwant Singh'

Kanyai Tapiwa T. graphene Presentation .pptx 1. University of Zimbabwe

Dept of Space Science and Applied Physics

Overcoming Graphene’s Transistor Fidelity Gap :

From Lab Breakthroughs to Market Realities

Presenter: Kanyai TT

BY KANYA TT(Msc APPLIED PHYSICS)

2. Objectives

Evaluate synthesis methods for transistor-grade graphene.

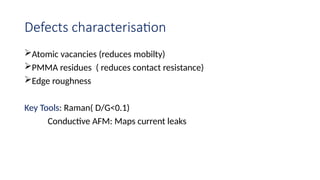

Quantify defect impacts on mobility and on/off ratios.

Propose bandgap engineering strategies for digital logic.

Develop a cost-scaling roadmap for industrial adoption.

3. Introduction

Why Graphene?

Properties

Strength: 200x steel

• Conductivity: 10⁶ S/cm

• Flexibility: <1% strain resistance.

Applications

Flexible displays (Samsung prototype)

Ultra-fast transistors (IBM),

solid-state batteries (Nanotech Energy).

Key Challenge

Bandgap absence and transfer defects limit transistor switching fidelity.

4. Literature Review

Timeline of Innovations (2020–2025)

• 2022: CVD scalability improved (wafer-scale growth, 80% yield).

• 2023: Laser lift-off (GLLO) reduces transfer residues by 90%.

• 2024: Hybrid Sb₂O₃ dielectric integration enhances interface quality.

• 2025: Biomass-derived graphene enters sports equipment market (50% cost

reduction).

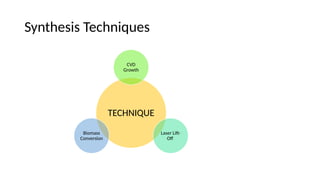

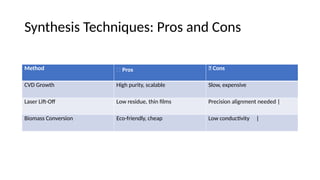

5. 6. 7. Synthesis Techniques: Pros and Cons

Method ✅ Pros ❌ Cons

CVD Growth High purity, scalable Slow, expensive

Laser Lift-Off Low residue, thin films Precision alignment needed |

Biomass Conversion Eco-friendly, cheap Low conductivity |

8. Why this Research Matters

Defect impact

• Simulation show 0.1% vacancies which implies 50% reduction in

mobility

Cost projection

• Model 300mm wafer costs will drop to $500 2030 if CVD yield

improves by 65%

Thermal limit

• COMSOL analysis found graphene transistors overheat at 1mA/μm

9. 10. 11. 12. 13. 14. 15. References

Lee, J. et al. (2024). GLLO for Ultrathin Devices. Nature Electronics.

Graphenea. (2025). Market Barriers Report

IndustryARC. (2025). Graphene Market Forecast.