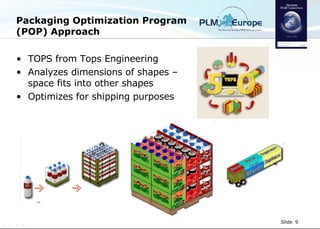

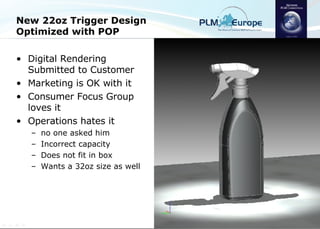

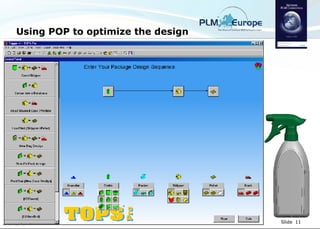

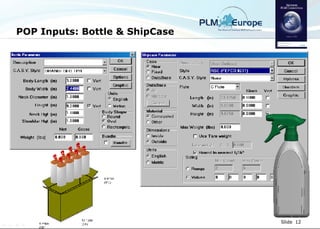

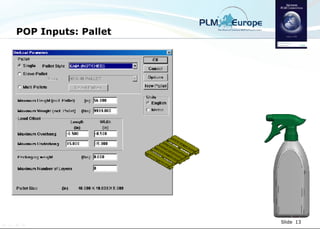

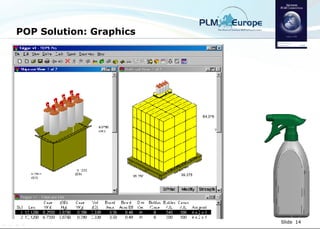

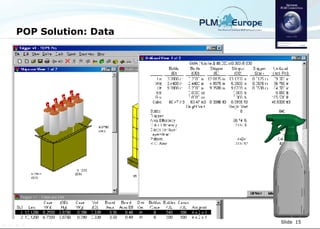

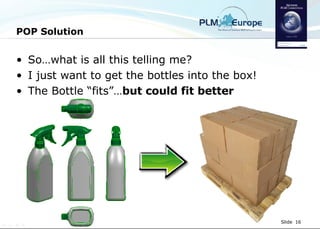

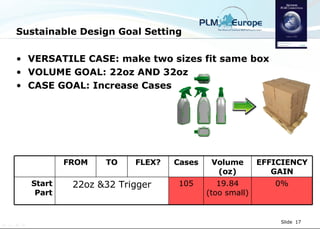

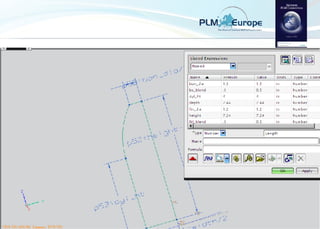

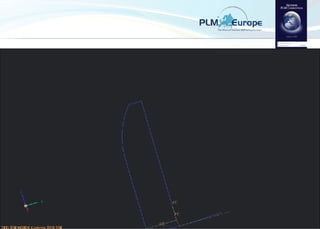

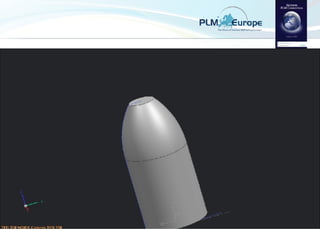

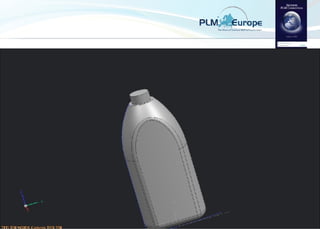

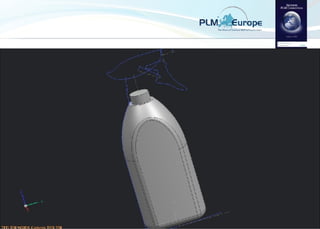

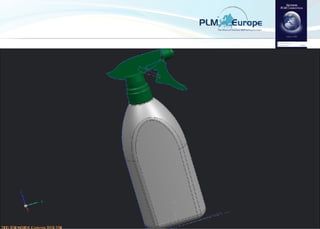

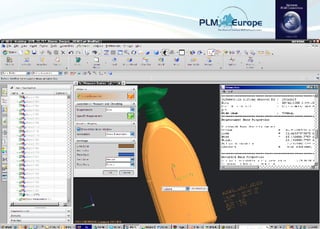

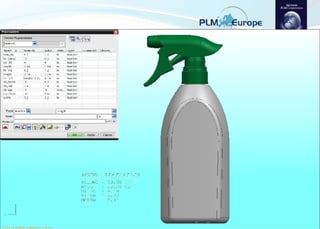

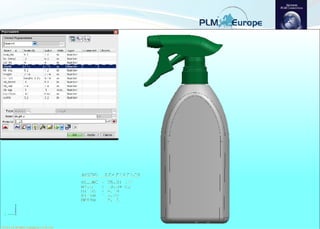

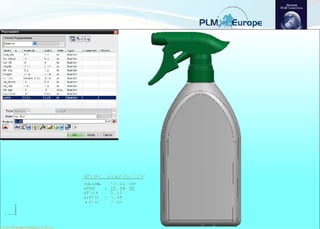

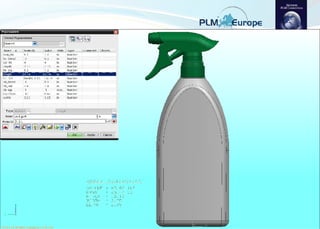

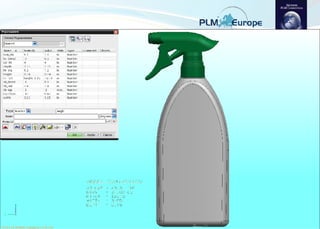

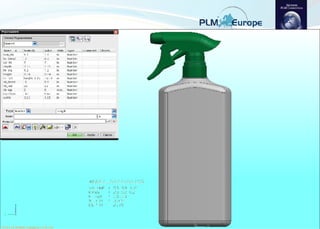

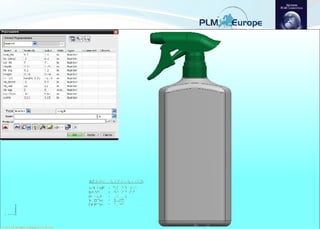

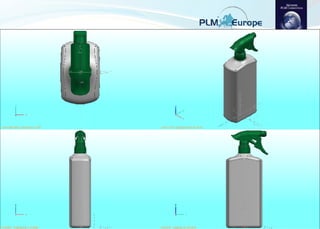

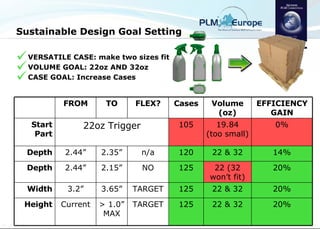

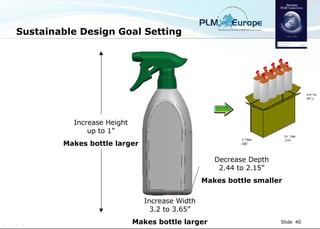

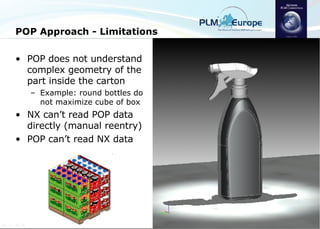

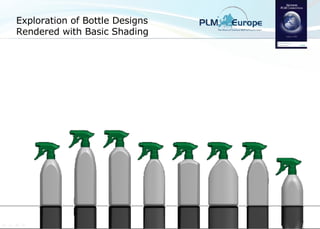

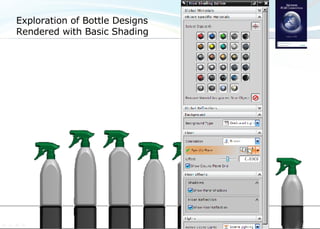

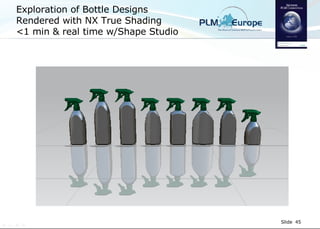

The document discusses the development of sustainable packaging by Consolidated Container Company, focusing on a case study involving a trigger sprayer bottle redesign to improve fitting in shipping containers. It explores the use of a Packaging Optimization Program (POP) and NX software tools to create efficient designs that meet performance, environmental, and economic criteria. The presentation highlights collaboration and challenges in optimizing bottle dimensions while addressing sustainability goals.

![Developing Sustainable Packaging using NX John Manderfield Director of Creative Design Consolidated Container Company [email_address]](https://image.slidesharecdn.com/cccplme08v4a-manderfield-1223984497938999-9/75/John-Manderfield-Using-NX-6-for-Sustainable-Packaging-1-2048.jpg)