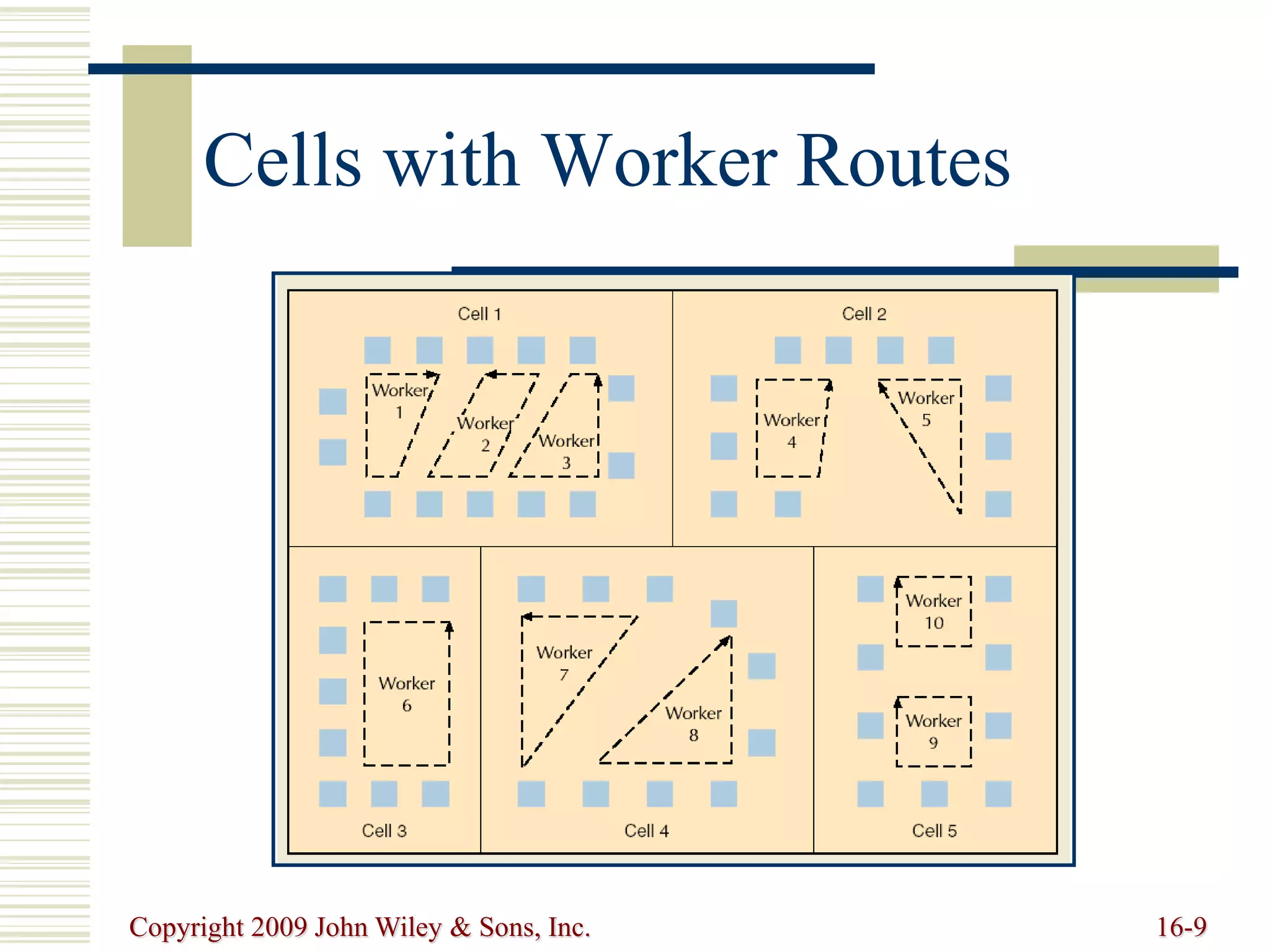

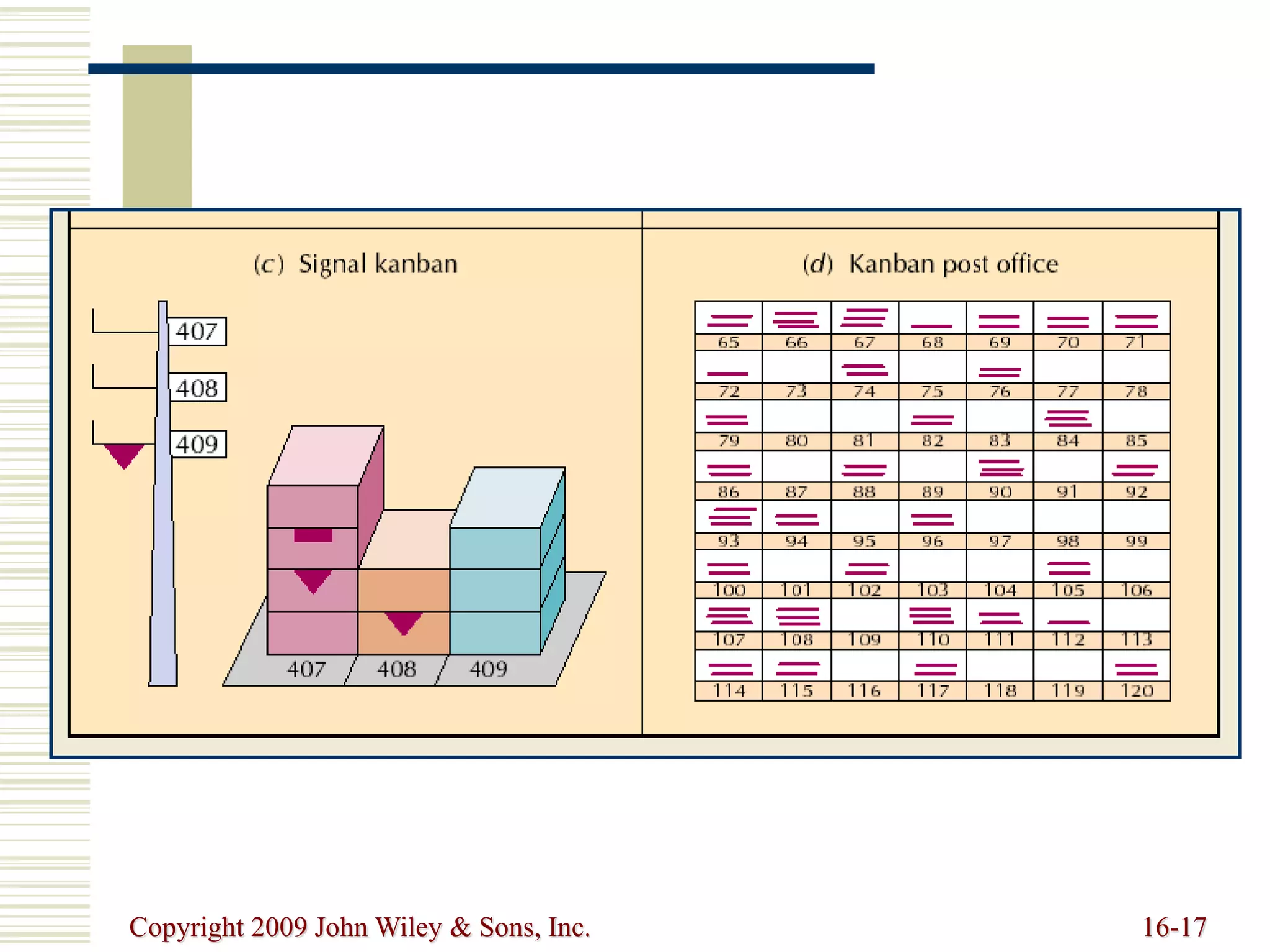

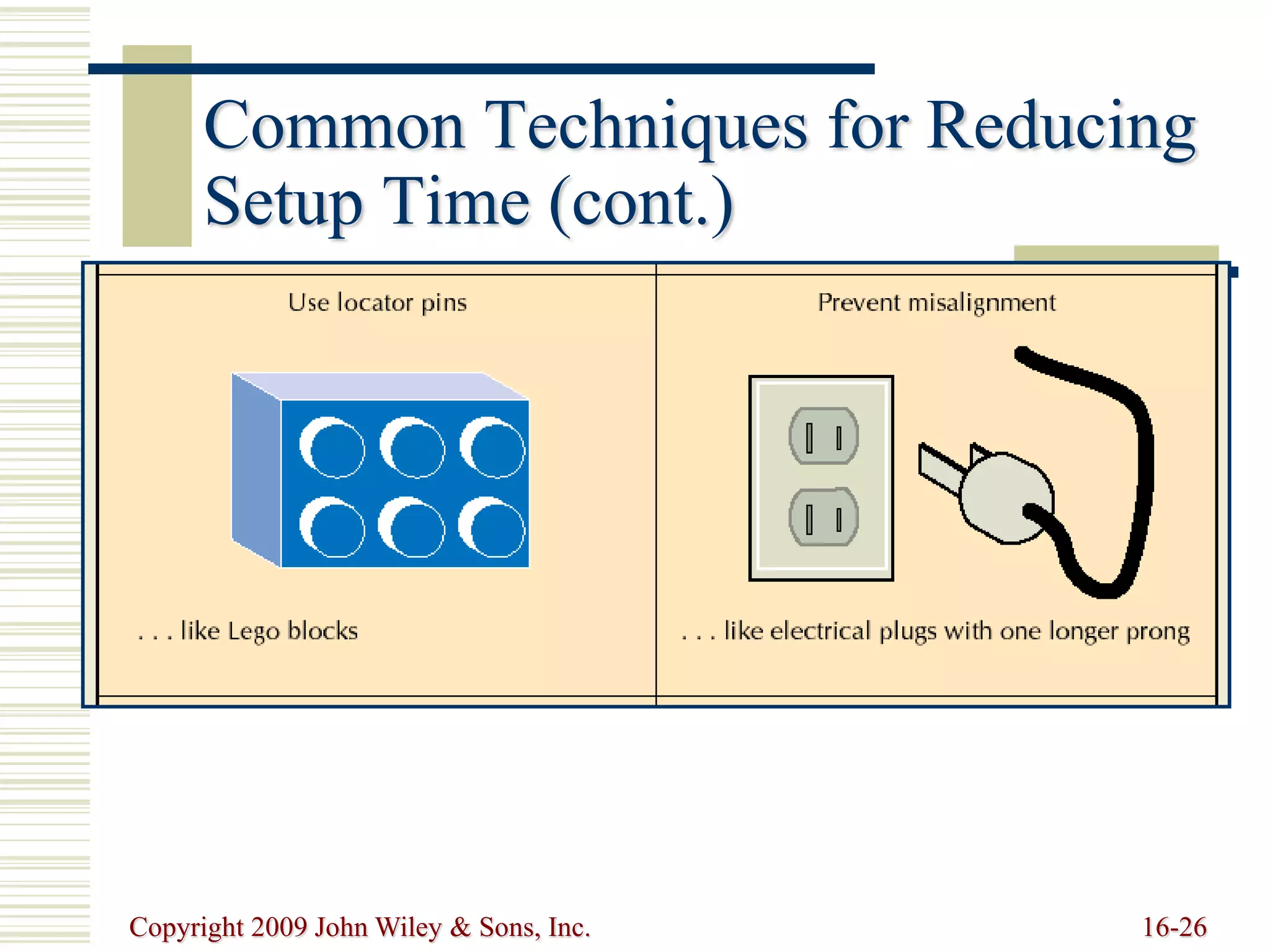

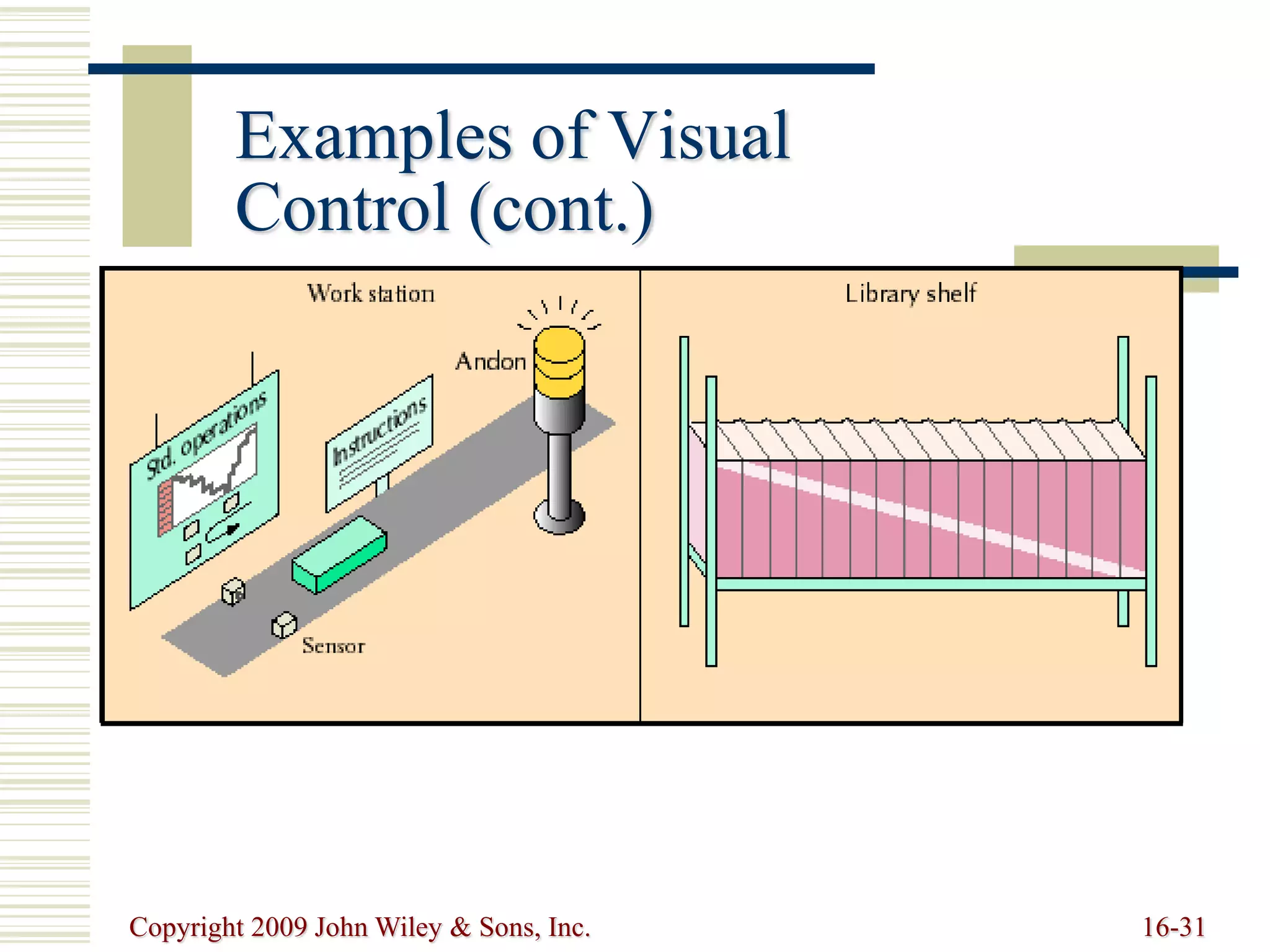

The document discusses the principles and techniques of lean production systems. It defines lean production as doing more with less inventory, fewer workers, and less space. The basic elements of lean include flexible resources, cellular layouts, pull systems using kanbans, small lot sizes, quick changeovers, uniform production levels, quality control at the source, total productive maintenance, and developed supplier networks. The goals are to eliminate waste and smooth production flow through techniques like just-in-time delivery, continuous improvement, and visual management systems.