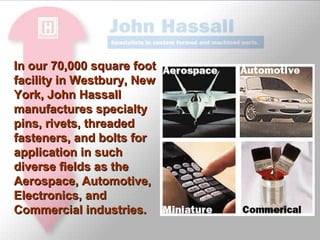

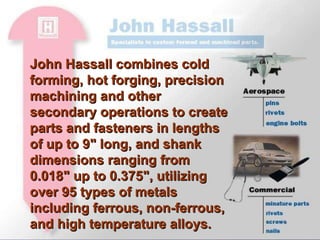

John Hassall, Inc. was founded in 1850 in New York City and developed one of the earliest coil fed nail producing machines in the United States, later expanding into commercial nail production and producing cold formed rivets and parts for the military during World War I. Today, John Hassall manufactures specialty fasteners for aerospace, automotive, electronics, and other industries at its 70,000 square foot facility in Westbury, New York, implementing continuous improvement programs to meet customer needs and expectations.