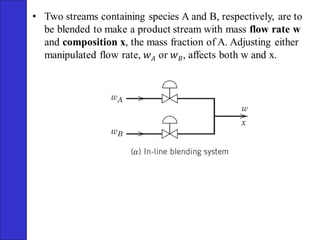

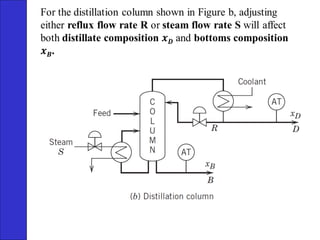

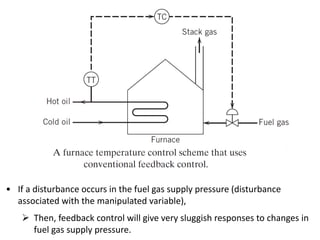

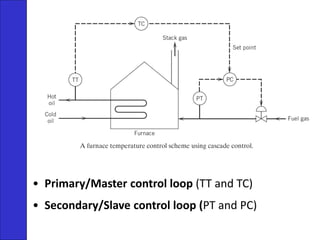

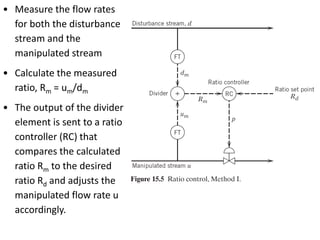

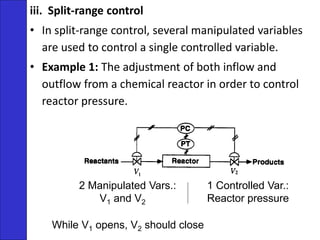

The document covers advanced control strategies in instrumentation and process control, focusing on multi-loop control, cascade control, ratio control, and split-range control. It describes how these methods manage multiple input-output relationships, improve system responsiveness to disturbances, and maintain specified ratios or controlled variables. Additionally, it distinguishes between servo and regulator problems, addressing system behavior under set-point changes and varying disturbances.