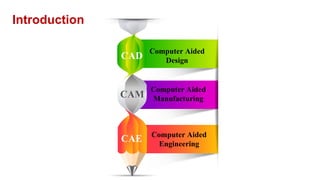

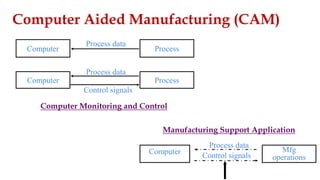

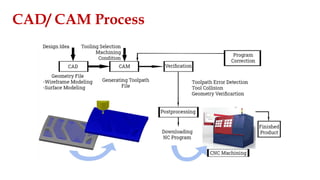

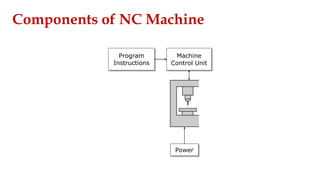

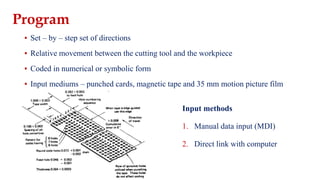

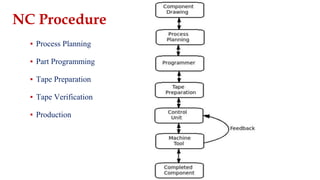

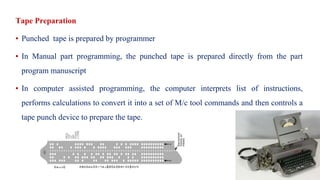

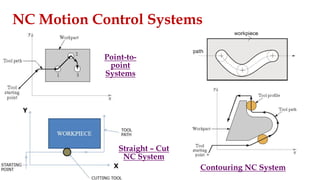

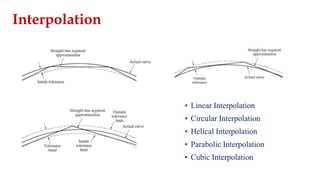

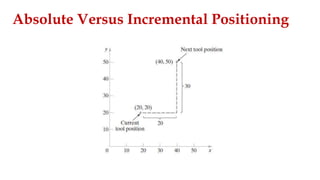

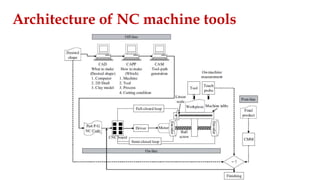

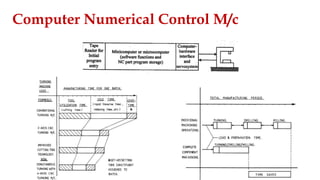

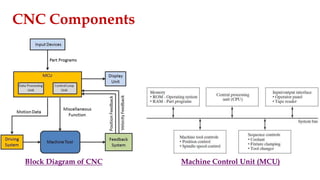

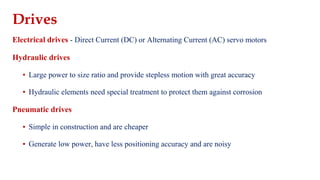

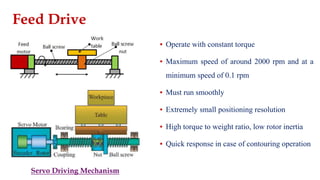

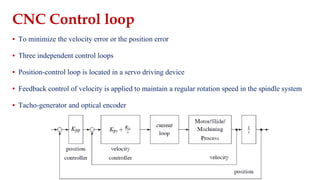

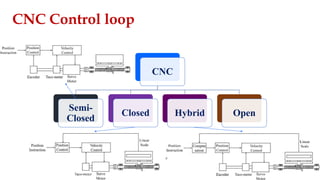

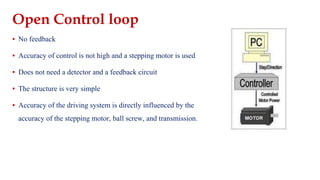

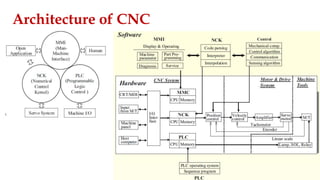

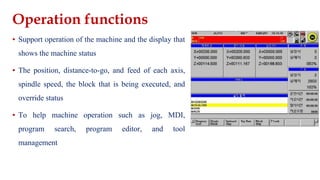

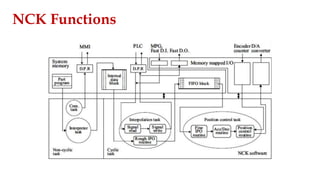

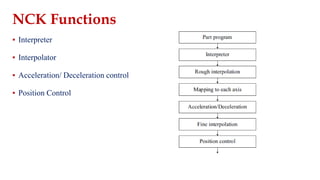

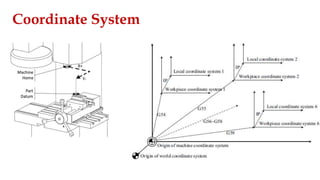

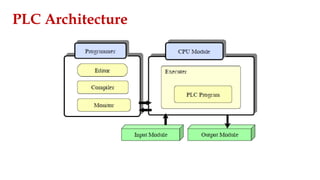

The document discusses CNC programming and numerical control. It begins by explaining CAD, CAM, and CAE systems and how they integrate with computer-aided design. Numerical control and the components of NC machines are then described, including the machine, control unit, and programming. The document outlines the NC programming process and discusses point-to-point and contouring NC systems. It also covers CNC machines, their components, control loops, and architecture. Finally, it provides an overview of programmable logic controllers and their functions.