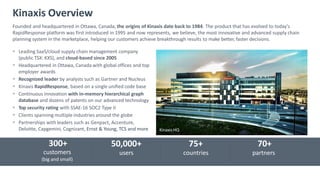

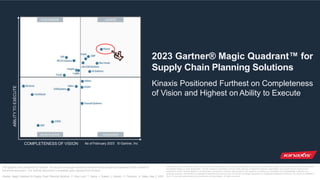

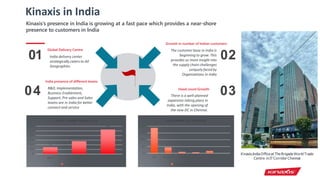

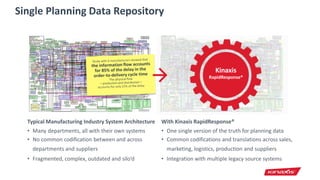

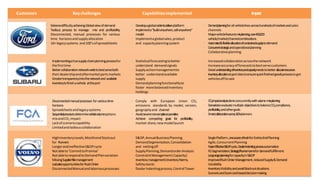

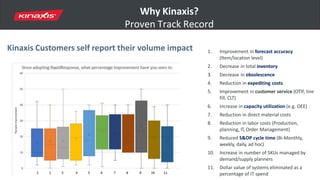

Kinaxis, a leading SaaS supply chain management company founded in Canada, provides the RapidResponse platform for advanced supply chain planning solutions. The platform integrates multiple data sources to improve decision-making and operational efficiency across various industries. With a growing presence in India and a significant number of global partnerships and clients, Kinaxis focuses on continuous innovation and unmatched technology to address complex supply chain challenges.