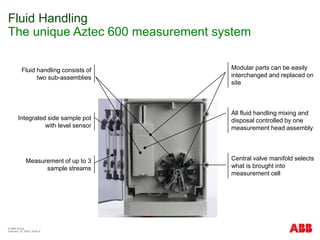

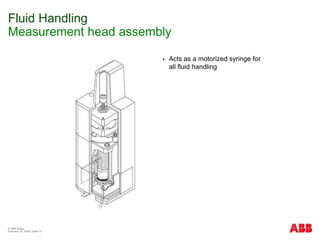

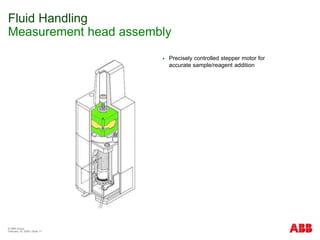

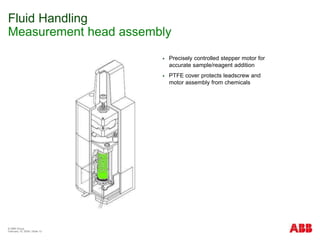

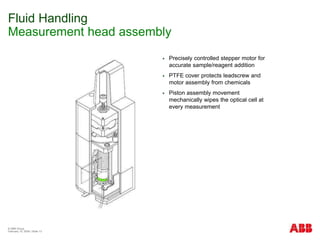

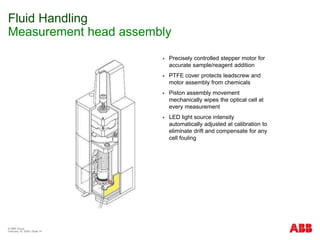

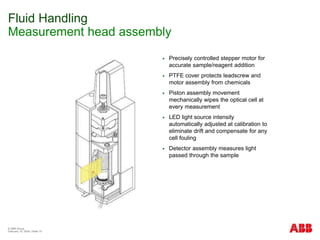

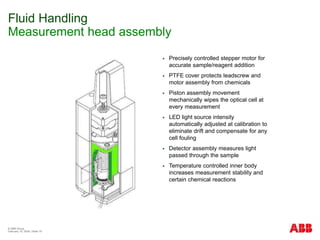

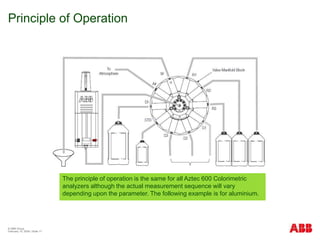

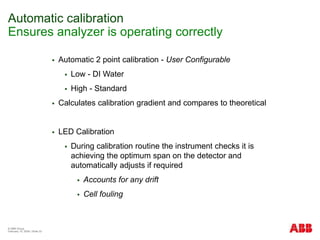

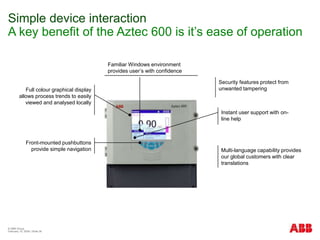

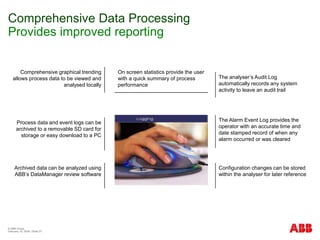

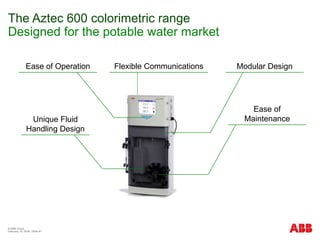

The document introduces ABB's new Aztec 600 colorimetric range of online water analyzers. The Aztec 600 offers a compact, reliable and easy-to-use solution for monitoring multiple water quality parameters. It uses a common fluid handling and measurement design that allows for simple operation, maintenance and switching of parameters. The analyzer provides accurate and flexible monitoring to help water utilities optimize their treatment processes.