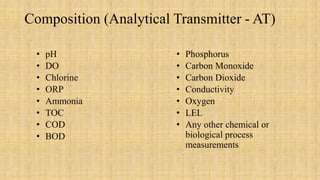

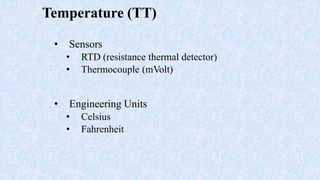

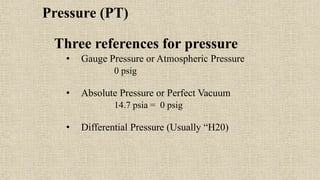

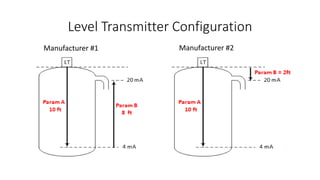

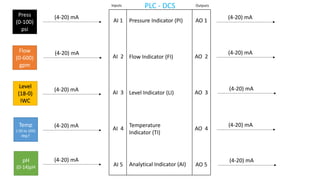

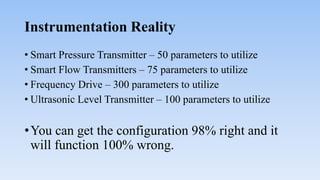

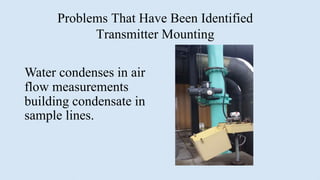

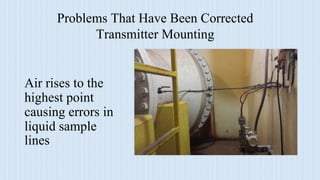

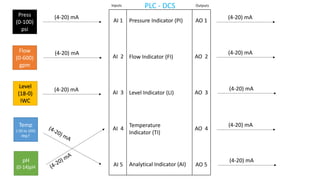

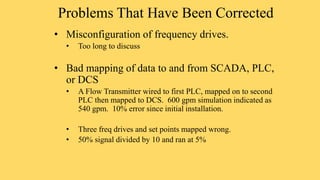

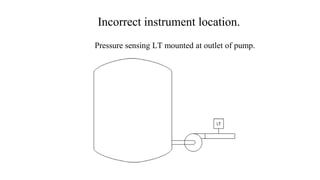

This document discusses instrumentation and process control. It covers five main processes that are commonly controlled: temperature, pressure, flow, level, and composition. For each process it discusses the types of sensors used to measure the process variable as well as common engineering units. It also provides examples of how these processes are controlled in applications like engines. The document emphasizes the importance of proper instrument installation and configuration to avoid errors in measurement. It recommends validation of instrumentation and control schemes to ensure accurate data and system operation.