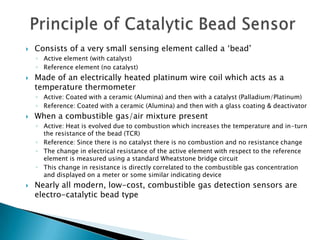

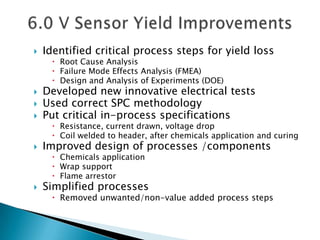

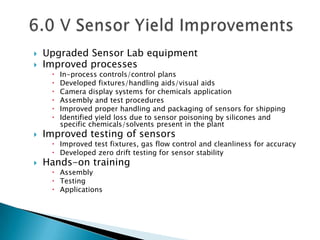

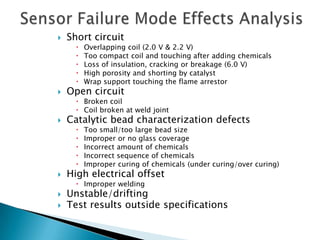

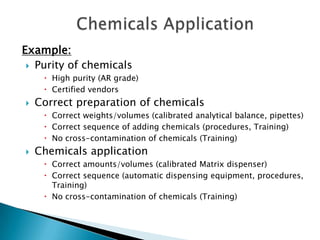

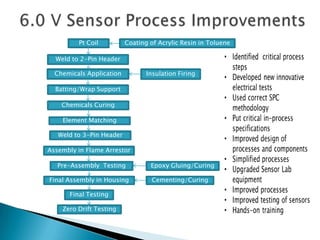

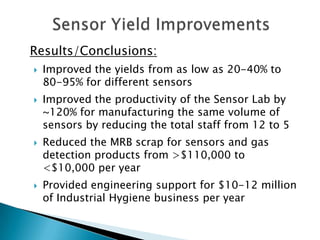

The document summarizes efforts to improve production yields for catalytic bead gas sensors from 20-40% to 80-95% after the manufacturing process was moved. Critical process steps were identified and improved through tools like root cause analysis and design of experiments. Process upgrades like chemical application methods and quality controls helped address defects. Testing procedures were enhanced and hands-on training provided. The changes reduced scrap and improved productivity while supporting $10-12M in annual business.