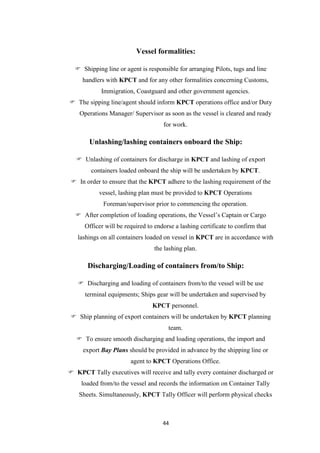

The document provides an overview of Krishnapatnam Port Container Terminal in India. It details the background of container shipping and Krishnapatnam Port. The port aims to be India's largest gateway on the east coast with world-class infrastructure, high productivity, and unrivaled customer service. The document outlines the port's facilities, equipment, location, corporate profile, management team, vision, and some key milestones.