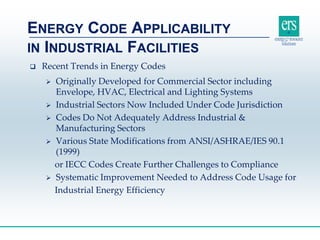

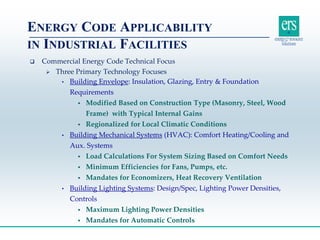

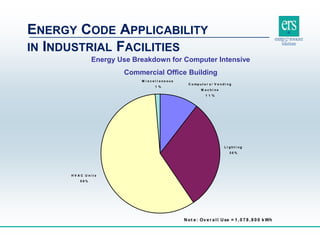

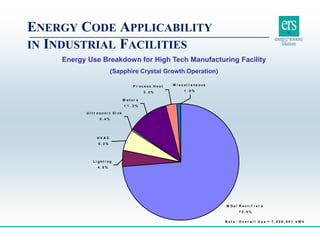

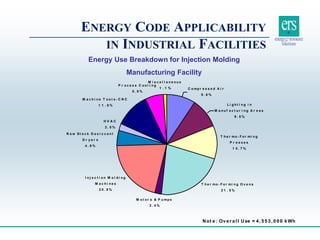

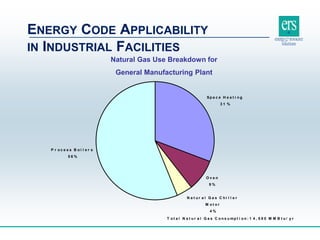

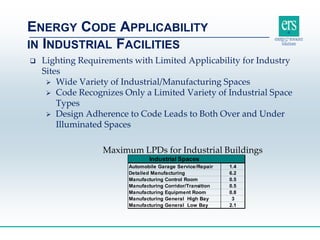

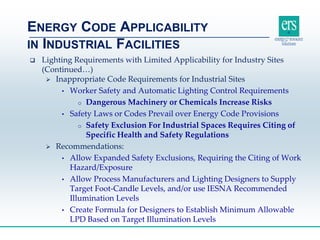

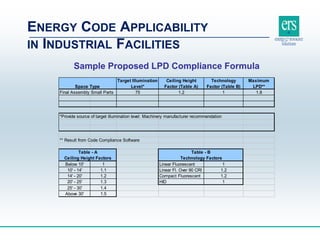

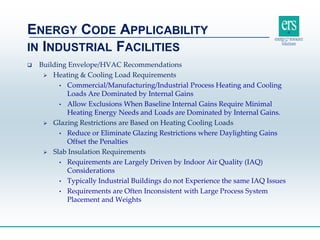

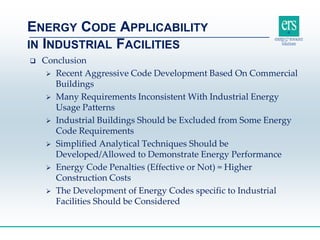

This document discusses the challenges with applying commercial building energy codes to industrial facilities. It notes that industrial buildings have very different energy usage profiles than commercial buildings, with process loads often dominating. The document examines some specific issues industrial buildings face in meeting requirements around lighting power densities, envelope insulation, and HVAC that are designed for commercial buildings. It recommends allowing more flexibility and safety exclusions for industrial spaces, as well as developing simplified methods and potential separate energy codes tailored specifically for industrial facilities.