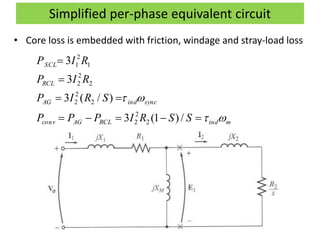

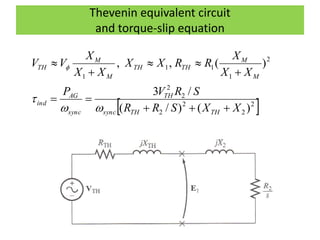

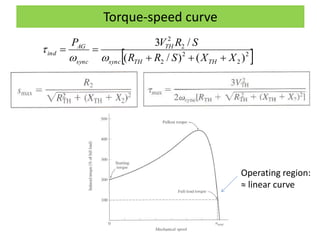

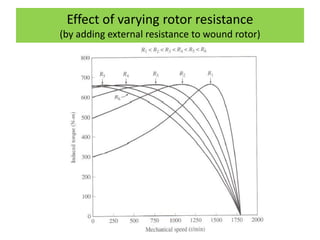

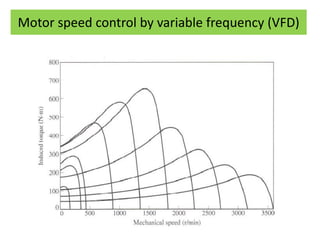

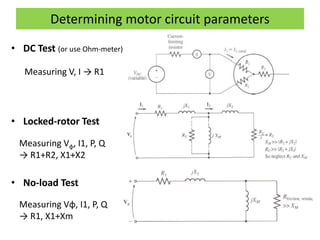

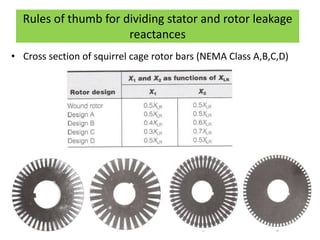

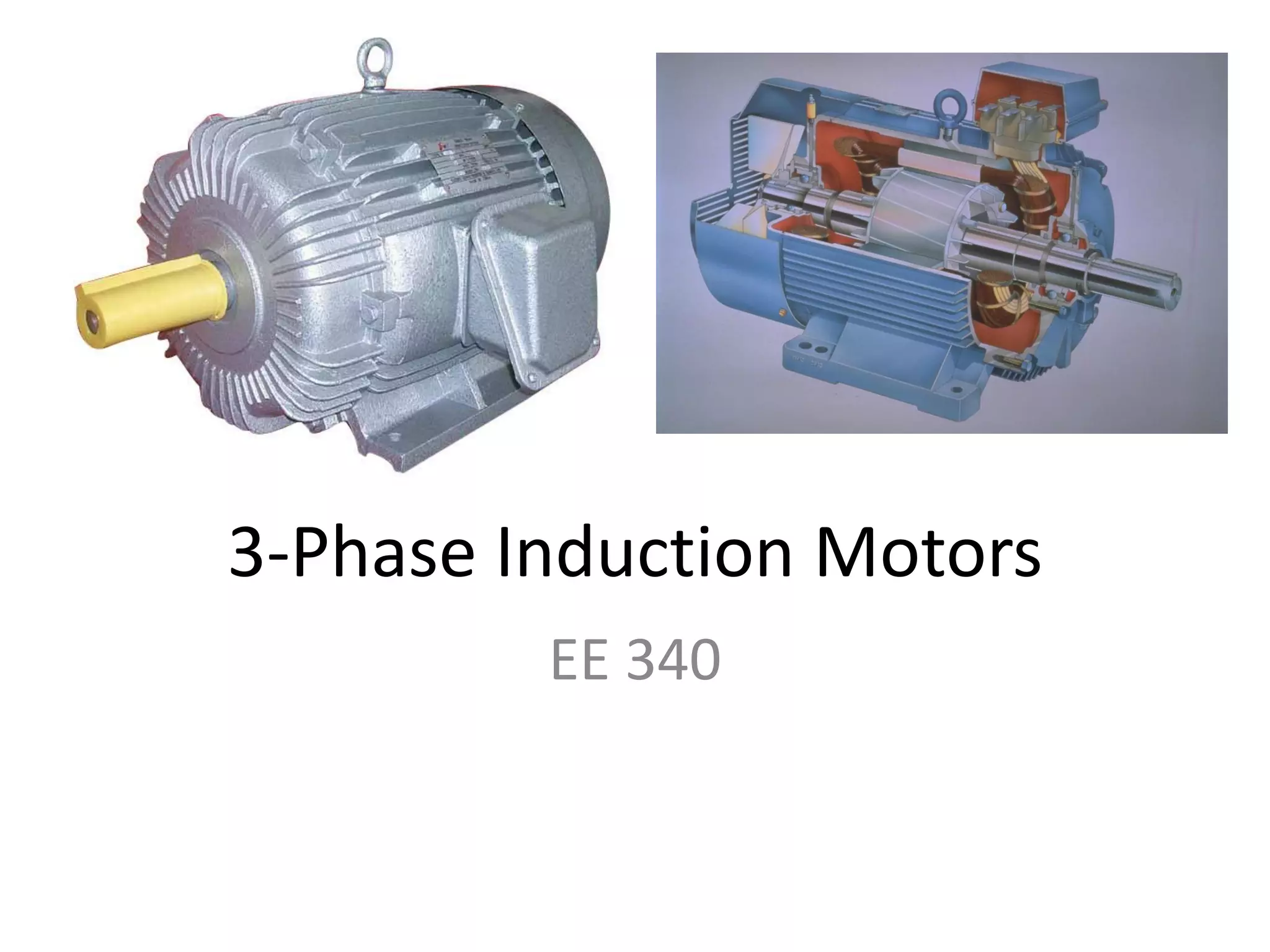

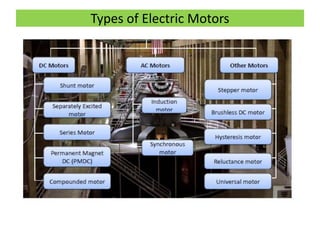

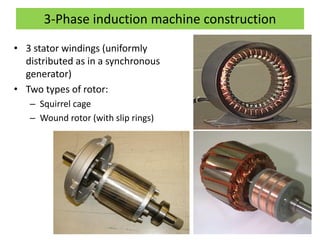

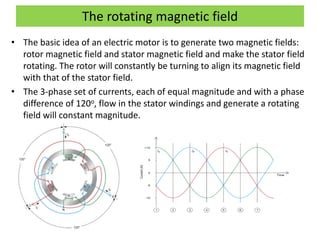

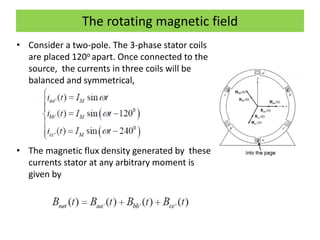

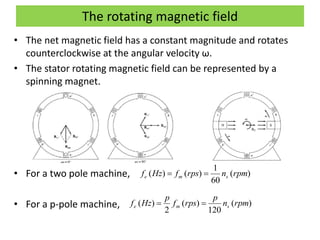

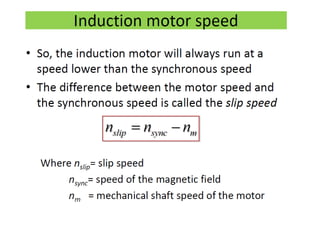

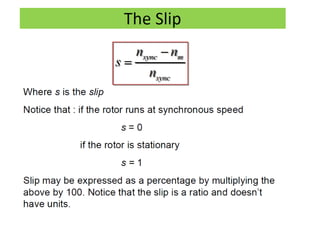

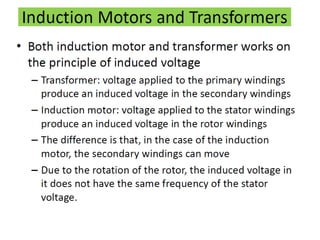

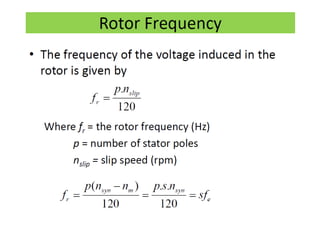

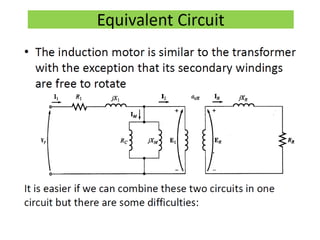

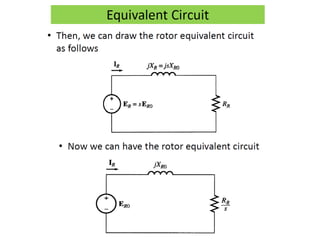

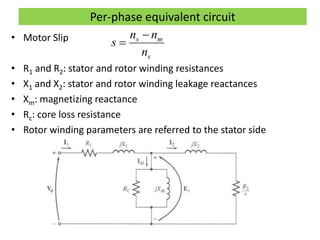

This document discusses 3-phase induction motors. It describes the construction of 3-phase induction motors, including their stator windings and two types of rotors: squirrel cage and wound rotor. It explains how the rotating magnetic field is generated by the 3-phase currents in the stator windings, causing the rotor to turn. Equivalent circuits are presented to model the motor, including per-phase and Thevenin equivalent circuits. The torque-speed curve and effect of varying rotor resistance are described. Methods for determining motor parameters from tests are provided.

![Power flow diagram

]/)1([3

3

)/(3

/3

3

2

2

2

2

2

2

2

2

2

2

1

1

2

1

SSRIPPP

RIP

SRIP

REp

RIP

RCLAGconv

RCL

AG

Ccore

SCL

](https://image.slidesharecdn.com/inductionmotors-200926110120/85/Induction-motors-17-320.jpg)