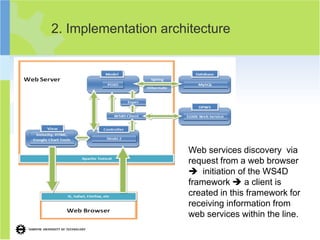

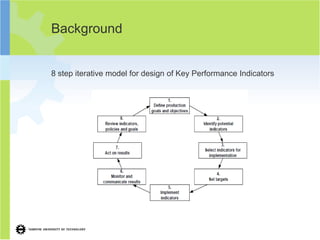

The document presents key performance indicators (KPIs) for energy-efficient asset management in a factory automation testbed, developed by researchers from Tampere University of Technology. It outlines the testbed setup, defines KPIs, and discusses the use of an event processing language for real-time data management and retrieval. Future work involves setting performance targets and developing alarm mechanisms for monitoring KPI thresholds.

![select a.cellId as cellId, a.dateTime

Cell ID,

as dateTime, b.AWATTHR as energy,

energy use

a.palletId as palletId

when the

from pattern [ every

robot starts

a=EquipmentChangeState

to execute,

(currentState="READY-

Energy use, pallet ID and

Energy PROCESSING-EXECUTING") ->

states of time stamp

consumption b=EnergyMeter(cellId=a.cellId)]

Unit energy consumption working cells,

for producing select a.cellId as cellId, a.dateTime

cell ID and Cell ID,

one product as dateTime, b.AWATTHR as energy,

pallet ID energy use

a.palletId as palletId

when the

from pattern [ every

robot stops to

a=EquipmentChangeState

execute,

(previousState="READY-

pallet ID and

PROCESSING-EXECUTING") ->

time stamp

b=EnergyMeter(cellId=a.cellId)]

select a.cellId as cellId, a.dateTime

Cell ID,

as dateTime, b.AWATTHR as energy,

energy use

a.processType as processType

when the

from pattern [ every

robot starts

a=EquipmentChangeState

to execute,

(currentState="READY-

process type

PROCESSING-EXECUTING") ->

Energy use, and time

b=EnergyMeter(cellId=a.cellId AND

Energy states of stamp

processType = a.processType)]

Process energy consumption consumption working cells,

select a.cellId as cellId, a.dateTime

per process type of process Cell ID,

as dateTime, b.AWATTHR as energy,

and cell ID energy use

a.processType as processType

when the

from pattern [ every

robot stops to

a=EquipmentChangeState

execute,

(previousState="READY-

process type

PROCESSING-EXECUTING") ->

and time

b=EnergyMeter(cellId=a.cellId AND

stamp

processType=a.processType)]](https://image.slidesharecdn.com/indin2012kpibincorinafinal-120813055030-phpapp01/85/Key-Performance-Indicators-for-Energy-Efficient-Asset-Management-in-a-Factory-Automation-Testbed-11-320.jpg)