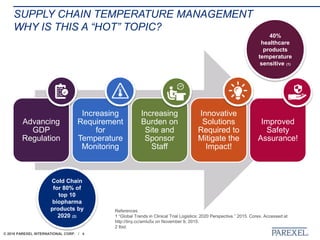

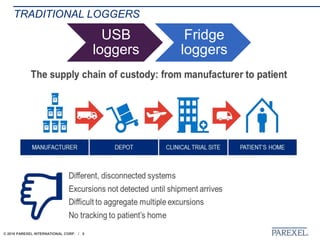

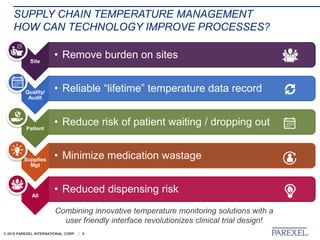

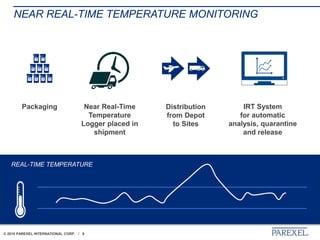

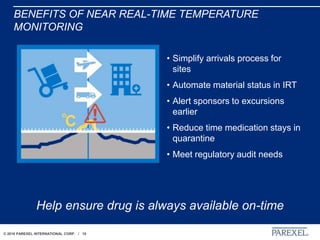

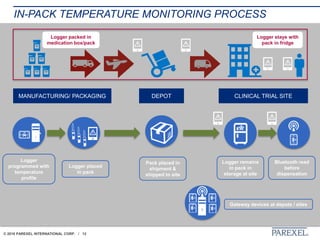

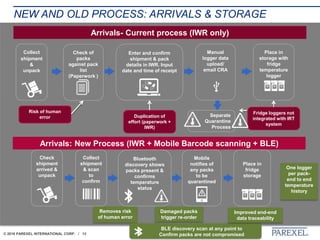

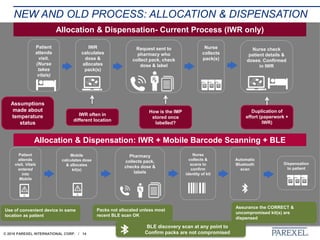

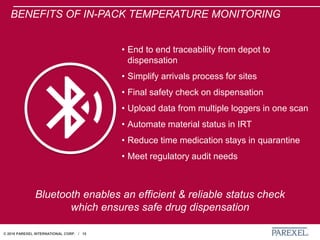

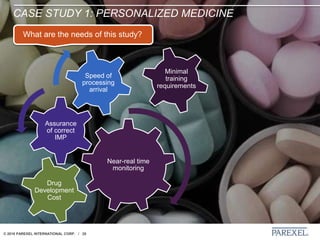

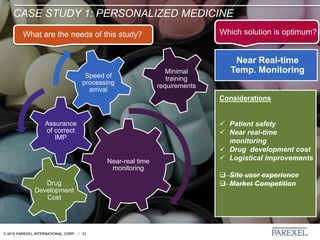

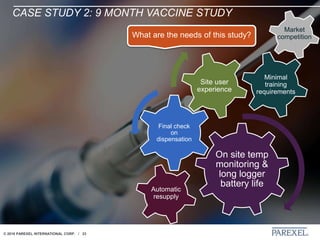

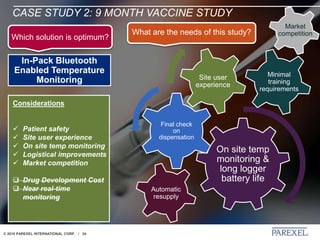

The document discusses the importance of temperature monitoring in clinical trials and explores traditional versus innovative methods for improving temperature traceability. It highlights the need for advanced solutions due to regulatory requirements and the impact on patient safety, showcasing case studies that demonstrate effective applications of near real-time and in-pack temperature monitoring technology. The conclusion emphasizes the necessity of selecting the right temperature management solution to streamline processes in clinical research.