💡 Boost Pharma Manufacturing & Supply Chain Performance with IoT Technology

Discover how IoT technology is transforming pharmaceutical manufacturing and supply chains by enabling real-time data, predictive analytics, and seamless connectivity. This content covers:

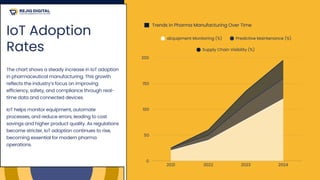

✅ Enhanced production efficiency through automated monitoring

✅ Predictive maintenance reducing costly downtime

✅ Improved supply chain visibility for better inventory management

✅ Integration of IoT with AI for smarter decision-making

✅ Real-world examples from leading pharma companies

🚀 Unlock new levels of operational excellence and compliance with IoT!

🔗 Read the full blog here: https://www.rejigdigital.com/blog/transforming-pharma-operations-how-iot-drives-efficiency-in-maintenance-manufacturing-and-the-supply-chain/