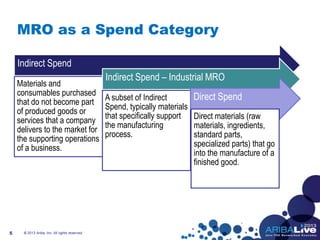

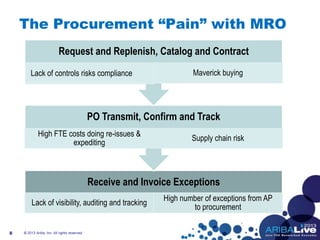

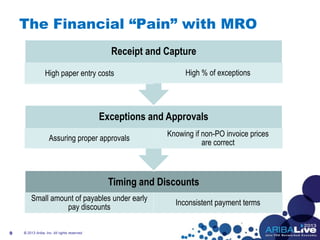

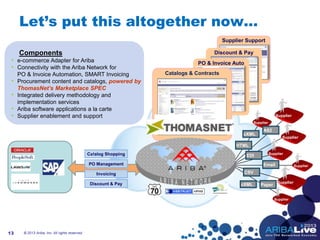

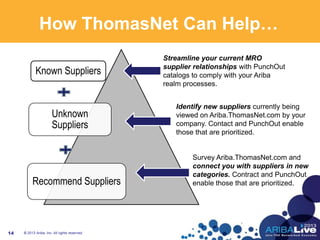

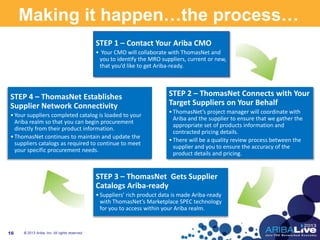

MRO (maintenance, repair, and operations) spending can generate thousands of documents and significant overhead costs. Leveraging existing Ariba investments and ThomasNet supplier catalogs and content can help capture more MRO spending and improve a company's bottom line. Partnering with ThomasNet allows companies to streamline MRO supplier relationships, identify new suppliers, and get supplier catalogs ready for procurement through Ariba to reduce costs.