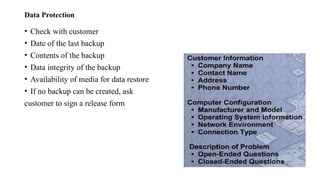

The document outlines maintenance procedures, emphasizing preventive maintenance to reduce downtime and repair costs, along with systematic troubleshooting methods. It details different types of maintenance such as reactive, preventive, predictive, and reliability-centered maintenance, and highlights the importance of documentation and staff orientation for effective maintenance operations. Additionally, it addresses occupational health and safety measures, ensuring a safe work environment during maintenance activities.