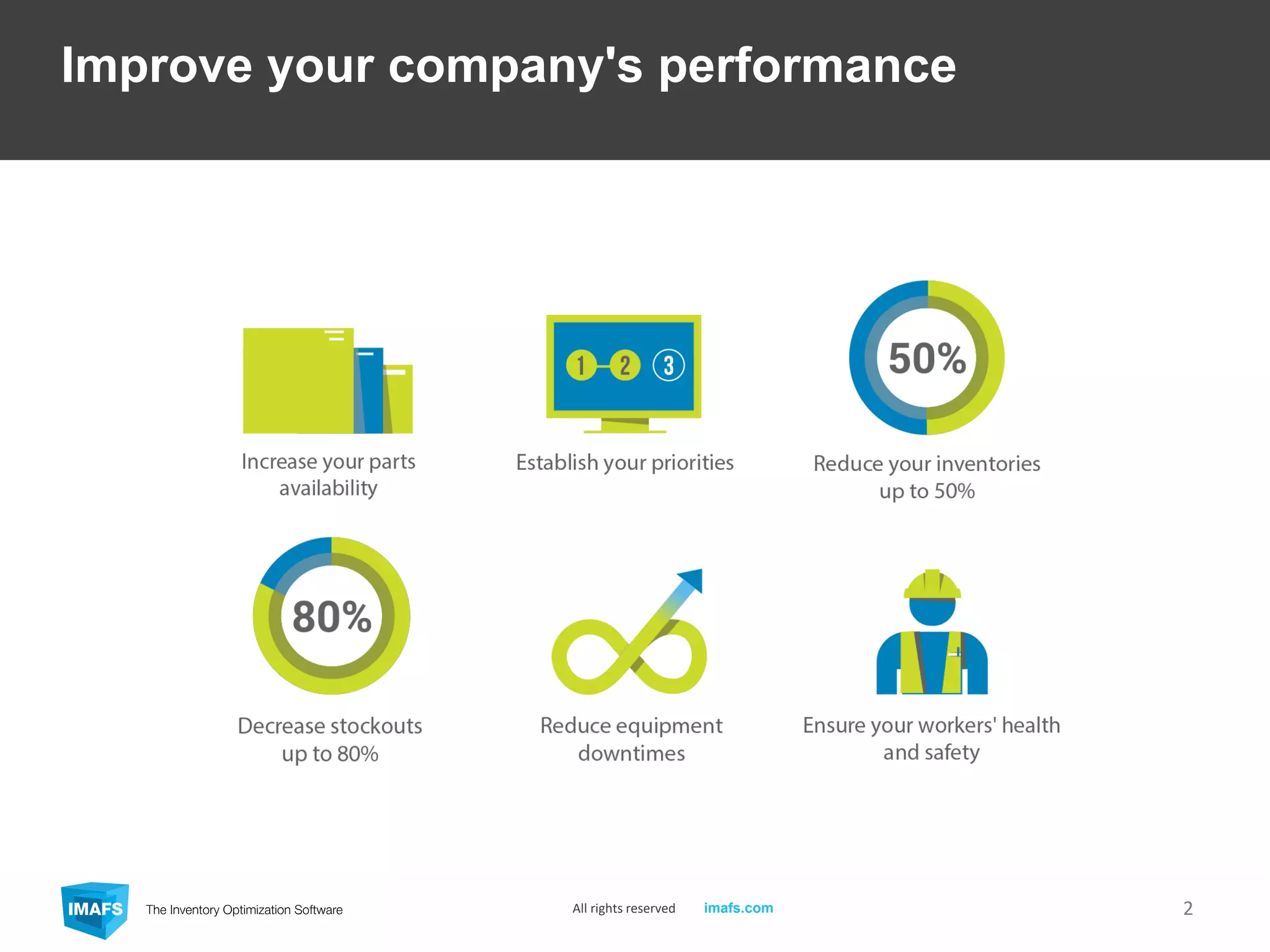

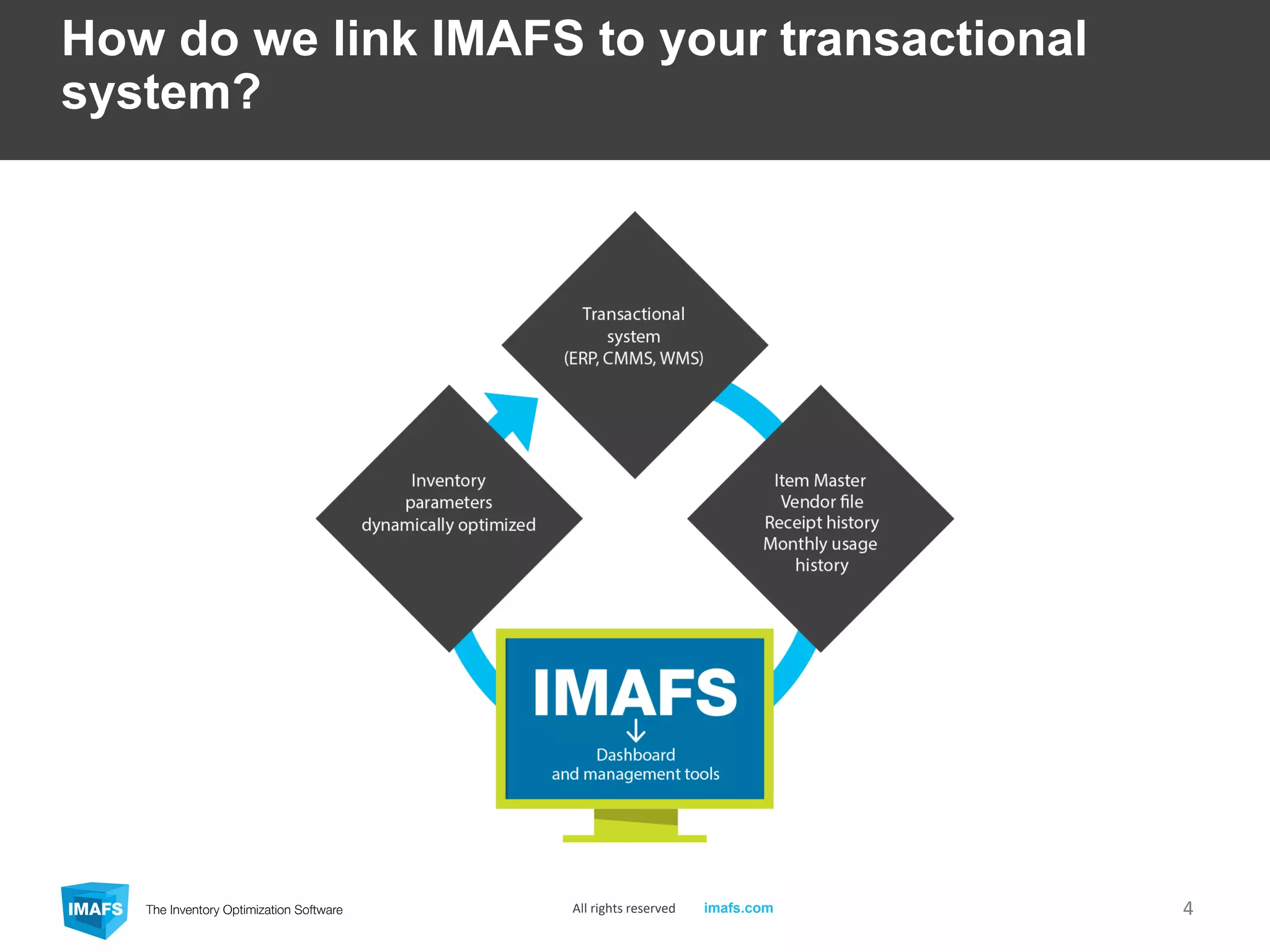

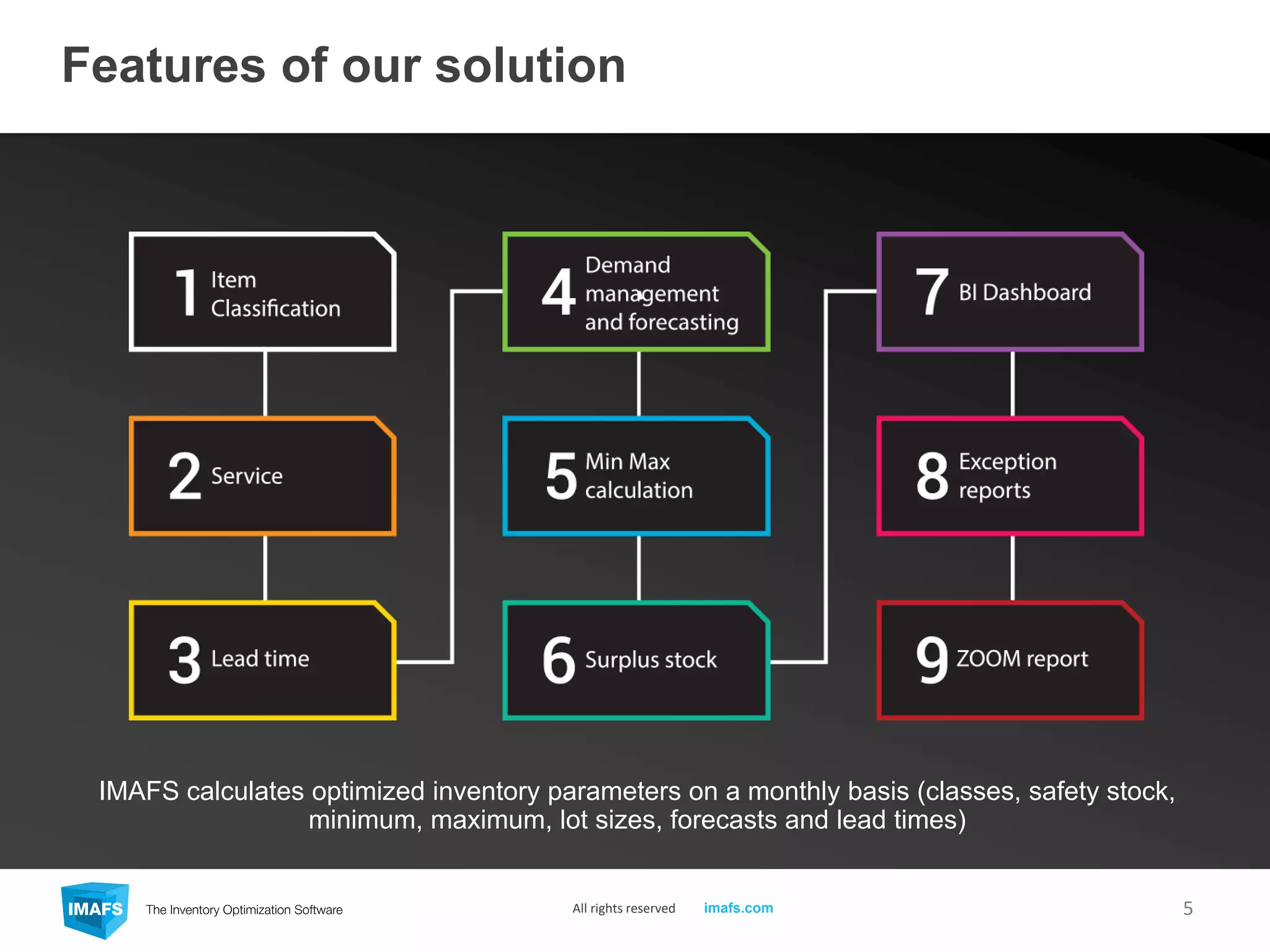

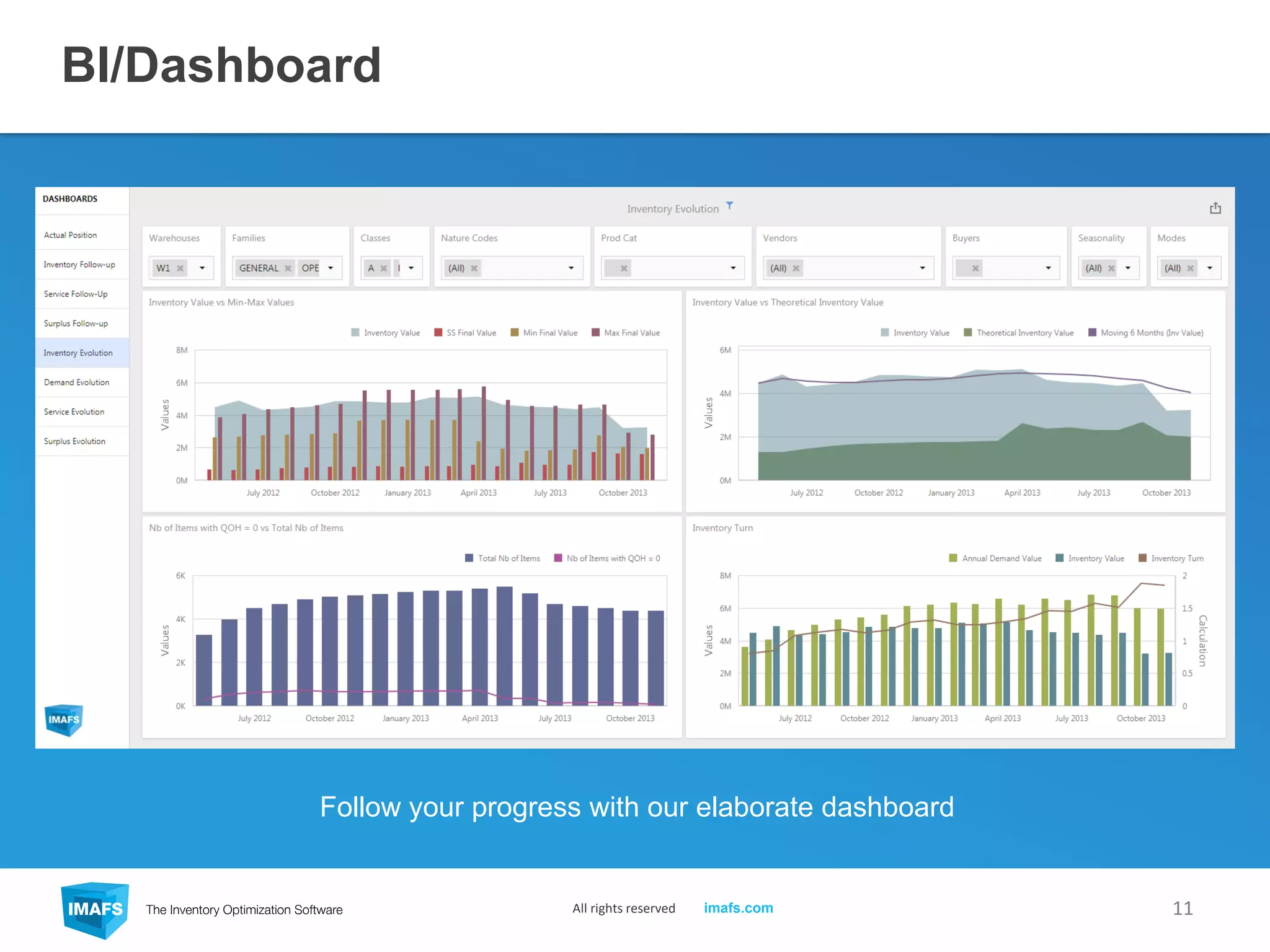

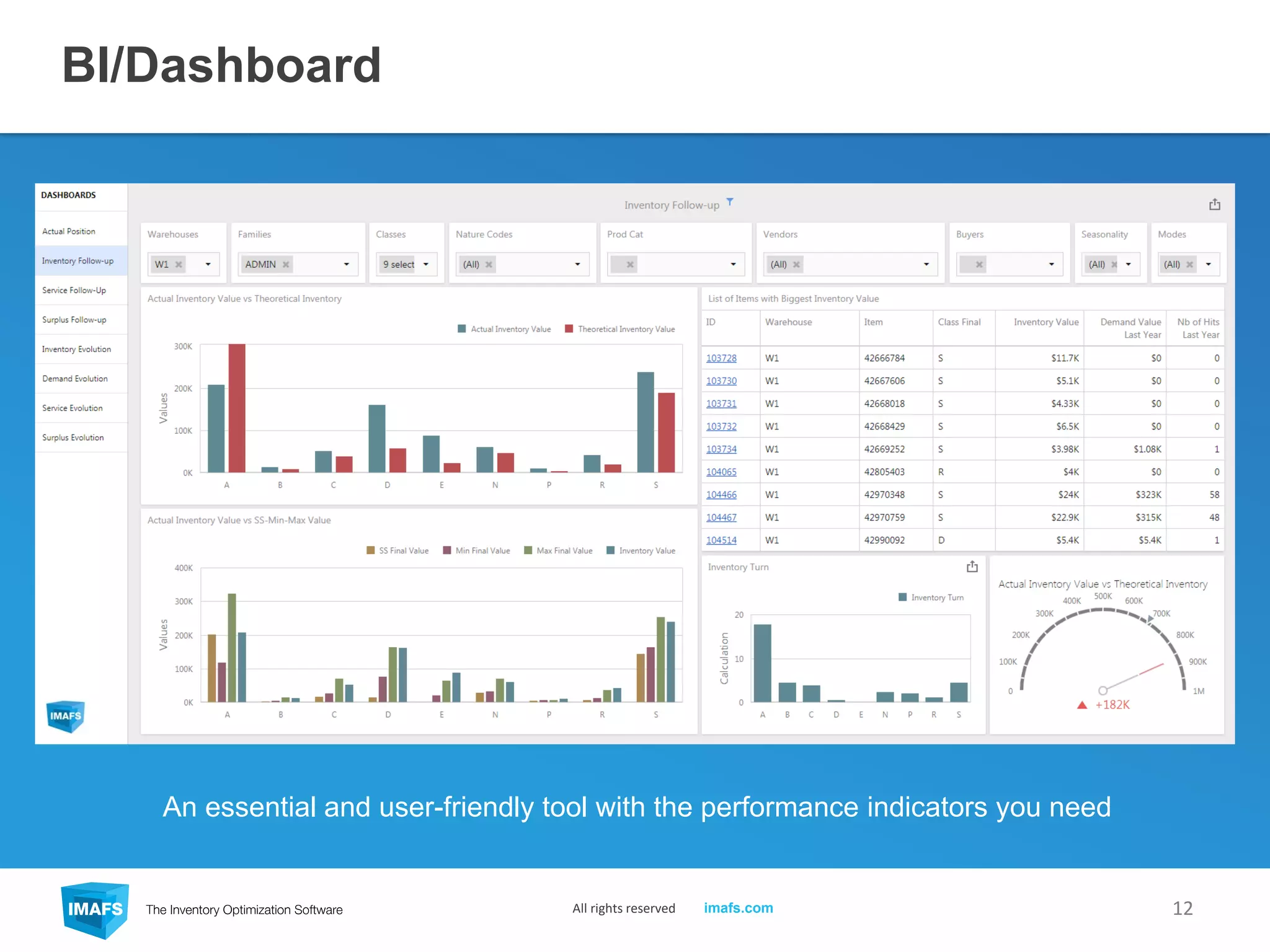

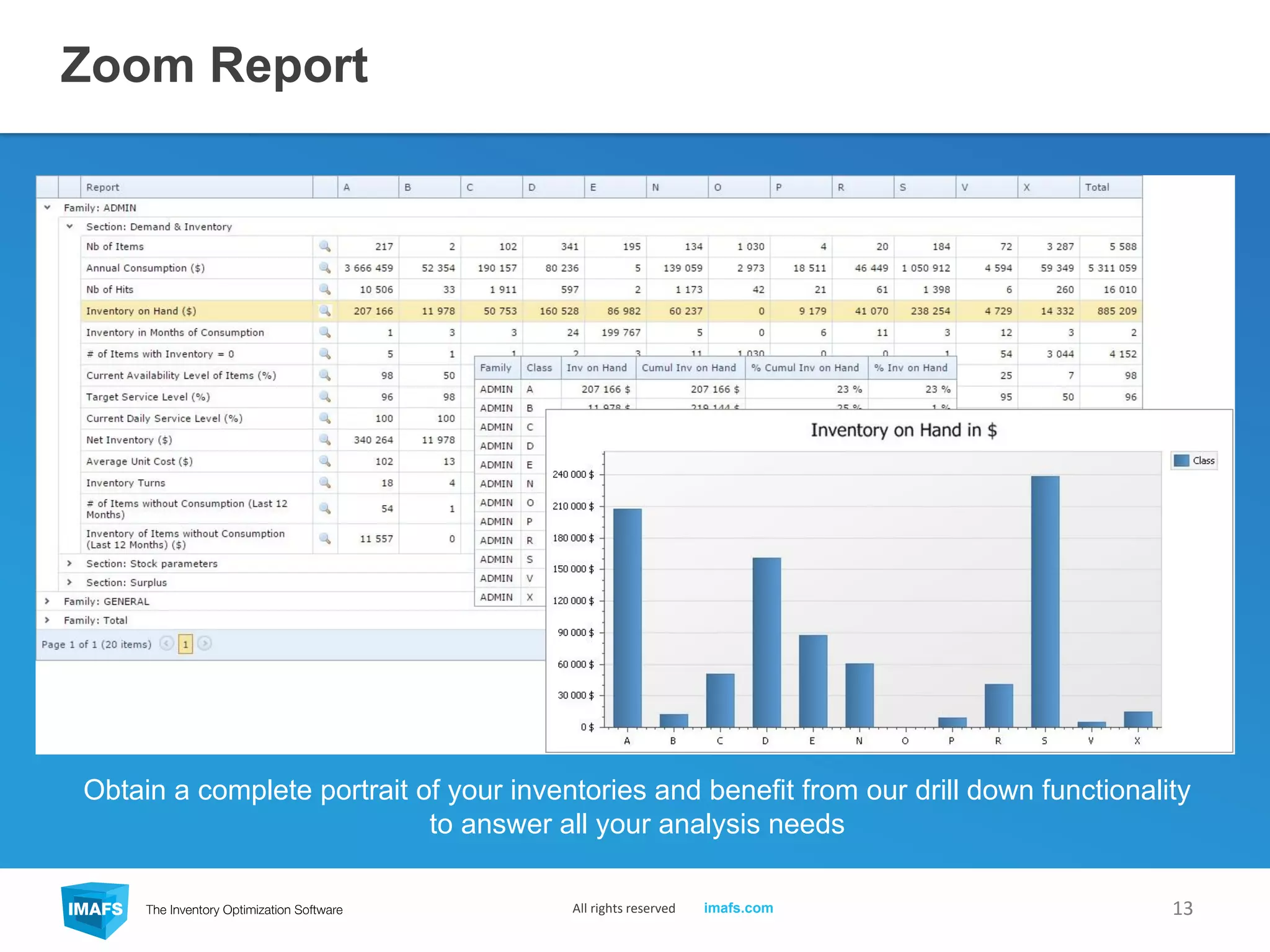

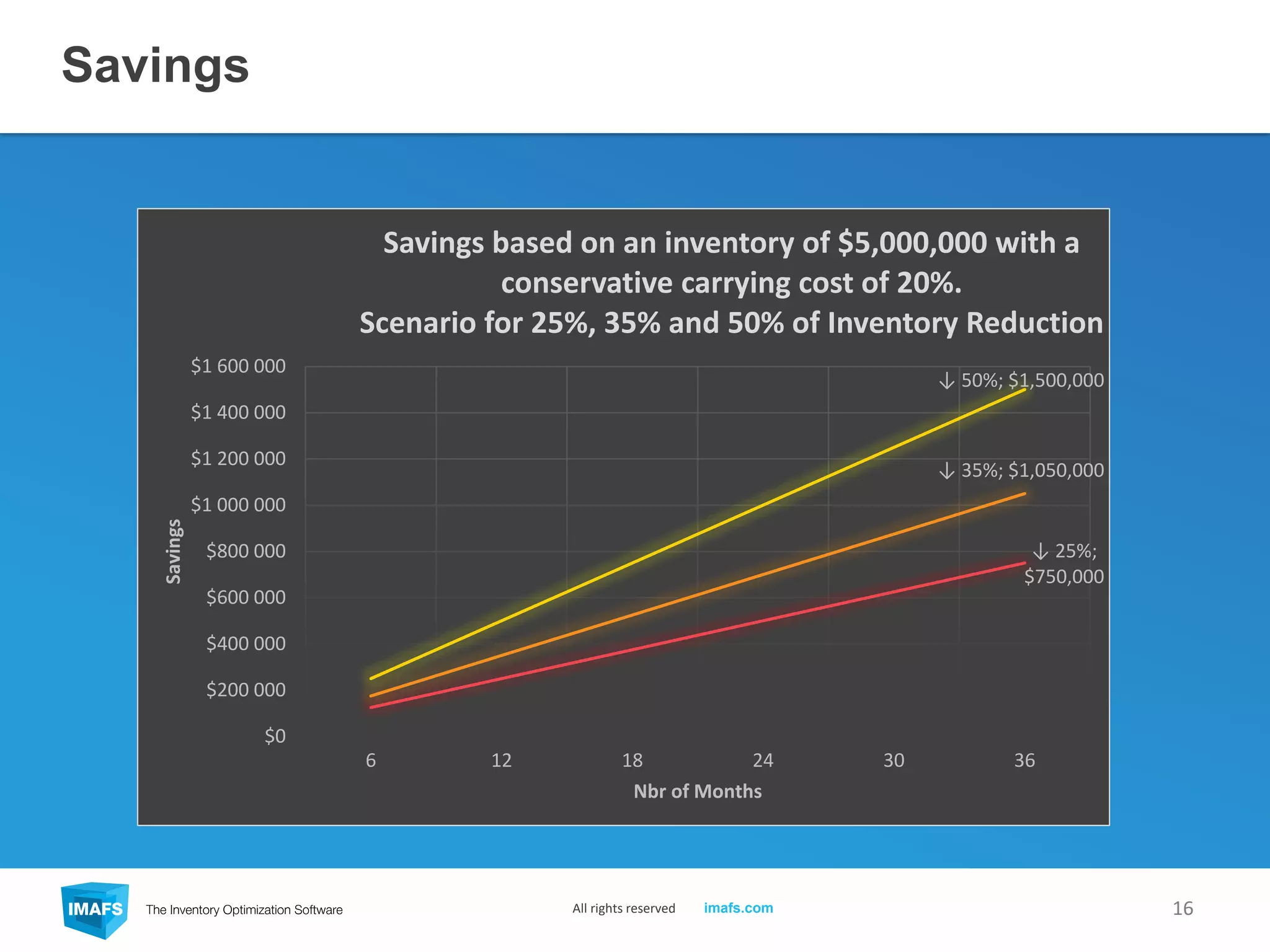

IMAFS provides an AI-powered inventory management solution designed to optimize stock levels while enhancing company performance. The software calculates inventory parameters and supports businesses in decision-making, leading to significant reductions in stock levels and improved service availability. Case studies show considerable inventory reductions and cost savings across various industries, demonstrating the effectiveness of the IMAFS system.