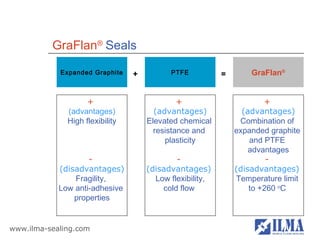

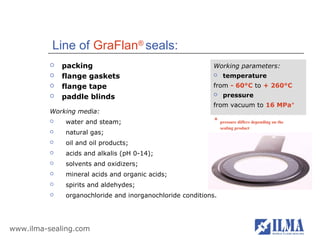

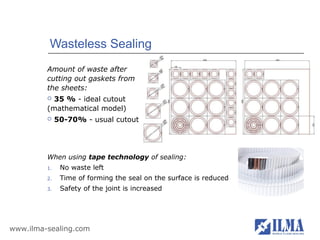

Ilma is a leading Russian company specializing in innovative sealing technologies with 17 years of experience in the sealing materials market. The company develops and manufactures high-efficient seals such as Graflan®, offering unique solutions for various industries and applications while prioritizing environmental safety and durability. Ilma's products are characterized by their reliability, reusability, and ability to perform under a wide range of conditions, catering to notable clients like Gazprom and Lukoil.