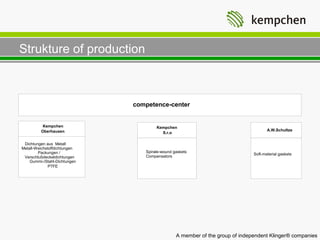

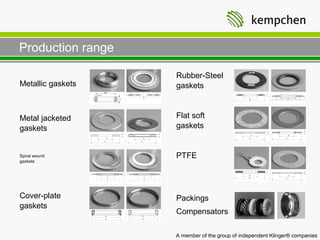

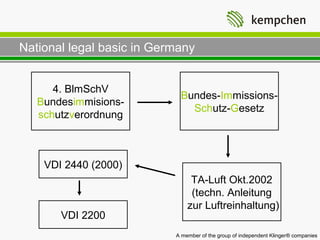

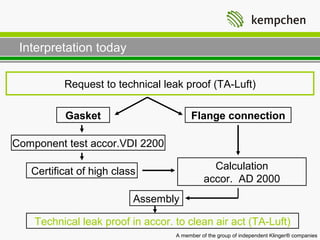

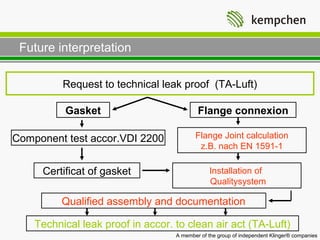

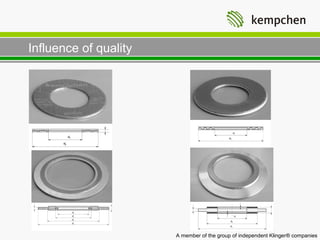

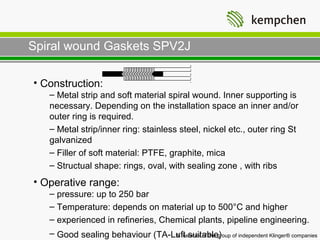

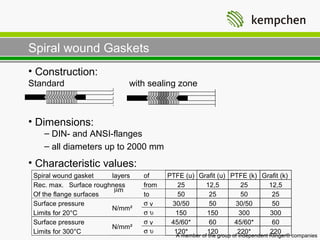

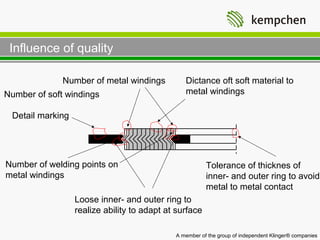

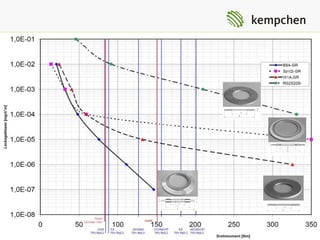

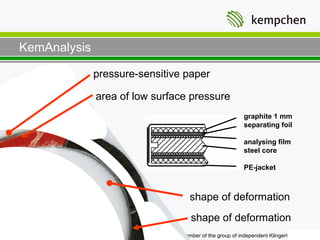

The document outlines the strategies and operational scope of Klinger® companies, focusing on industries such as chemical, petrochemical, and power generation. It covers product offerings, particularly in static gaskets, and emphasizes the importance of quality standards and performance assessments to minimize leakage and enhance environmental protection. Additionally, it details future interpretations of legal standards pertaining to gasket applications, such as the Clean Air Act and technical leak-proof requirements.