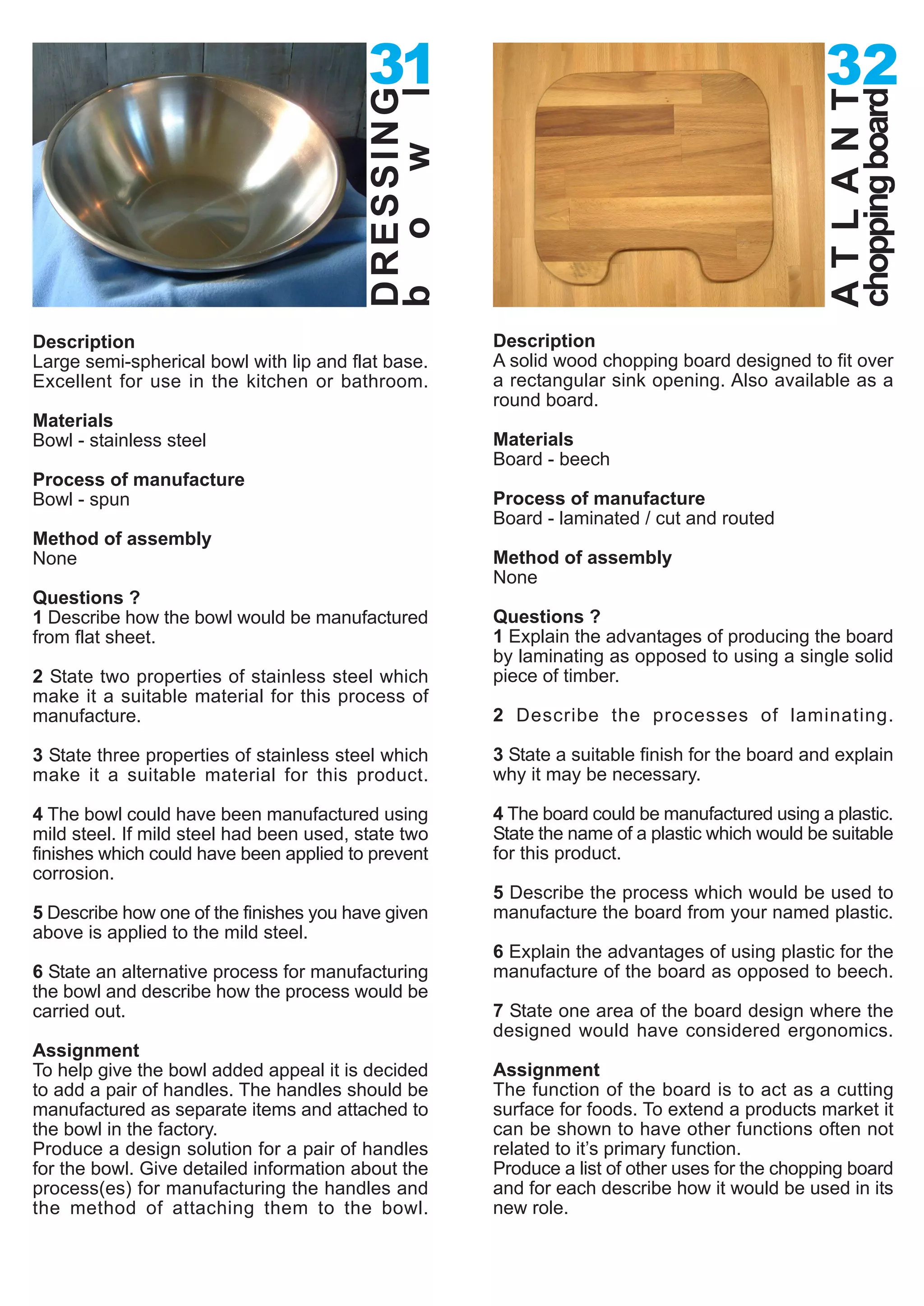

The document describes designs for several kitchen products including a bowl, chopping board, hanging rail, decoration, and chair. It provides details on the proposed materials, manufacturing processes, and design considerations for each item. Users are then given assignments to further develop some of the designs by adding new components or redesigning parts of the products.